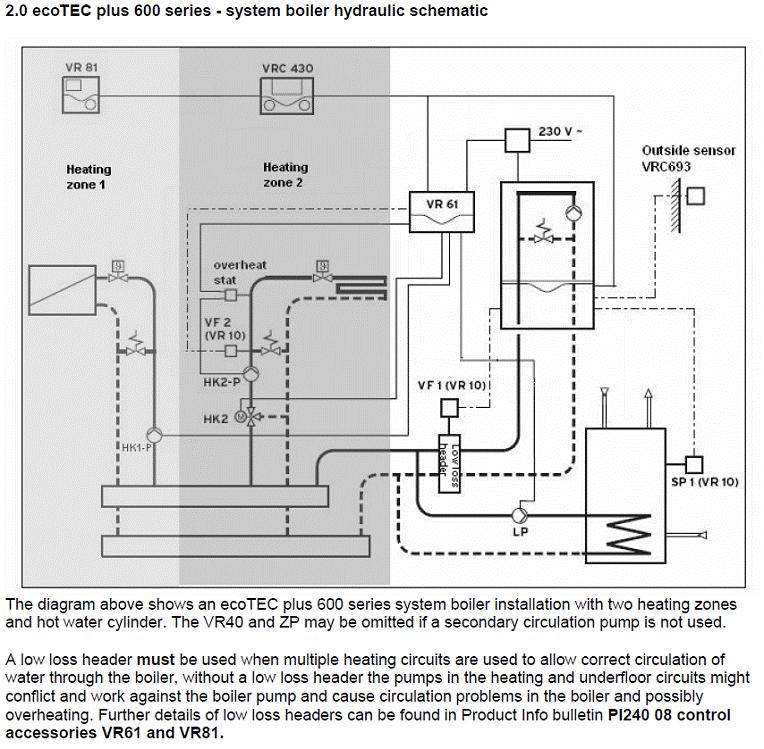

Sounds like like your system needs a LLH, as already suggested.

You could have a header with a 15/60 as the shunt pump (between the boiler and header)

Then a single Magna 25/80 powering the whole system on the other side of the header (no other pumps)

Or you could have smaller pumps, one for each circuit.

Depends how much money you want to spend!

You could have a header with a 15/60 as the shunt pump (between the boiler and header)

Then a single Magna 25/80 powering the whole system on the other side of the header (no other pumps)

Or you could have smaller pumps, one for each circuit.

Depends how much money you want to spend!