- Joined

- 22 Mar 2014

- Messages

- 9

- Reaction score

- 0

- Country

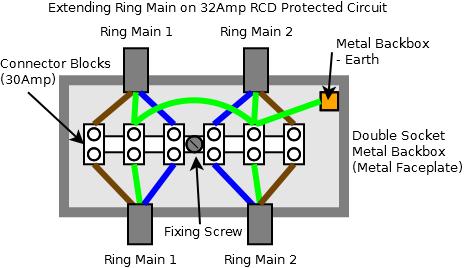

Am looking to extend my ring main by 4 sockets from a socket that is no longer required (at its present location) and wanted to check if the following solution (using materials I have to hand) meets all the required regulations.

I've attached a diagram of a double socket metal back box that I would like to fill with 6 30amp connector blocks. The ring circuit is on a 32amp rcd protected circuit. I will be placing a blanking plate over it.

Would this approach meet regulations and the approval of your helpful sparky selves?

Thanks

I've attached a diagram of a double socket metal back box that I would like to fill with 6 30amp connector blocks. The ring circuit is on a 32amp rcd protected circuit. I will be placing a blanking plate over it.

Would this approach meet regulations and the approval of your helpful sparky selves?

Thanks