You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

UFH pipes not hot enough

- Thread starter windsortg

- Start date

thanks @Johntheo5. Things have been pretty hectic lately. I will look to find out the setting of d.05. What I have done since last posting is getting back the CORGI engineer who replaced 90% of my radiators in the house back in April this year together with replacing the old Grundfos pump with a new Grundfos UPS2 25-80 pump. He said that with the introduction of an UFH system and having 20 rads throughout the house, the new pump was necessary to ensure sufficient flow of water was being maintained through the heating system.

The engineer used a thermometer device which had clamps to connect to the flow & return pipework at the top of the boiler. When the heating was turned on, he could see the flow temp shoot up, the temp differential quickly go over 20C and the s.53 code appeared.

The engineer power flushed the 22/28mm flow & return pipework that runs from the Vaillant boiler (located in the garage) to the landing cupboard where the Grundfos pump, megaflo, and zone valves are located. He also checked to see if the Grundos pump was mechanically working by removing the screw at the front of the pump and slightly pushing a screwdriver into the pump while the pump was running. He said that if the pump stopped turning by the insertion of the screwdriver, the pump was defective. The pump did though continue turning so he does not believe there is a problem with the pump. He also removed part of the pump and he could rotate it freely with his hand.

After finishing the power flush, the heating ran successfully for about 3 hours. All the rads heated up as expected. However, after about 3 hours by which time the engineer had left, I noticed the temp in my lounge had gone cool and when feeling the rads, they were cool. When I checked the boiler, it showed s.53 .

.

When I explained this to the engineer, he believes there is some blockage in the heating pipework. He spoke with Vaillant and they share the same theory. The engineer has ordered a new power flush unit which he says is more appropriate in power flushing the number of power rads I have. He plans to do a power flush on my heating system in a couple of weeks time.

One thing I have not got round to doing is running the UFH system on its own to see if this also triggers an s.53. In the meantime, I have reduced d.00 to 18. I currently find that the heating runs for longer and the nearest rads to the Grundfos pump are getting hot but the rads furthest away from the pump are cool/luke warm. I am not totally convinced there is a blockage .

.

I think I mentioned before but when the UFH system was installed in the summer, whenever the UFH system ran, it would open the zone valve of the radiator heating system (as well as the UFH zone valve). The house would be roasting which showed the main heating system was working perfectly! At the time, I had the Tado heating control system and in consultation with Tado, they said it was a limitation in their product to be able to separately control 3 zone valves (1 for the heating, 1 for UFH, 1 for hot water). Last month, this engineer came to replace the Tado heating control system with a Heatmiser system. This entailed removing the Tado extension kit and 2 Tado room stats (one wireless stat which controlled the heating system and one hard-wired stat which controlled the UFH), and replacing these with 3 Heatmiser wired stats (one as a program stat for hot water, one therm stat for heating, one therm stat for UFH). This may be a pure coincidence but ever since Heatmiser was installed, I've been having this s.53 problem and rads not getting hot. I mentioned this to the engineer but he said introducing Heatmiser would not be causing the issue I am facing. Could there be any wiring issue that may be affecting the Grunfos pump from running properly and therefore not pushing the water fast enough through the system?

I will run the UFH system on its own to see if this brings up s.53 on the boiler. If it does, I am assuming the problem lies either with the boiler (which is 13 years old), the 6-month Grundfos pump, or a blockage somewhere between the pipework from the boiler to the zone valves/Grundfos pump.

Is there anything else I can go before the engineer returns to carry out a power flush on the main heating system?

The engineer used a thermometer device which had clamps to connect to the flow & return pipework at the top of the boiler. When the heating was turned on, he could see the flow temp shoot up, the temp differential quickly go over 20C and the s.53 code appeared.

The engineer power flushed the 22/28mm flow & return pipework that runs from the Vaillant boiler (located in the garage) to the landing cupboard where the Grundfos pump, megaflo, and zone valves are located. He also checked to see if the Grundos pump was mechanically working by removing the screw at the front of the pump and slightly pushing a screwdriver into the pump while the pump was running. He said that if the pump stopped turning by the insertion of the screwdriver, the pump was defective. The pump did though continue turning so he does not believe there is a problem with the pump. He also removed part of the pump and he could rotate it freely with his hand.

