Excellent idea! Dare I try it, though?Mike...why not try putting a fixed value or variable resistor in place of the return sensor. You can then model the return temp and see if this has any effect on the firing profile.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reverse boiler flush? (Viessmann Vitodens 100)

- Thread starter MikeAustin

- Start date

- Joined

- 10 Oct 2011

- Messages

- 16,396

- Reaction score

- 4,043

- Country

Why not employ someone who knows what they are doing?

Sorry Mike but you are pizzing in the wind.

Could have been sorted out by now , jeez.

Sorry Mike but you are pizzing in the wind.

Could have been sorted out by now , jeez.

Because the last person to look at the system "who knew what he was doing" said I probably needed a new PCB @ £370, and even quoted for a new boiler. A few pence for a resistor just to check the diagnosis was a brilliant suggestion from HootingOwl.Why not employ someone who knows what they are doing?

Sorry Mike but you are pizzing in the wind.

Could have been sorted out by now , jeez.

- Joined

- 10 Oct 2011

- Messages

- 16,396

- Reaction score

- 4,043

- Country

This thread will go @ least 15 pages with your issue still not sorted out.

It's not rocket science is it? , you have a restriction somewhere.......not worth 7 pages of drivel.

It's not rocket science is it? , you have a restriction somewhere.......not worth 7 pages of drivel.

