You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

central heating only comes on with h water, stumped engineer

- Thread starter bonkersbill

- Start date

Thinking logically, to prove if the CH return is piped into the flow (as per 4expaw's earlier post) or totally blocked somewhere, you could:

1) Obtain a pair of clip-on pipe thermometers (or a IR thermometer), leave the radiators to cool and make sure all radiator valves are fully open.

2) Manually set the 3PV to HW only, turn on the boiler and measure the temperature of the HW tank flow pipe and the pipe entering the pump. Make a note of the difference between the two (they should be almost identical)

3) After a few minutes when the above temp has stabilised, manually turn the 3PV to CH&HW whilst you are still measuring the pipe temperatures.

If the difference between the pump and HW flow pipe temperature increases when you turn the 3PV to CH&HW, then it's highly likely the CH return is piped incorrectly into the boiler flow or blocked somewhere along the route. (ie. The temperature would lower if/when the cold(er) water from the CH return flows back through port A & diluting with the flow lowering the overall temp being measured at the tank flow pipe.)

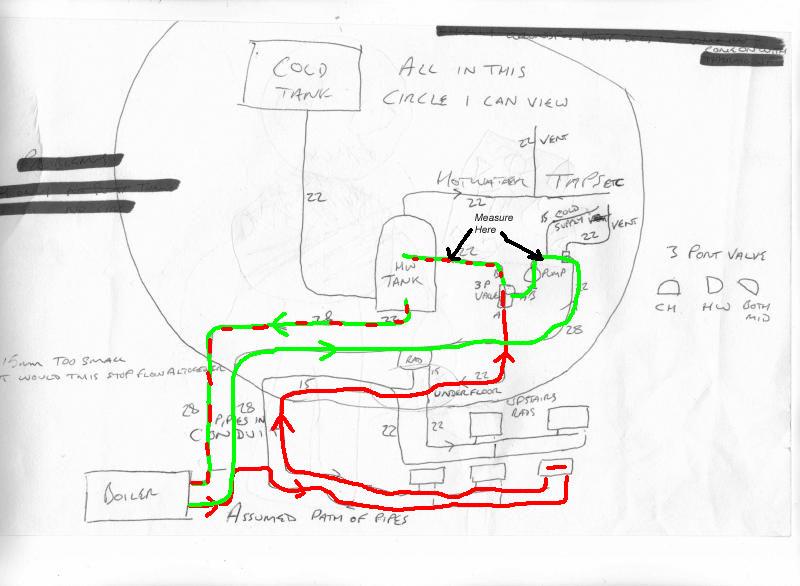

To make it clearer, here's what maybe happening and assumes the 3PV is in the CH&HW position.

The RED route is how the radiators could be heating (Ive just included one for ease) and the GREEN route how the HW is being heated.

P.s. The thermometer(s) will cost around £10 and can be used afterwards to balance all your radiators when this issue is fixed!

1) Obtain a pair of clip-on pipe thermometers (or a IR thermometer), leave the radiators to cool and make sure all radiator valves are fully open.

2) Manually set the 3PV to HW only, turn on the boiler and measure the temperature of the HW tank flow pipe and the pipe entering the pump. Make a note of the difference between the two (they should be almost identical)

3) After a few minutes when the above temp has stabilised, manually turn the 3PV to CH&HW whilst you are still measuring the pipe temperatures.

If the difference between the pump and HW flow pipe temperature increases when you turn the 3PV to CH&HW, then it's highly likely the CH return is piped incorrectly into the boiler flow or blocked somewhere along the route. (ie. The temperature would lower if/when the cold(er) water from the CH return flows back through port A & diluting with the flow lowering the overall temp being measured at the tank flow pipe.)

To make it clearer, here's what maybe happening and assumes the 3PV is in the CH&HW position.

The RED route is how the radiators could be heating (Ive just included one for ease) and the GREEN route how the HW is being heated.

P.s. The thermometer(s) will cost around £10 and can be used afterwards to balance all your radiators when this issue is fixed!

Thinking logically the htg return is show connected to the boiler return, just the boiler is upside down, I would imagine it's indicative as the OP doesn't know.

In any case all the radiators work, now can there be a blockage.

What is blocking the circulation in the htg mode.

Why doesn't the boiler stat turn off in the HTG only mode.

This is a gravity boiler and would happily cut in and out on the stat all day long whether there was circulation or not.

In any case all the radiators work, now can there be a blockage.

What is blocking the circulation in the htg mode.

Why doesn't the boiler stat turn off in the HTG only mode.

This is a gravity boiler and would happily cut in and out on the stat all day long whether there was circulation or not.