After finishing the power flush, the heating ran successfully for about 3 hours. All the rads heated up as expected. However, after about 3 hours by which time the engineer had left, I noticed the temp in my lounge had gone cool and when feeling the rads, they were cool. When I checked the boiler, it showed s.53

When I explained this to the engineer, he believes there is some blockage in the heating pipework. He spoke with Vaillant and they share the same theory. The engineer has ordered a new power flush unit which he says is more appropriate in power flushing the number of power rads I have. He plans to do a power flush on my heating system in a couple of weeks time.

One thing I have not got round to doing is running the UFH system on its own to see if this also triggers an s.53. In the meantime, I have reduced d.00 to 18. I currently find that the heating runs for longer and the nearest rads to the Grundfos pump are getting hot but the rads furthest away from the pump are cool/luke warm. I am not totally convinced there is a blockage

I think I mentioned before but when the UFH system was installed in the summer, whenever the UFH system ran, it would open the zone valve of the radiator heating system (as well as the UFH zone valve). The house would be roasting which showed the main heating system was working perfectly! At the time, I had the Tado heating control system and in consultation with Tado, they said it was a limitation in their product to be able to separately control 3 zone valves (1 for the heating, 1 for UFH, 1 for hot water). Last month, this engineer came to replace the Tado heating control system with a Heatmiser system. This entailed removing the Tado extension kit and 2 Tado room stats (one wireless stat which controlled the heating system and one hard-wired stat which controlled the UFH), and replacing these with 3 Heatmiser wired stats (one as a program stat for hot water, one therm stat for heating, one therm stat for UFH). This may be a pure coincidence but ever since Heatmiser was installed, I've been having this s.53 problem and rads not getting hot. I mentioned this to the engineer but he said introducing Heatmiser would not be causing the issue I am facing. Could there be any wiring issue that may be affecting the Grunfos pump from running properly and therefore not pushing the water fast enough through the system?

I will run the UFH system on its own to see if this brings up s.53 on the boiler. If it does, I am assuming the problem lies either with the boiler (which is 13 years old), the 6-month Grundfos pump, or a blockage somewhere between the pipework from the boiler to the zone valves/Grundfos pump.

Is there anything else I can go before the engineer returns to carry out a power flush on the main heating system?

@Johntheo5 - d.05 is 65

@Johntheo5 - d.05 is 65

Can you change the UPS2 25-80-180 setting from III to I (6M)

Fire up the boiler to rads only and keep watching d.40&d.41, d.40 should reach 65c and boiler should continue to run.

Does the boiler also have its own internal pump??. see 3.11.1, if so, see what d.19 is showing.

What is the make/model/setting of the manifold pump

Is this the pump that was replaced.

Last edited:

thanks @Johntheo5. I am back home tomorrow and so will adjust the pump setting to I.

When I am testing the behaviour of the boiler, I fire up just the rads. I have not tried the UFH for quite some time now mainly because the weather has been mild and with the sun coming through into the orangery, this room with the UFH has generally stayed warm. The photo you attached in your last post is the new pump that was installed 6 months ago. The old pump was a Grundfos 15-60 I believe.

When I fire up the boiler, I will see d.40 & d.41 to see how far they get to.

I am not aware whether the boiler has an internal pump. When the engineer removed the front cover of the boiler, I did not see any pump. Looking at the online manual https://www.vaillant.co.uk/downloads/z/ecotec/ecotec-installation-servicing-2007-372783.pdf and the photo of the boiler on page 9, it appears the pump is behind the electronics box. I will look to see if I can get behind the electronics box. If there is a pump, I will see what d.19 is showing.

Where you ask about the make/model of the manifold pump, stupid question but do you mean the manifold pump of the UFH system? If so, from the attached photo, it is a Grundfos UPM3 Auto. From the photo, are you able to see the setting of the pump?

When I am testing the behaviour of the boiler, I fire up just the rads. I have not tried the UFH for quite some time now mainly because the weather has been mild and with the sun coming through into the orangery, this room with the UFH has generally stayed warm. The photo you attached in your last post is the new pump that was installed 6 months ago. The old pump was a Grundfos 15-60 I believe.

When I fire up the boiler, I will see d.40 & d.41 to see how far they get to.

I am not aware whether the boiler has an internal pump. When the engineer removed the front cover of the boiler, I did not see any pump. Looking at the online manual https://www.vaillant.co.uk/downloads/z/ecotec/ecotec-installation-servicing-2007-372783.pdf and the photo of the boiler on page 9, it appears the pump is behind the electronics box. I will look to see if I can get behind the electronics box. If there is a pump, I will see what d.19 is showing.