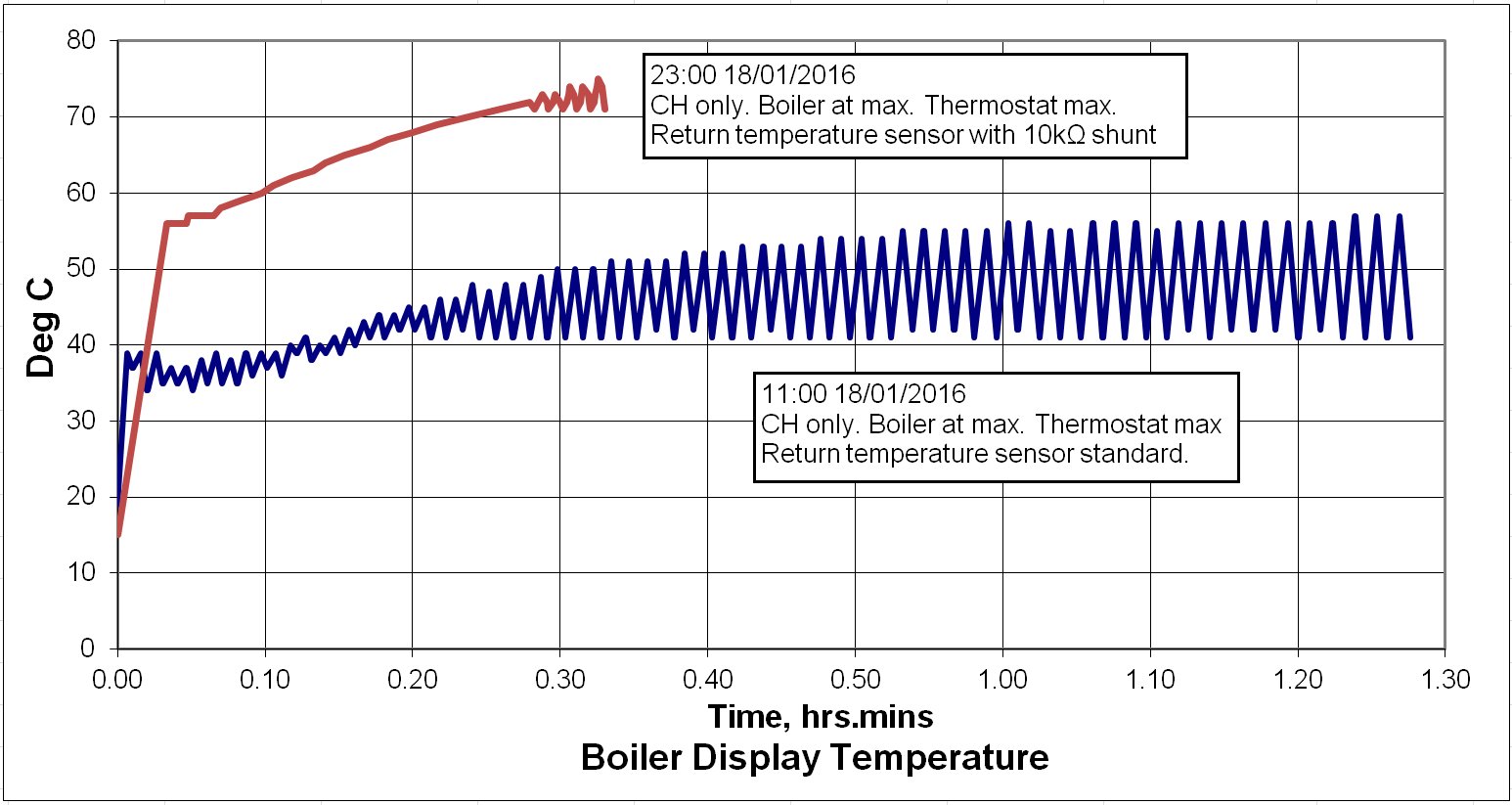

Well, I dared - and the results look fine. I put a 10kΩ shunt across the return temperature sensor. This raises the apparent temperature (seen by the boiler) and allows it to continue burning from the start rather than cycling. My calculations showed that the boiler would think the return was 52C when it was actually 41C. I predicted that the return would reach 72C before the boiler levels off. My measurements have verified this. The boiler was reaching about 60C after nearly 2 hours and staying there. Now it reaches 72C after about 28 minutes and stays there. Here are the results for CH and room stat in the hallway at max:

Turning the room stat to a sensible value of about 17C, the boiler levels off at around 62C.

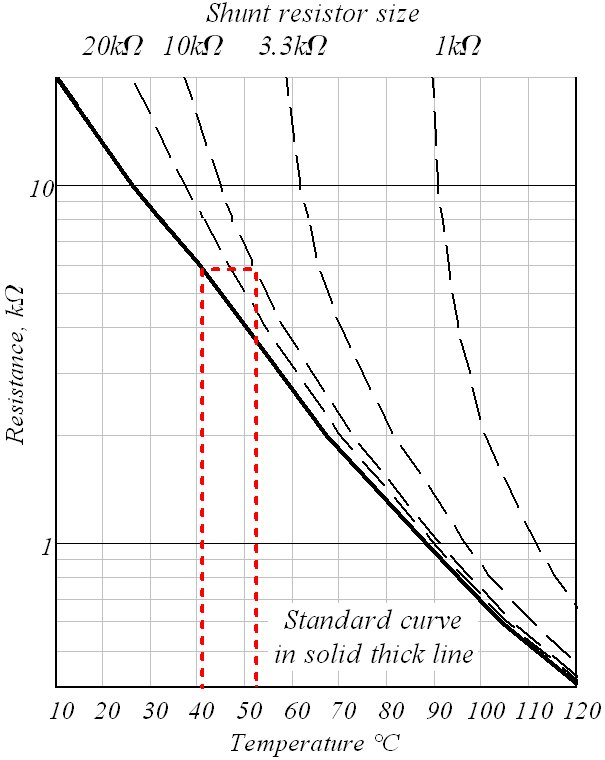

I was originally just going to try a resistor in place of the sensor as a diagnostic, but I realised one could be selected to work in conjunction with the sensor as an eventual solution. The sensor's characteristics from the manual together with the modified curves are here:

To get the temperature the boiler sees from the actual temperature, say 41C, read up to the solid curve, move across to the resistor curve (10kΩ) and read down to 52C. This is quite a difference at low temperatures, but do the same at 70C and the actual is 75C.

My boiler is getting serviced tomorrow, so I will run this by him. I will also contact Viessmann support again to see what comment they have. I am of the opinion that a low return temperature shortly after startup could be due to a restriction or due to long pipework (or a combination) - and the boiler cannot distinguish the two. It only knows temperatures - not flow rates. What I have done only tackles long pipework.

I was originally just going to try a resistor in place of the sensor as a diagnostic, but I realised one could be selected to work in conjunction with the sensor as an eventual solution. The sensor's characteristics from the manual together with the modified curves are here:

My boiler is getting serviced tomorrow, so I will run this by him. I will also contact Viessmann support again to see what comment they have. I am of the opinion that a low return temperature shortly after startup could be due to a restriction or due to long pipework (or a combination) - and the boiler cannot distinguish the two. It only knows temperatures - not flow rates. What I have done only tackles long pipework.

Basically, I follow this link. I use an old laser thermometer that I bought for reflowing solder on circuit boards. It is not suitable for pipework so I cannot measure flow and return temperatures at the boiler. A new one is on order for that. Because my system has long pipework, the lockshields need to be set anywhere between 3/4 turn and 4 turns (i.e. fully) open. That probably indicates quite a lopsided system. What do you think from your experience? Incidentally, have you often encountered domestic systems with the furthest rad 18m from the boiler?What have you done to balance the rads?

