Firstly, I must say I am not conversant with this cylinder, but as it appears to be based on a thermal store, the radiators should be connected to the heating circuit outlets on the cylinder (5 & 6), the boiler/stove flow and returns to the post heating connections (1 & 2), whilst the solar connections are 3 & 4. Hence my belief that the boiler and stove need to be plumbed together before the cylinder as my previous post..

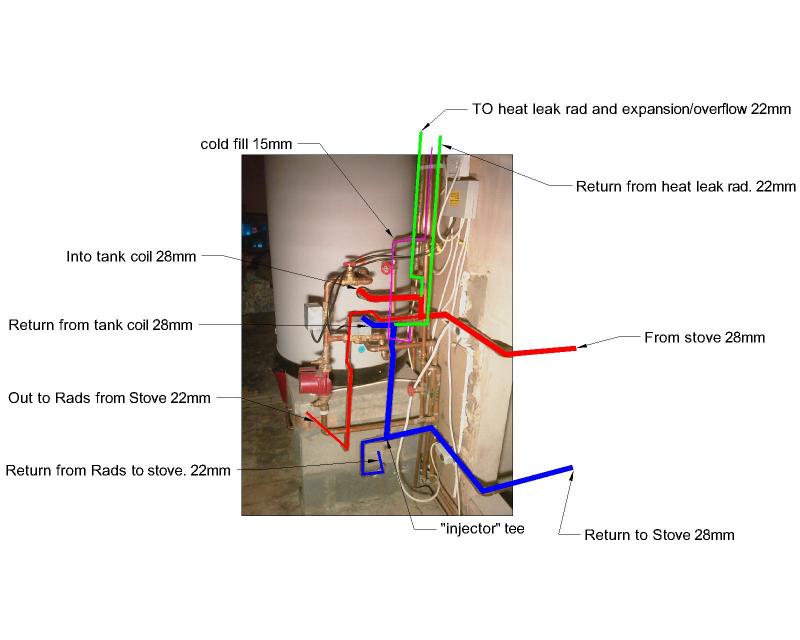

Because of the lack of hot water I would be loathed to plumb the rads into the tank, there is little enough DHW as it is!. No, the rads tee off before the tank and the high stat kicks in the CH pump at 90 deg C on the gravity flow from the stove to the tank. Theorectically an "injector tee" on the return draws SOME hot water through the DHW tank to keep a flow to the DHW to avoid robbing all the heat away from the tank.

It does mean the woodstove and hot tank are plumbed in parallel but one problem is the CH pump reverses the gravity flow through the tank when it kicks in?? (injector tee not working?) ....and I don't think you could put a one way valve in a gravity circ??

Driving me insane... and the plumber wants ME to take time off work to show HIM whats wrong with the system!!!!