Where you ask about the make/model of the manifold pump, stupid question but do you mean the manifold pump of the UFH system? If so, from the attached photo, it is a Grundfos UPM3 Auto. From the photo, are you able to see the setting of the pump?

Attachments

The manifold pump UPM3 is set to its maximum CP (constant pressure) mode but thats for another day as you want to sort out the rad problem first.

The S.53 code is interesting as it comes up due to water shortage, don't know what VL-RL is but alot of boilers use the pressure rise when the pump starts up and runs as the trigger for this so one would expect that this would relate to a boiler with a internal pump, wonder what vaillant's response would be. S.54 will annunciate if the flow/return is too high, probably around 30C so circulation rate, at least, doesn't seem to be a problem.

The S.53 code is interesting as it comes up due to water shortage, don't know what VL-RL is but alot of boilers use the pressure rise when the pump starts up and runs as the trigger for this so one would expect that this would relate to a boiler with a internal pump, wonder what vaillant's response would be. S.54 will annunciate if the flow/return is too high, probably around 30C so circulation rate, at least, doesn't seem to be a problem.

thanks @Johntheo5. While I try to sort out the rad issue first, one thing I also want to do is to test the UFH system but running this on its own. If this also causes an s.53 on the boiler, then I am thinking this would rule out the theory of their being a blockage in the rad system which is reducing the water flow. The return & flow to the UFH manifold has been taken from the landing cupboard where the Grundfos UPS2 25-80 and zone valves are located. This is all new pipework to the groundfloor where the UFH manifold is.

Is there a potential issue with the manifold pump being set to maximum CP?

Is there a potential issue with the manifold pump being set to maximum CP?

Manifold pump setting: I would think the pressure (head) from both the UPS (8M) pump and the manifold pump should be reasonably close to allow rhe TMV to work properly, the UPS on its max setting (8M) will pump up to 55LPM (3.3m3/hr) at that head, the manifold pump is possibly around 5M on max CP setting. (don't have pump curves).

I'd say most systems run quite happily at pump heads of 3/3.5M.

I'd say most systems run quite happily at pump heads of 3/3.5M.

thanks @Johntheo5. Stupid question but what does TMV mean? Do I need to do anything to the manifold pump setting?

The TMV is the thermostatic mixing valve which mixes the hot water (65C in your case) with the far colder return water from the UFH manifold loops to give the required mixing temperaturre, if you have the TMV set to 45C then the returm might be 35C so you have boiler water at 65C mixing with manifold return water at 35C to give the required mixed temperature of 45C.