No, not yet. To do that properly, I will need my new laser thermometer to get the temperature at their location.Have you measured the actual resistance values of the sensors?

Have you measured the actual resistance values of the sensors?

No, not yet. To do that properly, I will need my new laser thermometer to get the temperature at their location.

I often feel that I am talking a foreign language to you!

Resistance values are measured with a multimeter!

For heating measurements a contact thermocouple probe is needed. A reflective IR meter is of little use.

Tony

I know the feeling!I often feel that I am talking a foreign language to you!

Of course! I have multimeters, but resistance measurements mean little unless related to a temperature that can be compared with the sensors quoted characteristics.Resistance values are measured with a multimeter!

That is interesting to know. I got a dial gauge a couple of weeks ago, but it is totally useless.For heating measurements a contact thermocouple probe is needed. A reflective IR meter is of little use.

Contact "K" type thermocouple is what is needed and they are accurate to at least 0.1 C. Simple temp meters will show two inputs or one and the difference. The VERY cheapest has two inputs but only displays ONE at a time or the difference.

Practically, RGIs measure sensors at room temperature because that what the appliance is usually at if not been working for a while.

So that's at 20 C at which a nominal 10k thermistor is about 13k.

There are only two common faults, O/C and becoming O/C when it gets hot.

They virtually never don't follow their resistance curve.

I did encounter one but that was because water had leaked into the element. That had a very odd "curve".

Tony

Practically, RGIs measure sensors at room temperature because that what the appliance is usually at if not been working for a while.

So that's at 20 C at which a nominal 10k thermistor is about 13k.

There are only two common faults, O/C and becoming O/C when it gets hot.

They virtually never don't follow their resistance curve.

I did encounter one but that was because water had leaked into the element. That had a very odd "curve".

Tony

If anyone is reading this thread with the same problem as the OP then I can report that I fixed one of these boilers today which had the same problem. The primary heat exchangers don't like dirty water and don't like not having pump overrun set up. The hex can get obstructed.

System was powerflushed a few months back with DS40 and it improved significantly.

But it was still taking ages to reach 60 degree and was cutting out after very short burn cycles . So I connected the powerflush directly onto the boiler and poured in 3 litres of fx2, set it to 70 degrees and let it simmer for a few hours. Reversed flow several times.

Neutralised and flushed through. Problem eradicated.

OP - how did you get on?

System was powerflushed a few months back with DS40 and it improved significantly.

But it was still taking ages to reach 60 degree and was cutting out after very short burn cycles . So I connected the powerflush directly onto the boiler and poured in 3 litres of fx2, set it to 70 degrees and let it simmer for a few hours. Reversed flow several times.

Neutralised and flushed through. Problem eradicated.

OP - how did you get on?

Hi HO,If anyone is reading this thread with the same problem as the OP then I can report that I fixed one of these boilers today which had the same problem. The primary heat exchangers don't like dirty water and don't like not having pump overrun set up. The hex can get obstructed.

System was powerflushed a few months back with DS40 and it improved significantly.

But it was still taking ages to reach 60 degree and was cutting out after very short burn cycles . So I connected the powerflush directly onto the boiler and poured in 3 litres of fx2, set it to 70 degrees and let it simmer for a few hours. Reversed flow several times.

Neutralised and flushed through. Problem eradicated.

OP - how did you get on?

I have done nothing more to my system, which is limping along just adequately at the moment. As you may have read in another thread, the flappy valve got stuck and I got someone to remove it. It was quite coked up inside. When it comes round for service, I will put your suggestion to him. The guy is very familiar with these boilers.

The Vitodens heat exchanger likes filling up with debris, we fitted a lot of them and even with a dirt filter and a full powerflush the long spiral heat exchanger can get partially obstructed by the smallest amount of muck.

So I think you are on the right track, however the sarcasm above is noted. Us tradesman have done this type of thing before and we can normally tell a story about when one went wrong. If you are not familiar with heating systems this probably isn't the job to start on.

I posted this on Page 1. We've come a long way.

... except that it was the burner that I was referring to when I said it got coked up. See the picture in the thread here.The Vitodens heat exchanger likes filling up with debris, we fitted a lot of them and even with a dirt filter and a full powerflush the long spiral heat exchanger can get partially obstructed by the smallest amount of muck.

So I think you are on the right track, however the sarcasm above is noted. Us tradesman have done this type of thing before and we can normally tell a story about when one went wrong. If you are not familiar with heating systems this probably isn't the job to start on.

I posted this on Page 1. We've come a long way.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 0

- Views

- 2K

- Replies

- 3

- Views

- 1K

- Replies

- 1

- Views

- 1K