- Joined

- 11 Jan 2004

- Messages

- 170

- Reaction score

- 4

- Country

Hello,

I take part at trade shows and want to replace my existing halogen lighting with 50w led floodlights(as image) The lights will be positioned high up behind fascia boards shining down onto the tables set up around the front edge of my stand . Obviously although the lights have a very long life once in a while they will fail and I may need to replace one or two quickly to keep the stand and products well lit.

I am always on a corner and will have two floodlights on each side of the stand shining down and would like the lights in pairs to be connected to one long cable going to the socket(i.e two cable overall going to wall socket.

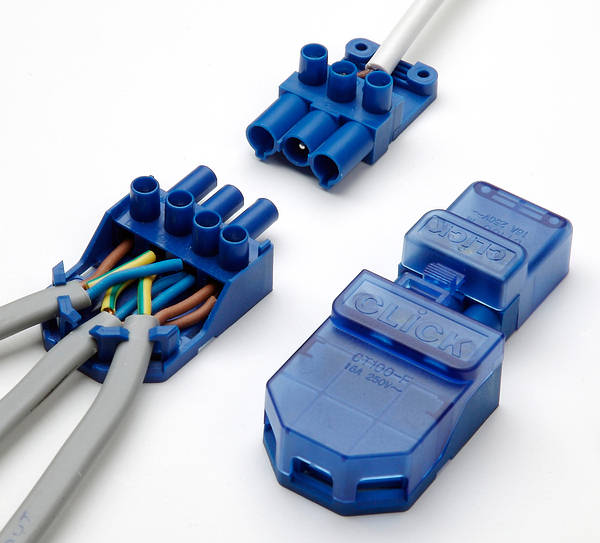

Firstly can I connect to 50w leds to one cable and secondly is it possible to have each one connected so that it can be quickly "unplugged " and another plugged in to replace it if it fails.Obviously I could just use a very long extension cable with three pin sockets but extensions of this sort are not allowed over 6 feet.

I.e are there male female connectors that are safe and would work in this situation. I hope that all makes sense !

Thanks.

I take part at trade shows and want to replace my existing halogen lighting with 50w led floodlights(as image) The lights will be positioned high up behind fascia boards shining down onto the tables set up around the front edge of my stand . Obviously although the lights have a very long life once in a while they will fail and I may need to replace one or two quickly to keep the stand and products well lit.

I am always on a corner and will have two floodlights on each side of the stand shining down and would like the lights in pairs to be connected to one long cable going to the socket(i.e two cable overall going to wall socket.

Firstly can I connect to 50w leds to one cable and secondly is it possible to have each one connected so that it can be quickly "unplugged " and another plugged in to replace it if it fails.Obviously I could just use a very long extension cable with three pin sockets but extensions of this sort are not allowed over 6 feet.

I.e are there male female connectors that are safe and would work in this situation. I hope that all makes sense !

Thanks.