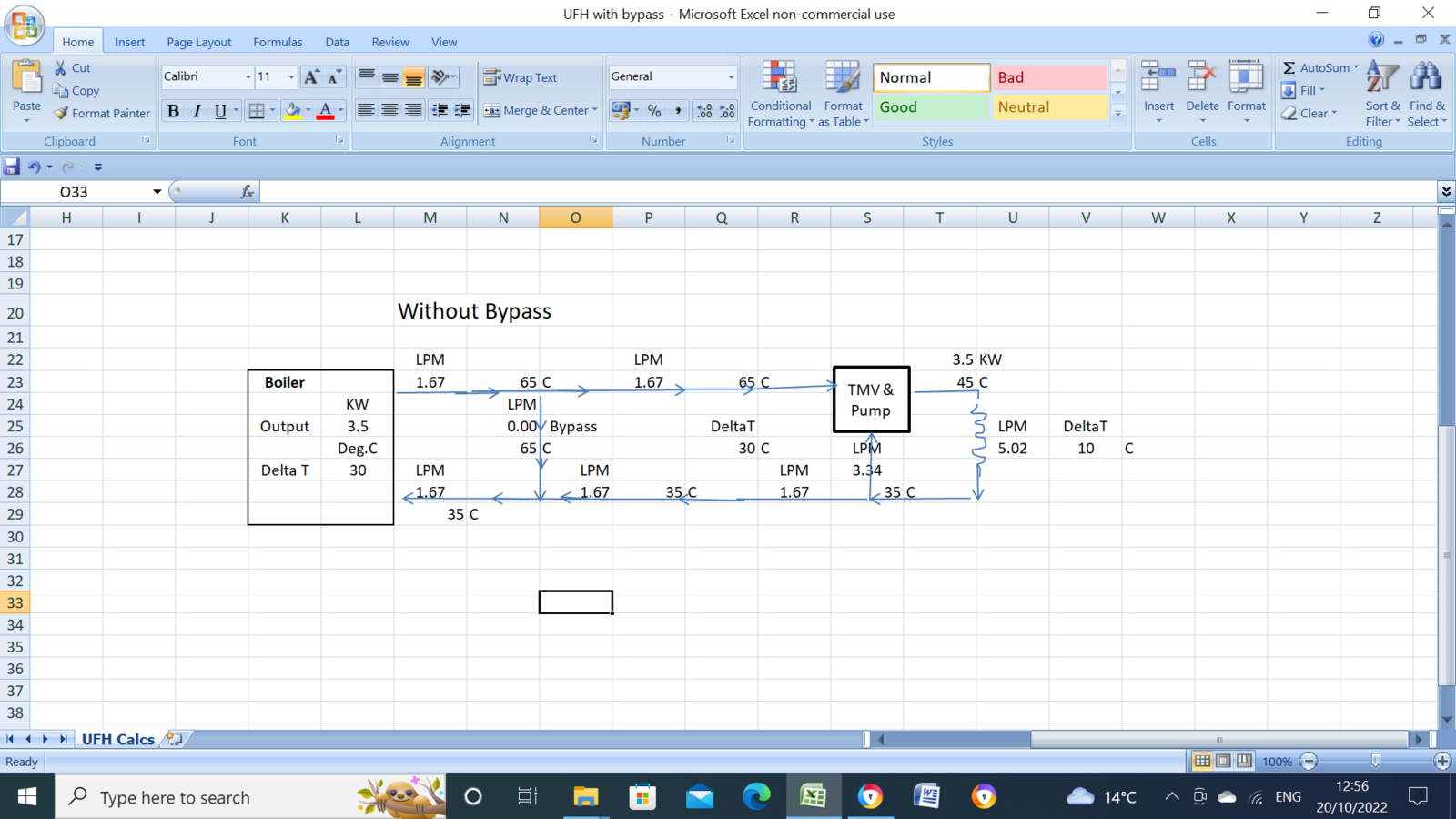

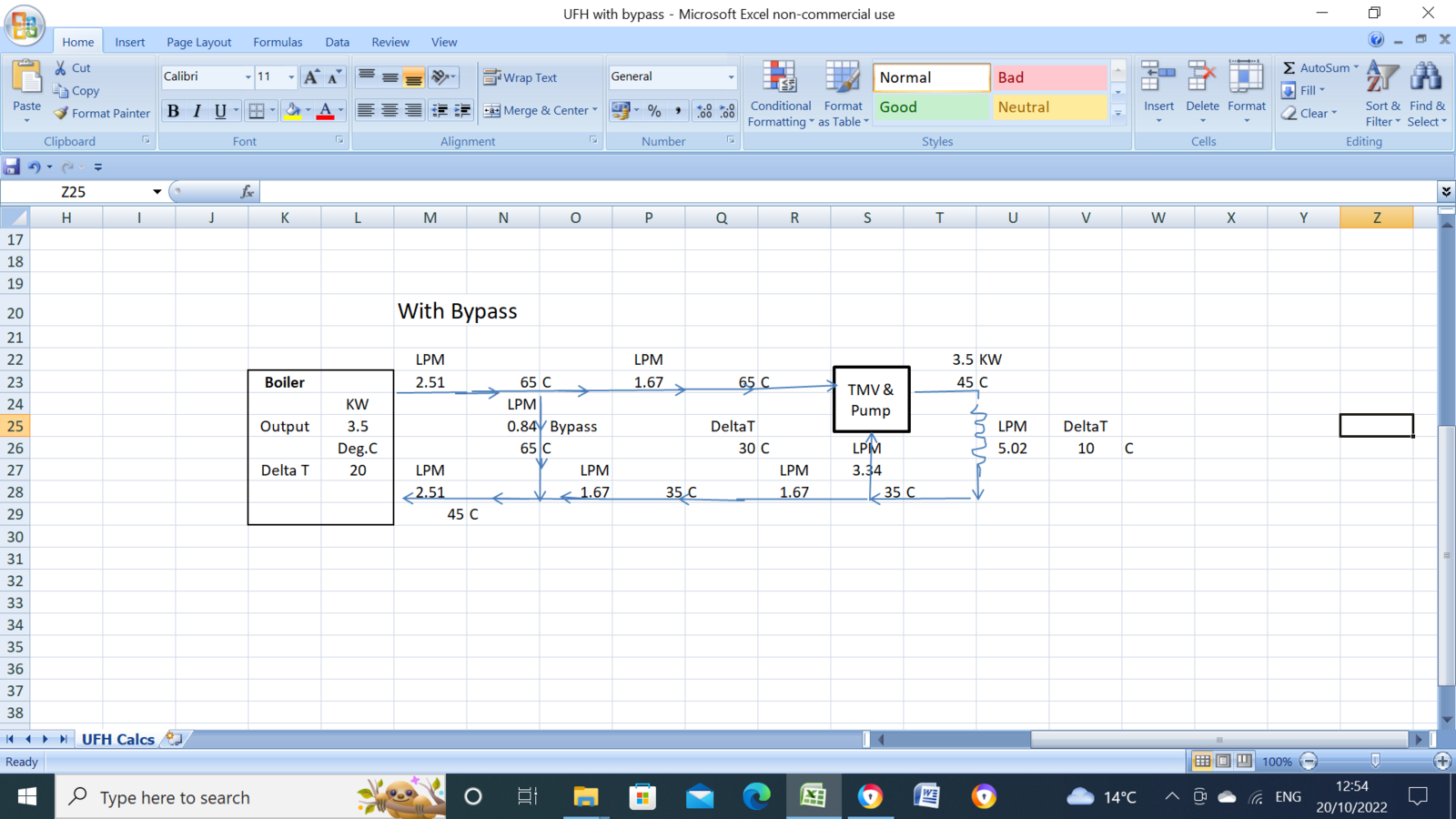

You have 2 loops circulating 5LPM, assuming a manifild dT of 10C (45-35) then the UFH requiremant is 3.5kw and you will have 1.67LPM boiler flow @65C mixing with 3.34LPM manifold to give just over 5LPM @ 45C to the manifold, the remaining 1.67LPM (boiler return & flow LPM must be the same) returns to the boiler at 35C, this gives a boiler dT of 30C (65-35), which the boiler will not be happy with and probably cause S.53, there ways of bypassing some of the boiler flow to its return to give a dT of say 20C, a bypass of 0.84LPM at 65c will raise the return temp at the boiler to 45C giving a boiler dT of 20c but your boiler cannot run continuously at a output of 3.5kw so snookered anyway except that the cycling boiler can do the job, very unlikely with a vaillant IMO.

The attached might show the various flows/temps etc without and with by pass.

You have 2 loops circulating 5LPM, assuming a manifild dT of 10C (45-35) then the UFH requiremant is 3.5kw and you will have 1.67LPM boiler flow @65C mixing with 3.34LPM manifold to give just over 5LPM @ 45C to the manifold, the remaining 1.67LPM (boiler return & flow LPM must be the same) returns to the boiler at 35C, this gives a boiler dT of 30C (65-35), which the boiler will not be happy with and probably cause S.53, there ways of bypassing some of the boiler flow to its return to give a dT of say 20C, a bypass of 0.84LPM at 65c will raise the return temp at the boiler to 45C giving a boiler dT of 20c but your boiler cannot run continuously at a output of 3.5kw so snookered anyway except that the cycling boiler can do the job, very unlikely with a vaillant IMO.

The attached might show the various flows/temps etc without and with by pass.

thanks @Johntheo5. Is the TMV the blending valve on the UFH manifold? If so, this is set at 45C. From the info you shared, is there anything I need to do with the settings on the UFH or am I likely to experience issues with the UFH I have based on how things are currently set up?

ok @Johntheo5. Sorry if you have already mentioned this but what do I need to do to reduce the boiler dT to below 30C? Is it to sort out the current problem that I'm having with the rad system?

What can I do to increase the UFH demand to prevent boiler cycling? If there is an issue with my existing Vaillant ecoTEC plus 438 boiler, my engineer recommends replacing this the Vaillant ecoTEC plus 637

What can I do to increase the UFH demand to prevent boiler cycling? If there is an issue with my existing Vaillant ecoTEC plus 438 boiler, my engineer recommends replacing this the Vaillant ecoTEC plus 637

