Hoping to open up a technical discussion regarding best practice with Y-strainers (also spelled wye – strainer) on domestic CH systems.

I’m hoping this thread can be a general discussion to explore this topic & share any insights members might have. I’d like to flesh this out - so newbies can enlighten themselves too.

(Assume the Y-strainer is fitted in addition to a mag CH system filter).

Stating the obvious - Two types of debris in CH water - magnetic & non-mag.

Magnetic system filters generally deal with the mag debris VERY well e.g magnaclean, spirovent etc. However - this is not always the case for non-magnetic particles

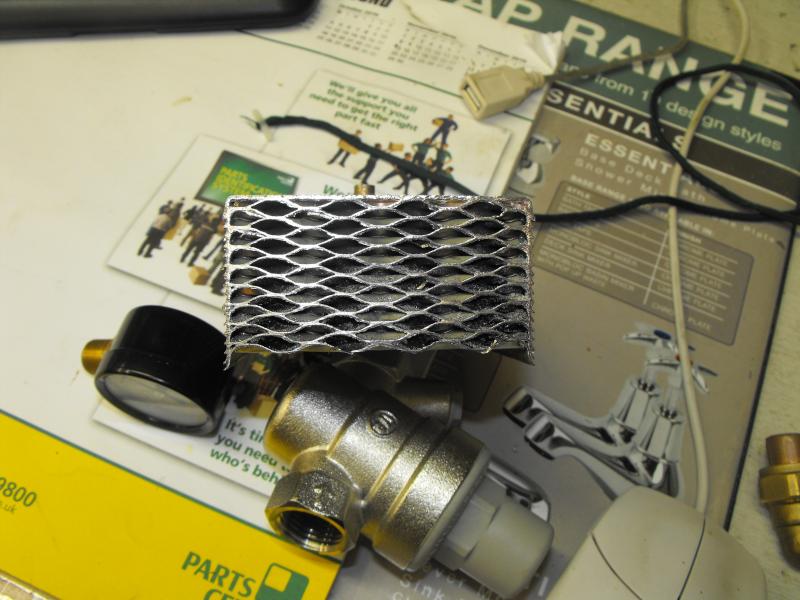

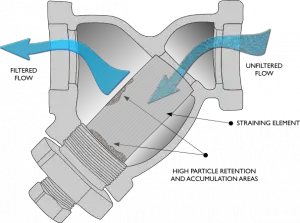

This is where Y-strainers can help. Essentially it's a sieve that collects muck - using a simple stainless steel gauze. They can be placed inline on both the, coldwater fill and/or CH return loop:

----------

----------

Credits: i) Choosing the Right Straining Element, Part One - The Pipeline Flow

ii) Caleffi Hydronic Solutions

Important:

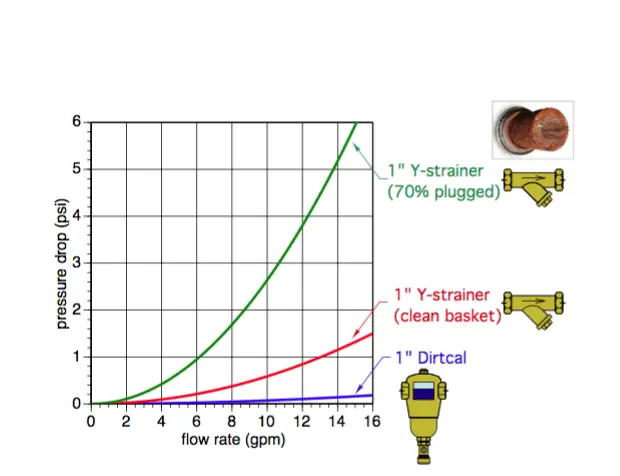

1) They cause a pressure drop in the loop - so step up one/two sizes to increase the surface area of the gauze.

