I have a feeling my existing pump is a potterton .... considering that the prima 40F boiler, (original) programmers and 9 radiators are.

Looking for a drop in replacement is showing a few different units with a very wide price range. Please which would be ideal one to go for ?. A pic below if it helps.

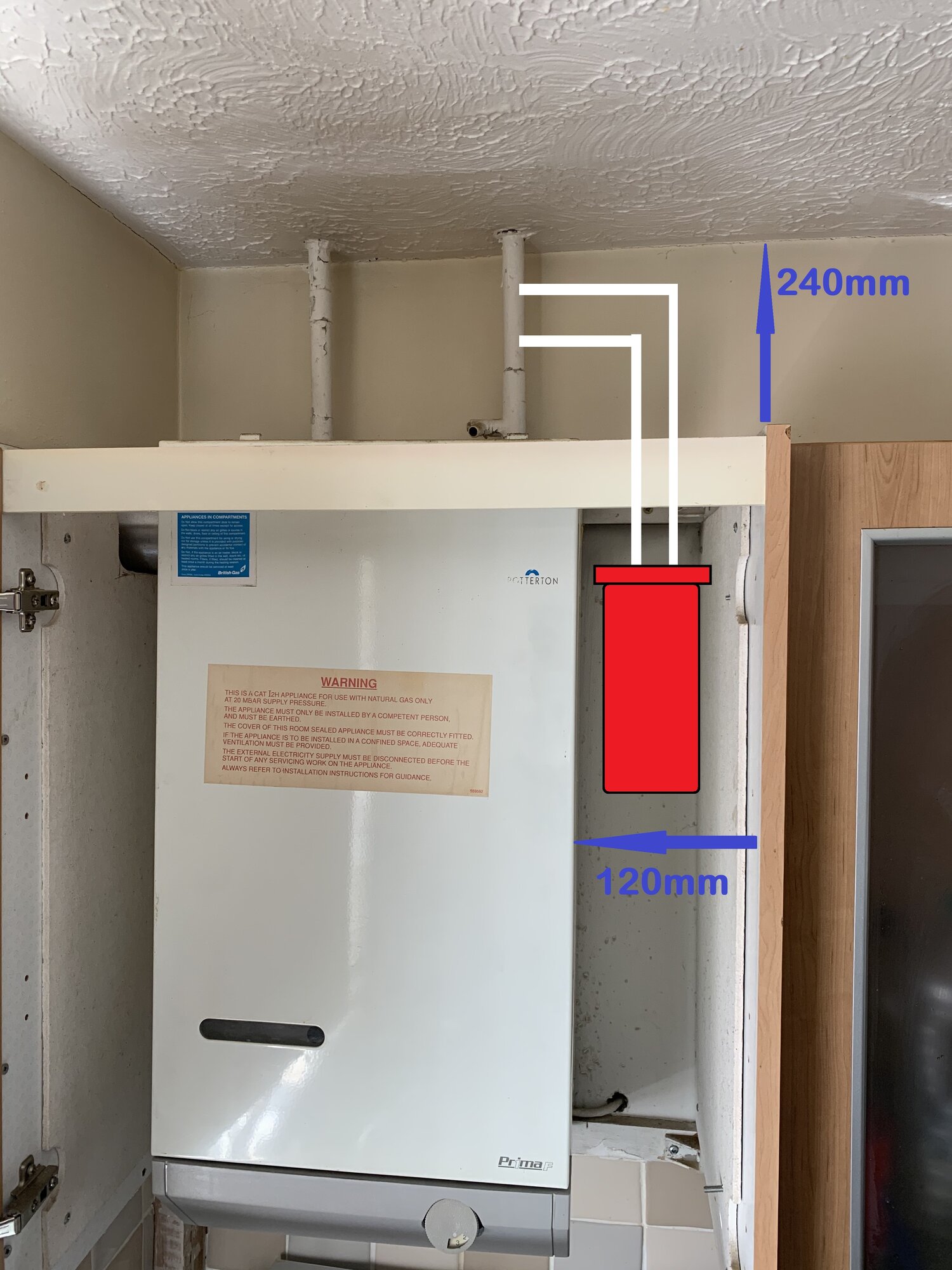

Also while I am at it, Can I fit a Magnaclean filter on a section of visible pipework from the Motorised valve ?. I think space under pump might be good enough.

Looking for a drop in replacement is showing a few different units with a very wide price range. Please which would be ideal one to go for ?. A pic below if it helps.

Also while I am at it, Can I fit a Magnaclean filter on a section of visible pipework from the Motorised valve ?. I think space under pump might be good enough.