Haha, slightly concerned about the outcome when I re-fill now! Fingers crossed. Thanks for the replies.

Managed to get the bypass tube in. No matter how hard i pushed from the top down, and shook the pipe when in situ I couldn't get it in, so undid the four screws again on the plastic manifold and dislodged the diverter again. With the LHS pulled out slightly, and a bit of firm wiggling the pipe popped down enough for the clip to be pushed across. I then had to firmly apply some pressure to the diverter from the left to the right to get it back in, as the connected bypass valve had pushed the whole assembly to the left, so the circular part of the plastic manifold overlapped a mm or so with the casing where it pushes into the casing.

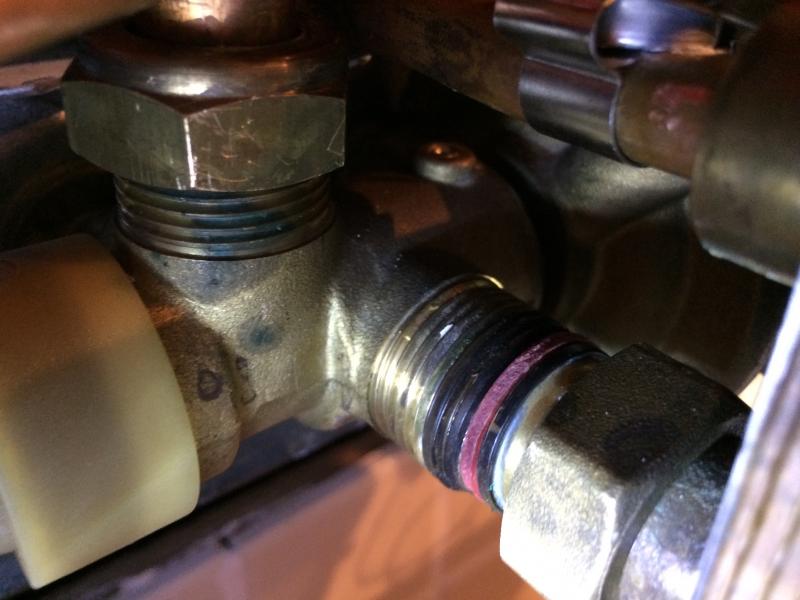

Back in now, just struggling to line up the LHS union connection on the heat exchanger, it's obviously not quite square, so having fun keeping the washer in-line and trying to get the nut to take at the same time!

I have used a 3/4 inch fibre washer from B&Q as the one supplied had snapped, which seems slightly smaller, it's certainly narrower, so hoping that's going to be ok.

Managed to get the bypass tube in. No matter how hard i pushed from the top down, and shook the pipe when in situ I couldn't get it in, so undid the four screws again on the plastic manifold and dislodged the diverter again. With the LHS pulled out slightly, and a bit of firm wiggling the pipe popped down enough for the clip to be pushed across. I then had to firmly apply some pressure to the diverter from the left to the right to get it back in, as the connected bypass valve had pushed the whole assembly to the left, so the circular part of the plastic manifold overlapped a mm or so with the casing where it pushes into the casing.

Back in now, just struggling to line up the LHS union connection on the heat exchanger, it's obviously not quite square, so having fun keeping the washer in-line and trying to get the nut to take at the same time!

I have used a 3/4 inch fibre washer from B&Q as the one supplied had snapped, which seems slightly smaller, it's certainly narrower, so hoping that's going to be ok.