I just had another line of thought, one never knows what happens when one who does not fully well understand the function of things in general, can end up using them incorrectly, or for those who might have a go at things, thinking they are well knowledged about it, but gets it wrong. we know we all love doing things but certain things are best left to the professionals.

i am not digging at anyone, its just my way of being polite, and life long experience in some of the things I have seen how badly they are done.

Now my new line of thought says, that the 3 way diverter valve could have been installed incorrectly, where it has an in coming hot water port directly from the boiler via a pump, and two outgoing ports, one to CH circuit and the other to Hot water tank, if you think about it, if someone who carried out this installation years ago did not quite know and managed to connect pipes incorrectly, whereby the in coming hot water feed was actually connected to one of the out going porrts! and now you can imagine what is going to happen.......exactly! you get it, it would function exactly as the symptoms you have described, i.e. in both CH+HW it would function OK, the boiler won't cut off through overheat, because the circulation is in both direction, and if you only had your HW on, even then the system is fine as the flow is occuring between the hot water feed from the boiler and the HW cylinder

But now if you turned the switch to CH mode only, the flow from the boiler cannot flow out to any of the circuits, neither to CH nor to HW cylinder and the it takes around 20 to 30 seconds for the water to overheat and cut off the boiler.

I can safely assume someone has connected the 3 port valve incorrectly, now that you have determined your flow is fine as you have managed to get all your rads red hot! Time to trace exactly the hot water flow pipe from the boiler to this diverter valve and make sure it is plumbed into the in coming port, usually in the middle, as the middle part of a T

good luck and I hope this was the problem that you had been having for over 2 yaesr and normally most engineers wouldn't think someone would have carried out an installation that wrong! hence why they haven't managed to find a fault in that short time they have allocated for your job, and as I said earlier, they are inundated with work load and have to be at another job or they could loose out on some of their customers if they did not turn up especially during freezing weaather.

To most engineers they would start looking at MVs and things like that for faults and obviously when they do not find anything wrong with MVs they do not suspect that someone may have carried out an installation incorrectly, so they are likely to leave and say they can't find anything wrong rather than spend a whole day trying to sort out someone's incorrect plumbing, and loose may be 5 other customers!

But guys, don't just panic! my above diagnostics is based on an asumption, which is a path one must consider if it comes to fault finding!

i am not digging at anyone, its just my way of being polite, and life long experience in some of the things I have seen how badly they are done.

Now my new line of thought says, that the 3 way diverter valve could have been installed incorrectly, where it has an in coming hot water port directly from the boiler via a pump, and two outgoing ports, one to CH circuit and the other to Hot water tank, if you think about it, if someone who carried out this installation years ago did not quite know and managed to connect pipes incorrectly, whereby the in coming hot water feed was actually connected to one of the out going porrts! and now you can imagine what is going to happen.......exactly! you get it, it would function exactly as the symptoms you have described, i.e. in both CH+HW it would function OK, the boiler won't cut off through overheat, because the circulation is in both direction, and if you only had your HW on, even then the system is fine as the flow is occuring between the hot water feed from the boiler and the HW cylinder

But now if you turned the switch to CH mode only, the flow from the boiler cannot flow out to any of the circuits, neither to CH nor to HW cylinder and the it takes around 20 to 30 seconds for the water to overheat and cut off the boiler.

I can safely assume someone has connected the 3 port valve incorrectly, now that you have determined your flow is fine as you have managed to get all your rads red hot! Time to trace exactly the hot water flow pipe from the boiler to this diverter valve and make sure it is plumbed into the in coming port, usually in the middle, as the middle part of a T

good luck and I hope this was the problem that you had been having for over 2 yaesr and normally most engineers wouldn't think someone would have carried out an installation that wrong! hence why they haven't managed to find a fault in that short time they have allocated for your job, and as I said earlier, they are inundated with work load and have to be at another job or they could loose out on some of their customers if they did not turn up especially during freezing weaather.

To most engineers they would start looking at MVs and things like that for faults and obviously when they do not find anything wrong with MVs they do not suspect that someone may have carried out an installation incorrectly, so they are likely to leave and say they can't find anything wrong rather than spend a whole day trying to sort out someone's incorrect plumbing, and loose may be 5 other customers!

But guys, don't just panic! my above diagnostics is based on an asumption, which is a path one must consider if it comes to fault finding!

Obviously I cannot rule out yet another unlikely possibility, a 3 way valve internals could be assembled wrongly whereby it will open in two settings and fail to open in a 3rd, i can explain thi9s using diagrams, but just don't have enough time to do it and post explainations, so if you think the diverter valve is correctly plumbed, i.e. the incoming port is connected correctly to the boiler's output via the pump, then look into this valve, can you blow through the middle port to one port only and and then to the other port and in the mid position through both ports, so check that as well.

