If the flow right up to the UFH Tee is => 60Deg then the blending valve isn't doing it job, if you can't get the mix temp up to 50deg'ish. How do you know the blended temp, is there a gauge on the manifold? Was it just left like this or has this just happened since the commissioning and hand over?

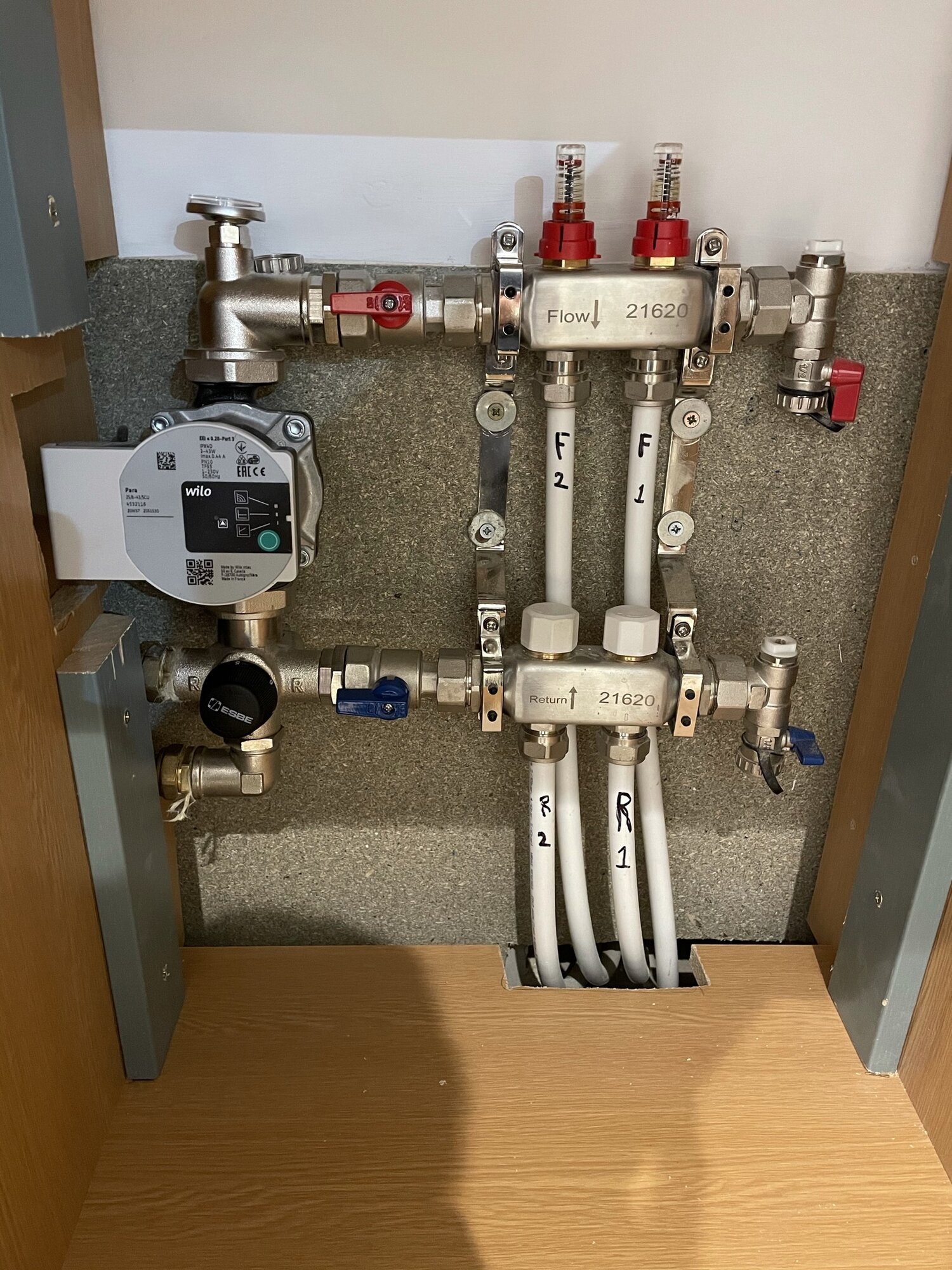

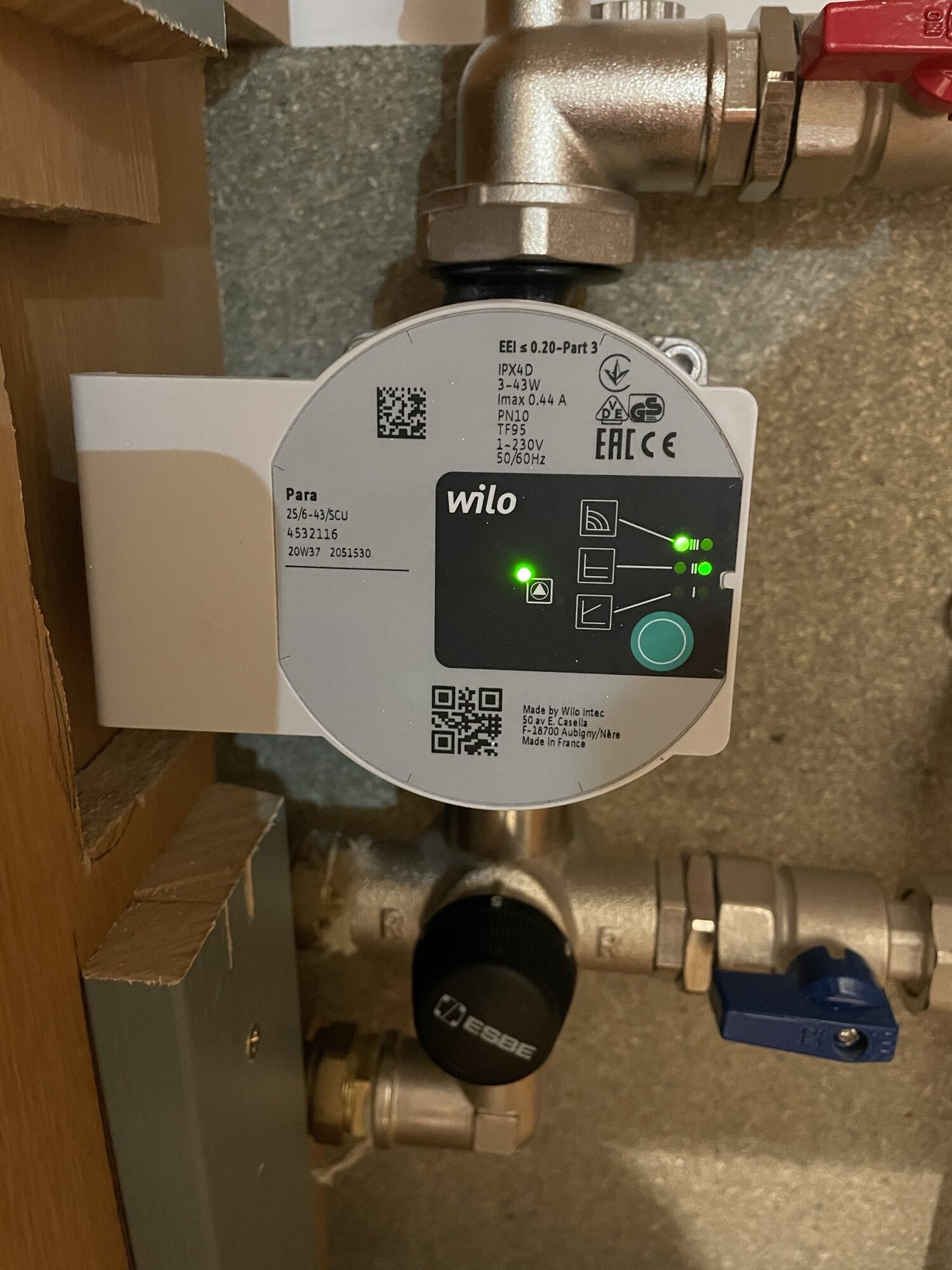

A pic of the manifold/setup would be good What are the flow valves set to?

A pic of the manifold/setup would be good What are the flow valves set to?