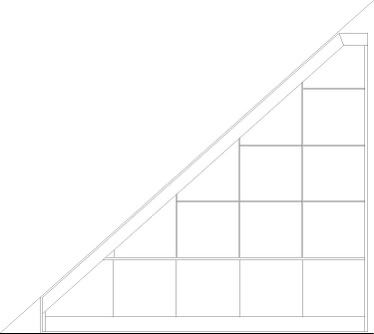

I plan to build a cupboard under the angled stairway in my narrow hall which will have an area behind the shelves for storage. The under-stair recess is sloped to floor level at one end and 2.05M high (ceiling height) at the other. Width 230. Depth 90cm. (see illustrations below - not to scale)

I had thought about building a softwood frame and boxing that in with ply but now believe I could use 18mm MDF instead (any thoughts?)

I want to front the cupboard with shelves facing the passage to display my glass collection - preferably on glass shelves underlit with halogens. I also intend to create an access door at the open end - hinged at the wall.

My main issue is that the dog-leg configuration of the hallway means it may necessary to be able to move the sehlf section back into the stairway recesss in order to get large objects past (e.g. a Sofa) to back of the flat.

Therefore I am looking something that can be locked in place to the floor and stairs but moved into the recess as needed. I thought of either floor tracks or castors that can be locked when required.

The door to the storage area will be hinged from the wall so that the cupboard is separate and also it will fold back out of the way when required.

The floor is smooth laminate.

Questions

1. Is MDF suitable for this and if so - what should I use to join it for strength/looks.

2. Would locking castors be enough to hold the unit it in place or should I look at floor/ceiling bolts as well.

3. Would a track work better than castors

Any suggestions for suppliers or solutions would be welcomed.

Regards

Paul

I had thought about building a softwood frame and boxing that in with ply but now believe I could use 18mm MDF instead (any thoughts?)

I want to front the cupboard with shelves facing the passage to display my glass collection - preferably on glass shelves underlit with halogens. I also intend to create an access door at the open end - hinged at the wall.

My main issue is that the dog-leg configuration of the hallway means it may necessary to be able to move the sehlf section back into the stairway recesss in order to get large objects past (e.g. a Sofa) to back of the flat.

Therefore I am looking something that can be locked in place to the floor and stairs but moved into the recess as needed. I thought of either floor tracks or castors that can be locked when required.

The door to the storage area will be hinged from the wall so that the cupboard is separate and also it will fold back out of the way when required.

The floor is smooth laminate.

Questions

1. Is MDF suitable for this and if so - what should I use to join it for strength/looks.

2. Would locking castors be enough to hold the unit it in place or should I look at floor/ceiling bolts as well.

3. Would a track work better than castors

Any suggestions for suppliers or solutions would be welcomed.

Regards

Paul