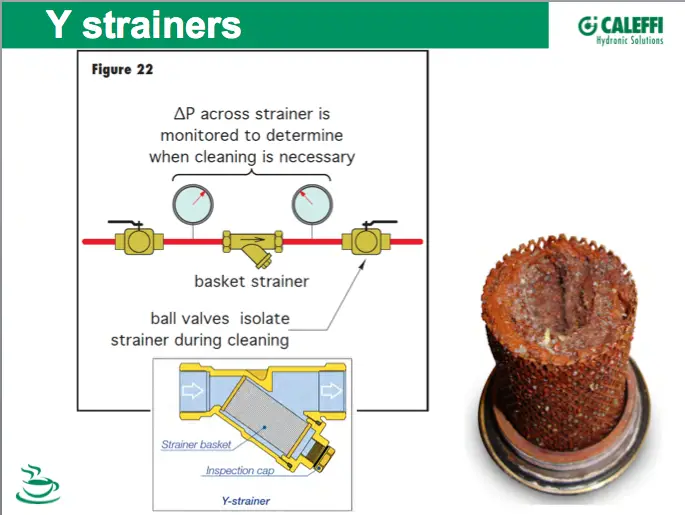

2) They need to be isolated - before & after the valve - so that the gauze can be extracted & cleaned (frequency depends on how dirty the water is).

3) The only real way, to be able to see when it’s blocked – is to have pressure gauges installed inline too - to assess the change in pressure across the gauze/strainer.

Any contributions regarding the basic primer above, is most welcome.

More technical questions for expert members:

A) Gauze/strainer hole size - What is the best correct size to aim for. I've seen y-strainers with gauze as fine as 50 microns available for domestic CH.

B) Are there any strainers that are designed for upward flows - instead of just the horizontal or downward flow ones you can get from toolstation etc.

C) If the gauze does get blocked - do most boilers have a safety mechanism that will simply shut down the pump until the blockage is resolved? I.E should the strainer/gauze get blocked - will it cause irreparable damage to the boiler?

My sincere thanks to anyone willing to contribute to the discussion.

Disclaimer: Yes – in a properly cleaned system that is well installed/maintained – a Y-strainer should not be necessary. However – it is still a good insurance policy – given that they are so cheap. E.g My Ecotec 837 – does not have an inbuilt strainer fitted before the heat exchange. On very rare occasions - it has been known for debris from street level repair works – to work its way into household water supplies. So – This discussion is to focus on those scenarios where a Y-strainer is actually worthwhile – or is at least a sensible precaution – or even as an additional filter.

I’m hoping this thread can be a general discussion to explore this topic & share any insights members might have. I’d like to flesh this out - so newbies can enlighten themselves too.

(Assume the Y-strainer is fitted in addition to a mag CH system filter).

Stating the obvious - Two types of debris in CH water - magnetic & non-mag.

Magnetic system filters generally deal with the mag debris VERY well e.g magnaclean, spirovent etc. However - this is not always the case for non-magnetic particles

This is where Y-strainers can help. Essentially it's a sieve that collects muck - using a simple stainless steel gauze. They can be placed inline on both the, coldwater fill and/or CH return loop:

----------

----------

Credits: i) Choosing the Right Straining Element, Part One - The Pipeline Flow

ii) Caleffi Hydronic Solutions

Important:

1) They cause a pressure drop in the loop - so step up one/two sizes to increase the surface area of the gauze.

2) They need to be isolated - before & after the valve - so that the gauze can be extracted & cleaned (frequency depends on how dirty the water is).

3) The only real way, to be able to see when it’s blocked – is to have pressure gauges installed inline too - to assess the change in pressure across the gauze/strainer.

Any contributions regarding the basic primer above, is most welcome.

More technical questions for expert members:

A) Gauze/strainer hole size - What is the best correct size to aim for. I've seen y-strainers with gauze as fine as 50 microns available for domestic CH.

B) Are there any strainers that are designed for upward flows - instead of just the horizontal or downward flow ones you can get from toolstation etc.

C) If the gauze does get blocked - do most boilers have a safety mechanism that will simply shut down the pump until the blockage is resolved? I.E should the strainer/gauze get blocked - will it cause irreparable damage to the boiler?

My sincere thanks to anyone willing to contribute to the discussion.

Disclaimer: Yes – in a properly cleaned system that is well installed/maintained – a Y-strainer should not be necessary. However – it is still a good insurance policy – given that they are so cheap. E.g My Ecotec 837 – does not have an inbuilt strainer fitted before the heat exchange. On very rare occasions - it has been known for debris from street level repair works – to work its way into household water supplies. So – This discussion is to focus on those scenarios where a Y-strainer is actually worthwhile – or is at least a sensible precaution – or even as an additional filter.