Many thanks for all the responses received, I've made a few changes accordingly.

[Norcon: The connection between the stove and uv cylinder is a no no]

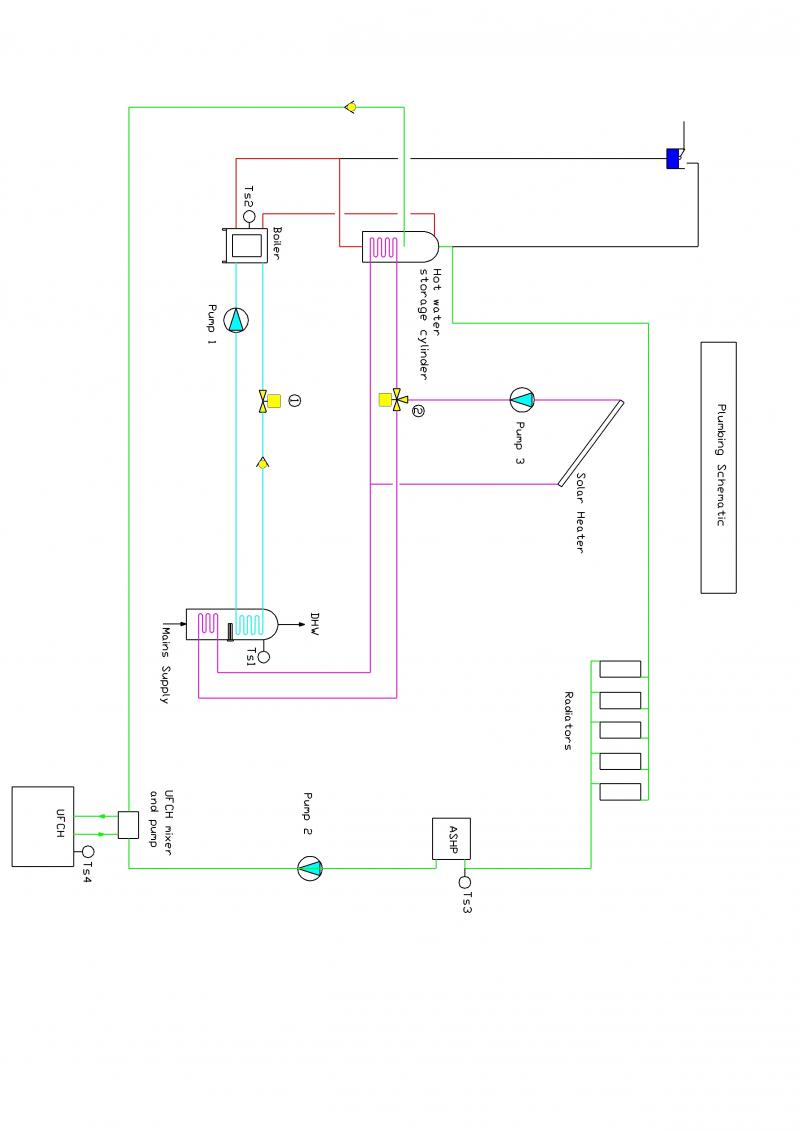

OK, I can provide a separate pumped circuit from the heat store. This will mean the WBS will dissipate heat only by convection, will this be OK?

[Norcon: I would strongly recommend cad design for plumbing and electrics]

What I've done is to simulate all the conditions with the actual valves and thermostats on my kitchen table. I connected them according to the Honeywell sundial wiring diagrams which I found on the net, they are very informative. I powered everything up (very carefully) to make sure the valves were opening and closing at the right settings.

[Onetap: Strange; have you employed someone to design this for you?]

No, onetap, can't afford that. I did it myself, I've learned a bit of AutoCad in my employment.

[Onetap: The UFH will only work when the radiators are on. You'd usually want the UFH to be able to run when the rads are off]

Good point, I've made a change and will fit a three-way valve before the rads. This can bypass them and direct water around the heat pump and uf heating when the storage cylinder water is less than say 60C. Above that the valve will direct hot water as originally piped. I'll have two of the bathroom rads with no TRVs just to be safe

[Onetap: There will be no circulation between the thermal store and DHW cylinder without a pump, unless the solar pump is supposed to do that; circulating hot water through the solar panels on dark winter nights is not a good idea.]

I hadn't planned for circulation between the thermal store and DHW cylinder. The solar circuit is intended to pump as priority (with its own pump) to the DHW cylinder, at which time the loop into the thermal store will be effectively a dead leg. When the DHW temp reaches 60C, the solar flow will change over to the thermal store and there will be no flow through the DHW coil. There is a cut out on the solar unit to prevent it pumping when it is not developing heat.

[Gayton Tonner: He is better off using a thermal store in this application]

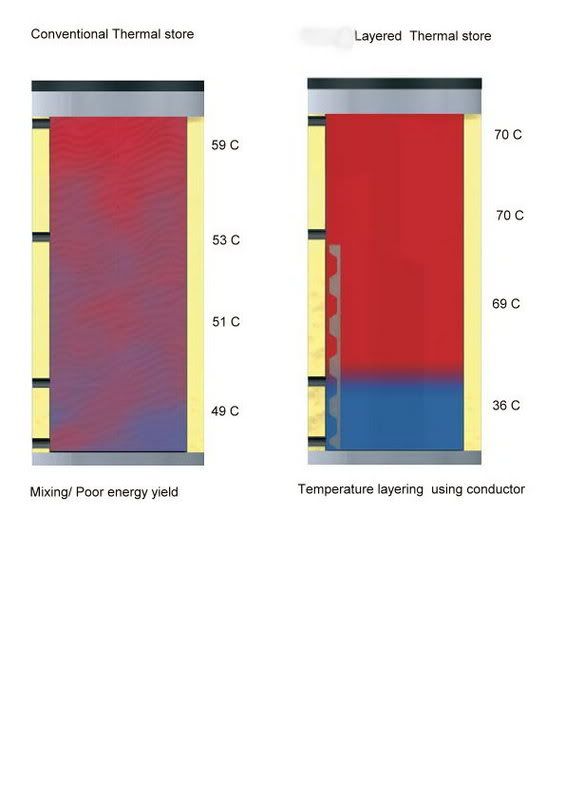

I'm a little confused by this. I thought that my vented 213L storage cylinder with all my input and output connections would actually be a thermal store (sort of).