D

Doctor Drivel

Dan_Robinson said:As DD has realised, it is the engineering simplicity (in the case of the Intergas) and sheer performance (in the case of the Multi 24/80+) that keep me installing their boilers above all others. the Multi is pride of place in my office - as has been shown here. In fact DD, I would be interested on yiour thoughts of the Multi?

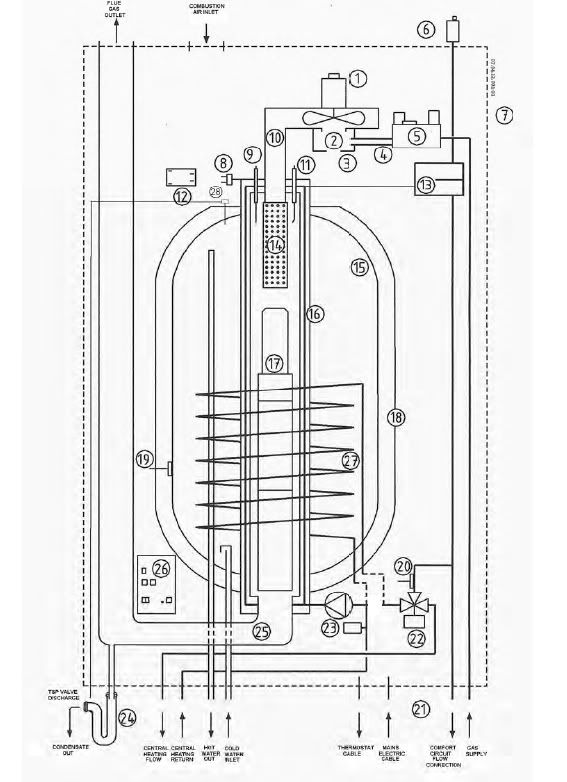

The multi has shades of the ACV HeatMaster - from Belgium, so maybe a Low countries approach, although the Range Powermax was like this.

The Multi plus is excellent no doubt. The DHW booster coil must be an added advantage in efficiency producing lower return temperatures and higher flowrates.

Good points

- looks like the primary heat exchanger can run at a very large temperature differentials. Most condensing boiler makers state 20C Delta T (temp differential between flow and return). This looks like it can be very wide indeed extracting as much heat as possible from the flue gases.

- CH and DHW can be run at he same time, although not a big problem when DHW only in other setups.

- High flowrates - although I'm not sure how long it will last and then run out of hot water. Does it drop to lower flowrates when the cylinder is exhausted of hot water?

- The bathroom rad comfort circuit. A nice touch. Maybe this can be used (adapted) for CH zoning.

- The HepVo trap on the unvented blow-off and combining the condensate and blow-off into one trap.

Iffy Points

- Uses an unvented cylinder.

- No catering for TVRs all around.

I like integrated thermal storage using this flue through cylinder approach. The ACV does this although uses a tank-in-tank unvented cylinder for DHW. However the CH come off the outer primary water thermal store. This means a Grundfos Alpha smart pump with TRVs all around can be used with no nuisance central room stat or efficiency lowering auto by-passes used. It seems the Multi needs a central room stat and cannot use a smart pump. Few boilers cater for TRVs all around which is now the norm.

The Atmos Multi has been around for while now and needs an update catering for TVRs all around. Since 1994, plate heat exchangers have improved no end and smart pumps have arrived. What must be catered for:

1. TRVs all around

2. Two CH zones, which half does. This would set this boiler on a higher level.

I think the ACV is the only integrated thermal storage unit around (well a thermal store/unvented cylinder hybrid), as the Range Powermax is now using an unvented cylinder.

A quality product no doubt. For the price I would also consider an ACV HeatMaster. Gledhill are a level down in quality.