And because its a gravity filled or fed system, which uses water tanks in the loft, often they can get debri fall into them or rats mic and other things can make home into these tanks, and they can enter the pipe work and cause blockage in ports and so on.

And because its a gravity filled or fed system, which uses water tanks in the loft, often they can get debri fall into them or rats mic and other things can make home into these tanks, and they can enter the pipe work and cause blockage in ports and so on.

I just had another line of thought, one never knows what happens when one who does not fully well understand the function of things in general, can end up using them

Mike, one of the reasons this thread is now 12 pages long is several posters are asking the same questions that were discussed and answered in earlier posts.

I can safely assume someone has connected the 3 port valve incorrectly, now that you have determined your flow is fine as you have managed to get all your rads red hot! Time to trace exactly the hot water flow pipe from the boiler to this diverter valve and make sure it is plumbed into the in coming port, usually in the middle, as the middle part

This is a typical example (It's already been discussed, replaced new and if you were to look at the pictures, already know the answer so wouldn't have asked this question...again!)

Obviously I cannot rule out yet another unlikely possibility, a 3 way valve internals could be assembled wrongly whereby it will open in two settings and fail to open in a 3rd

You think TWO 3 way valves have been assembled wrongly? (original and replacement?)

The op needs some help in identifing the cause & ways of prooving or discounting suggestions/theories in order to identify and resolve the issue. Perhaps after reading the thread you could provide some tests/solutions to help?

- Joined

- 28 May 2010

- Messages

- 110

- Reaction score

- 0

- Country

i have started the boiler with Prog set CH & HW with 3pv in mid position, turned of HW at Prog, boiler stayed going for 3 or 4 mins before shutting off.

CH&HW on and in mid pos with boiler turn up to full heat, then turn 3pv to CH, boiler boils and bangs, the vent i could feel rattleing but nothing came out to the header, having said that, the top of the header was wet when i got up there so perhaps the previous test it did blow into the header.

i will buy a couple of these temp gauges tommorrow presumably from a plumbers merchant and will run the test for temp and check which pipes get hot 1st that connect to the HW tank.

4expaws i have only just got round to looking at your post, one of my pictures shows the pipework under the floor, this is about 3 feet from the top of the conduit and there are no tees into the 28mm pipes above the conduit from under the floor, unfortunatly i have a built in wardrobe above so i cant see down the boxing, i will cut out the conduit at the side of the boiler which i think i will have to do thursday now. the ground floor is raised and if need be i will lift the carpet to see whats below the floor. you said that i had said the pipe below the 3pv was not hot, this may have been the case on one of the tests but it does get red hot when the valve opens to let water through. i will run through the rest of your suggestions when i have better access and have run the other tests above

CH&HW on and in mid pos with boiler turn up to full heat, then turn 3pv to CH, boiler boils and bangs, the vent i could feel rattleing but nothing came out to the header, having said that, the top of the header was wet when i got up there so perhaps the previous test it did blow into the header.

i will buy a couple of these temp gauges tommorrow presumably from a plumbers merchant and will run the test for temp and check which pipes get hot 1st that connect to the HW tank.

4expaws i have only just got round to looking at your post, one of my pictures shows the pipework under the floor, this is about 3 feet from the top of the conduit and there are no tees into the 28mm pipes above the conduit from under the floor, unfortunatly i have a built in wardrobe above so i cant see down the boxing, i will cut out the conduit at the side of the boiler which i think i will have to do thursday now. the ground floor is raised and if need be i will lift the carpet to see whats below the floor. you said that i had said the pipe below the 3pv was not hot, this may have been the case on one of the tests but it does get red hot when the valve opens to let water through. i will run through the rest of your suggestions when i have better access and have run the other tests above

- Joined

- 28 May 2010

- Messages

- 110

- Reaction score

- 0

- Country

The 3pv has been replaced and i have checked the hot water from the boiler is going to the middle of the 3pv, it was a while ago so i will recheck to make sure, i have replaced all the loft tanks with new ones so no debris, though this post maybe long i am greatful for the suggestions and understand that because of its length some of you wont want to read it all, the problem is we have not found what the cause of the boiler turning off is yet but i feel we are getting close with the barrage of recent tests, let me carry out the latest set and get a better view of some hidden pipes and lets take it from there.

Thanks to everyone who is giving input

Thanks to everyone who is giving input

p="2316940"]

The op needs some help in identifing the cause & ways of prooving or discounting suggestions/theories in order to identify and resolve the issue. Perhaps after reading the thread you could provide some tests/solutions to help?