Suggest ringing Vaillant and ask them the value of the dT that flags the S.53,

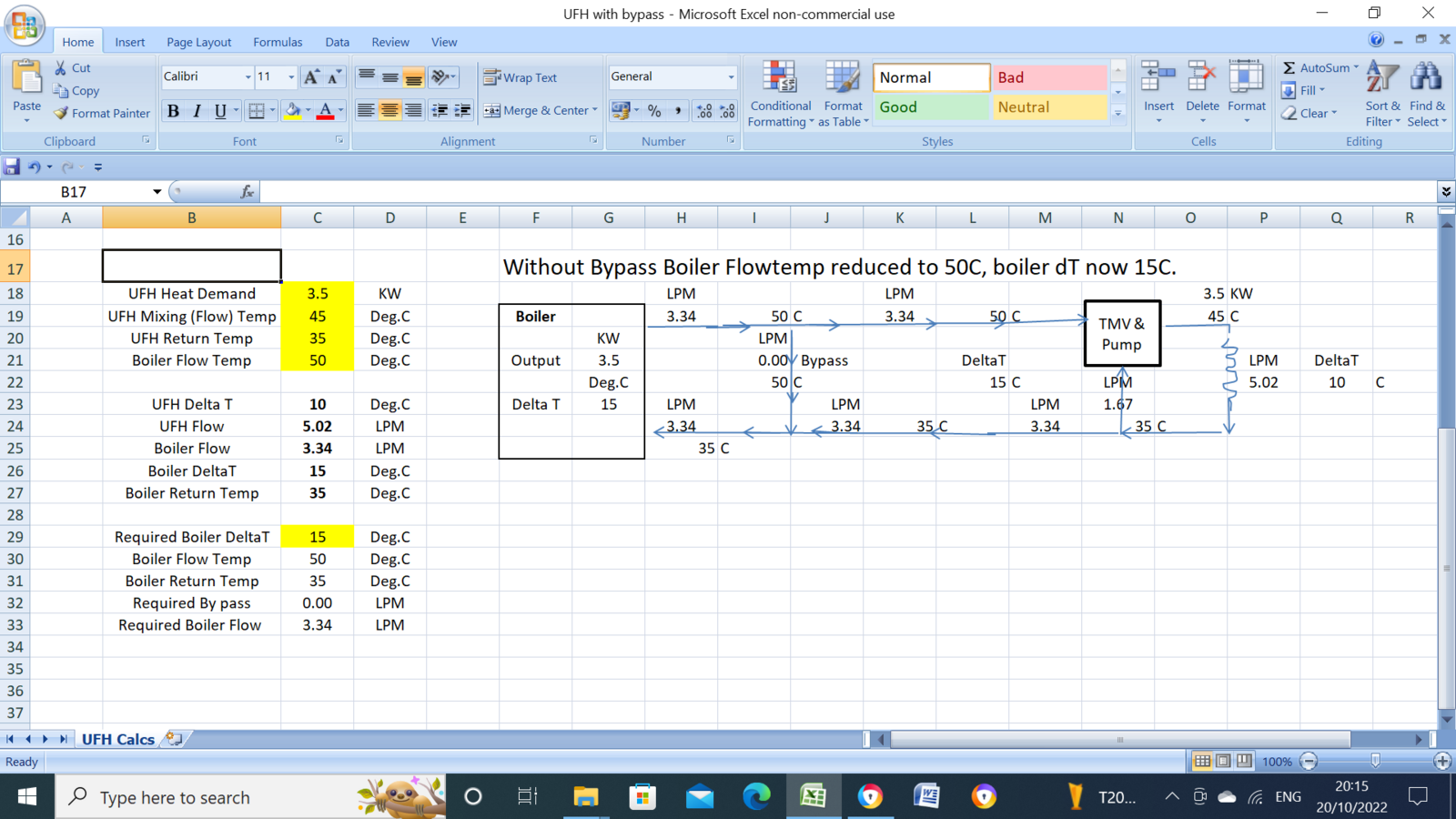

You can reduce the dT when running on UFH only, by reducing the boiler flow temperature, reducing the flow temp to 50C will reduce the dT to 15C. (see below)

You may be able to increase the heat emitted by the UFH loops by increasing the mixed flow temperature but you have to be careful not to damage the floor covering but as the minimum output of the boiler is ~ 5.5/6kw then no way IMO can you stop cycling and any Vaillant would be at the bottom of my list where cycling is involved, based on reading problems other users have.

You can reduce the dT when running on UFH only, by reducing the boiler flow temperature, reducing the flow temp to 50C will reduce the dT to 15C. (see below)

You may be able to increase the heat emitted by the UFH loops by increasing the mixed flow temperature but you have to be careful not to damage the floor covering but as the minimum output of the boiler is ~ 5.5/6kw then no way IMO can you stop cycling and any Vaillant would be at the bottom of my list where cycling is involved, based on reading problems other users have.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 5

- Views

- 5K

- Replies

- 11

- Views

- 2K

- Replies

- 3

- Views

- 3K

D