You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Work surface trim.......Help!

- Thread starter Solange

- Start date

D

Deleted member 174758

If not, and the trim is heavy duty laminate, it will need to be cut to size then stuck on with contact adhesive and finally trimmed with s flat, single cut file

D

Deleted member 174758

You simply cannot cut hard laminate with a pair of scissors, let alone trim it. Does the trim you have been supplied with have a brown or black rear side? Is the top surface of the edging strip the same pattern as the worktop surface?

By flat, single cut file I mean just that - a metalworking file about 8 to 10 inches (200 to 250mm) long, flat (as opposed to half round, rat tail, triangular or square shape) with single cut teeth (teeth running diagonally across the body in one direction only,not criss crossed). It needs a handle fitted to avoid injury

By flat, single cut file I mean just that - a metalworking file about 8 to 10 inches (200 to 250mm) long, flat (as opposed to half round, rat tail, triangular or square shape) with single cut teeth (teeth running diagonally across the body in one direction only,not criss crossed). It needs a handle fitted to avoid injury

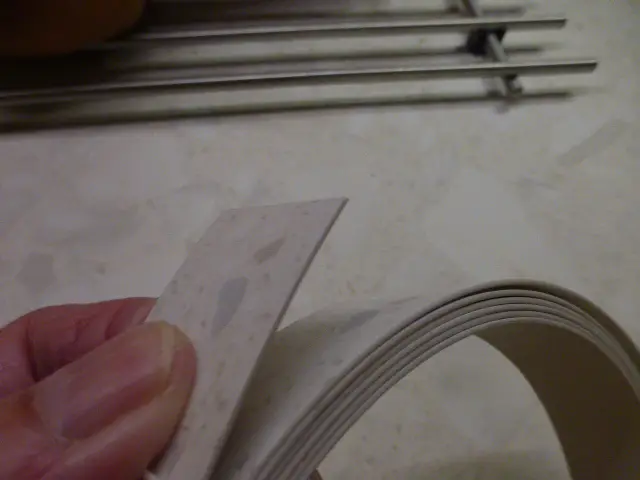

Thanks for advice JobAndKnock. I did cut it to length with a pair of sharp scissors. It has a beige underside as you can see. It was quite easy to cut to length. Never having used a metal working file I'm a bit dubious about using one. Thanks very much for your advice though. Much appreciated. I am going to get some proper adhesive tomorrow.....and.......stick it on!

It should be cut oversized and sanded flush after glueing .

D

Deleted member 174758

The cut (chipboard) edge of the worktop may require two coats before applying the laminate because it is very absorbent - the first coat normally just seals the chipboard but won't give you much "sticking power". Note that with contact adhesive you need to coat both surfaces and leave them to dry for 10 to 15 minutes before joining them. This requires a bit of care and patience. Start from the back edge leaving a bit of an overhang on both edges

Thanks JobAndKnock......I didn't even consider how absorbent it might be but yes, I can see that the area looks quite porous. I might have a bit of care and patience! (I've got a bag of it in my toolbox). Start-from-back-edge-and-leave-a-bit-of-an-overhang-on-both-edges......that's today's mantra! I'll be singing it by this evening. But first this does involve a 22 mile round trip to get the adhesive. Sod's law......

Thanks for your help.

Thanks for your help.

D

Deleted member 174758

Another tip. You can use a small offcut of laminate as a glue spreader.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 10

- Views

- 959