I don't know if your comments actually will help Op to narrow down the fault or mine, but still without me reading all 10 posts or so, I am convinced this is his problem, has he physically taken his 3 way valve out of the system and blown through it to make sure that all ports are doing what they are suppose to do, and has he with 100% guaranteed traced that the pipe that feds the inlet port is the one that is coming from the boiler via the pump?

Or is it just another assumed possibility that things couldn't have been carried out wrong in the first place. or in otherwords taking things for guaranteed, well i never dotake things for guarantee and always check individual item's function. I don't assume things in this instance.I have to be 200% certain.

May be a good idea for op to get hold of his old valve and take a good look at it how it functions and any possibility of it being installed wrongly. thats for op to check.

i will buy a couple of these temp gauges tommorrow presumably from a plumbers merchant and will run the test for temp and check which pipes get hot 1st that connect to the HW tank.

They are £6.60 each from here as a guide for the clip on type or you could use a IR thermostat (I brought one like this which works okay on pipes when used with black tape and I have found lots of other uses for it from cooking to balancing radiators!

Mike has made some good points, which goes with some questions I have.

Originally the boiler was gravity primaries, what happened to the htg connect at the boiler ??

To add to Mikes post, supposing he was closer than he thinks, and the pump and MV are actually on the return sucking out of the boiler.

Bills drawing actually shows something like that but it may have been indicative and not intentional.

Supposing the htg return was then connected to the bottom pipe and the flow from the MV, then the flow and return would be common either side of the pump/MV, and could in affect bypass the boiler.

Originally the boiler was gravity primaries, what happened to the htg connect at the boiler ??

To add to Mikes post, supposing he was closer than he thinks, and the pump and MV are actually on the return sucking out of the boiler.

Bills drawing actually shows something like that but it may have been indicative and not intentional.

Supposing the htg return was then connected to the bottom pipe and the flow from the MV, then the flow and return would be common either side of the pump/MV, and could in affect bypass the boiler.

Mike has made some good points, which goes with some questions I have.

Originally the boiler was gravity primaries, what happened to the htg connect at the boiler ??

To add to Mikes post, supposing he was closer than he thinks, and the pump and MV are actually on the return sucking out of the boiler.

Bills drawing actually shows something like that but it may have been indicative and not intentional.

Supposing the htg return was then connected to the bottom pipe and the flow from the MV, then the flow and return would be common either side of the pump/MV, and could in affect bypass the boiler.

Thanks Doitall, I read as many earlier posts on this thread as I could, and then I turned to last few posts on pages 9 and 10, and thought no one has been able to come up with anything yet, so i head butted in to see what i can come up with, and as i said my reasons are based entirely on logic, I am not a professional plumber or a heating expert but have helped many of my friends in sorting out plumbing like leaky valves, malfunctioning MVs and so on, over the past 35 years! yes I am close to 60!

why I recahed my conclusion on the 3 way diverter valve not being connected correctly is self evident, op had tested all his rads and found that the flow was not restrictive as we had all suspected it might be, I had asked him to open all his valves, on both sides of the rad, so he did and he found he could now heat all of his rads when his boiler function was in dual mode i.e. CH+HW.

But as soon as he throws his boiler function in CH mode, it cuts out due to overheat within seconds, indicating a completly dead flow, since we cannot rule that his flow is completely dead as we have just proved that all his radiators heated up when they are in CH+HW mode and also when he throws his boiler in HW mode only, the boiler continuse to function fine, so this only now leaves with one possibility, that is the divereter valve has been plumbed incorrectly.

it is now really a matter for op to double check that his incoming port is definitely connected to the boiler's outflow pipe via the pump, and not just assume it is, or feel it is as he might be sensing it gets hot first from cold, it is only with this logic that he would get a problem like he is getting one for well over 2 years now, and he has said he has had 3 engineers to sort it out.

And as I said if I was the engineer, I would most probably not even think that his diveretr valve has been plumbed wrong and will try and look for a fault elsewhere, as i would assume his problem has arrisen due to malfunction of perhaphs electrical connections somewhere or a malfunctioning MV.

edit: thanks for doing a drawing that would help op, and others to understand the problem better.

View media item 43343

Was thinking along a similar line earlier Mike, when looking at the OP drawing, which is clearly wrong, and wonder whether it was really connected that way.

As you can see from the drawing, if it was like this, there is no heating flow through the boiler.

Was thinking along a similar line earlier Mike, when looking at the OP drawing, which is clearly wrong, and wonder whether it was really connected that way.

As you can see from the drawing, if it was like this, there is no heating flow through the boiler.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 39

- Views

- 4K

C

- Replies

- 3

- Views

- 2K

- Replies

- 1

- Views

- 947

- Replies

- 5

- Views

- 1K