Hi all, hoping I can gain from your wealth of experience. We're getting the whole house rendered at some point reasonably soon and I'd like to sort out the mish-mash of pipework on the back wall while we're at it. Access to underfloor space is possible but its a bugger to get into so would rather keep as much work on the outside as possible.

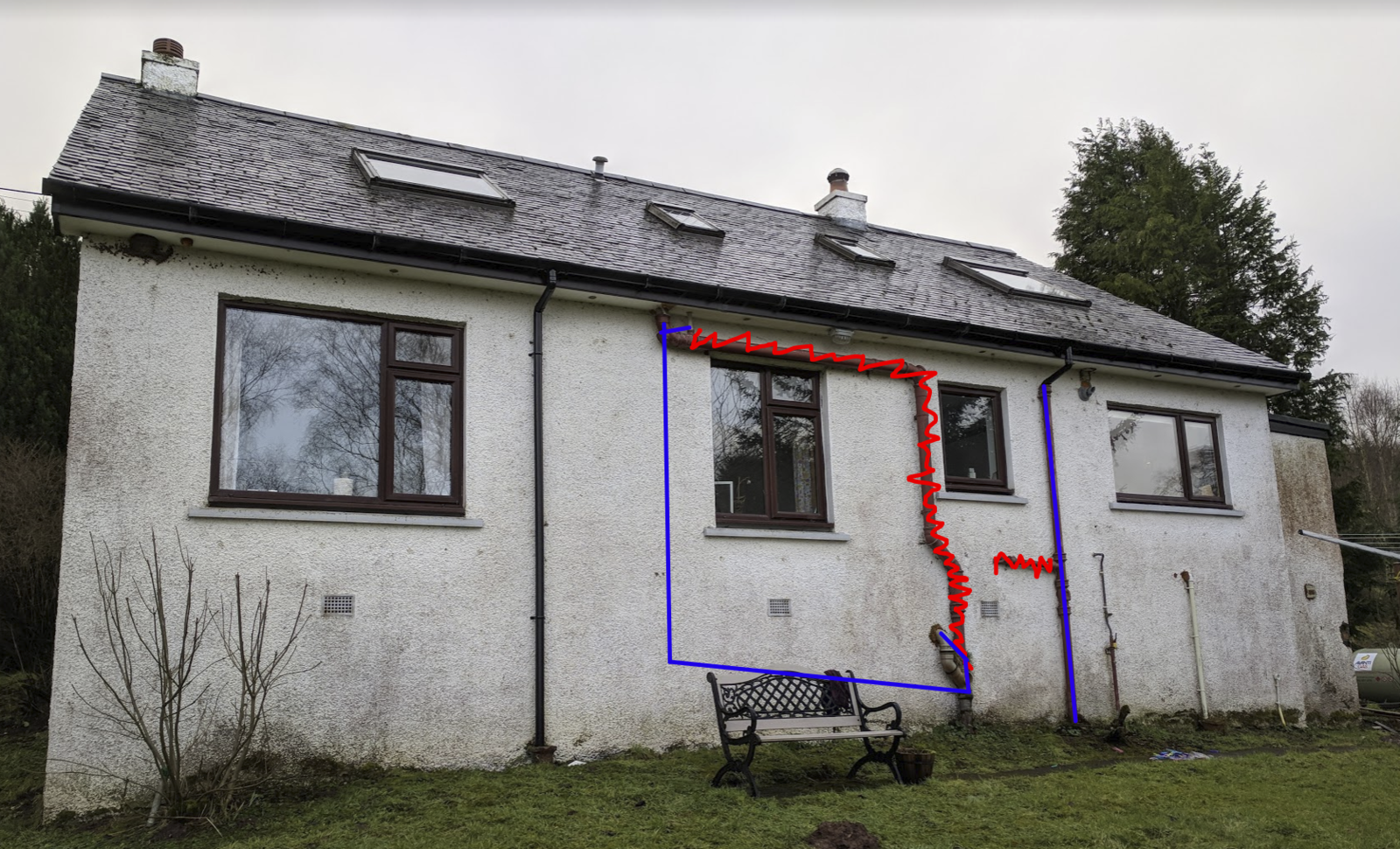

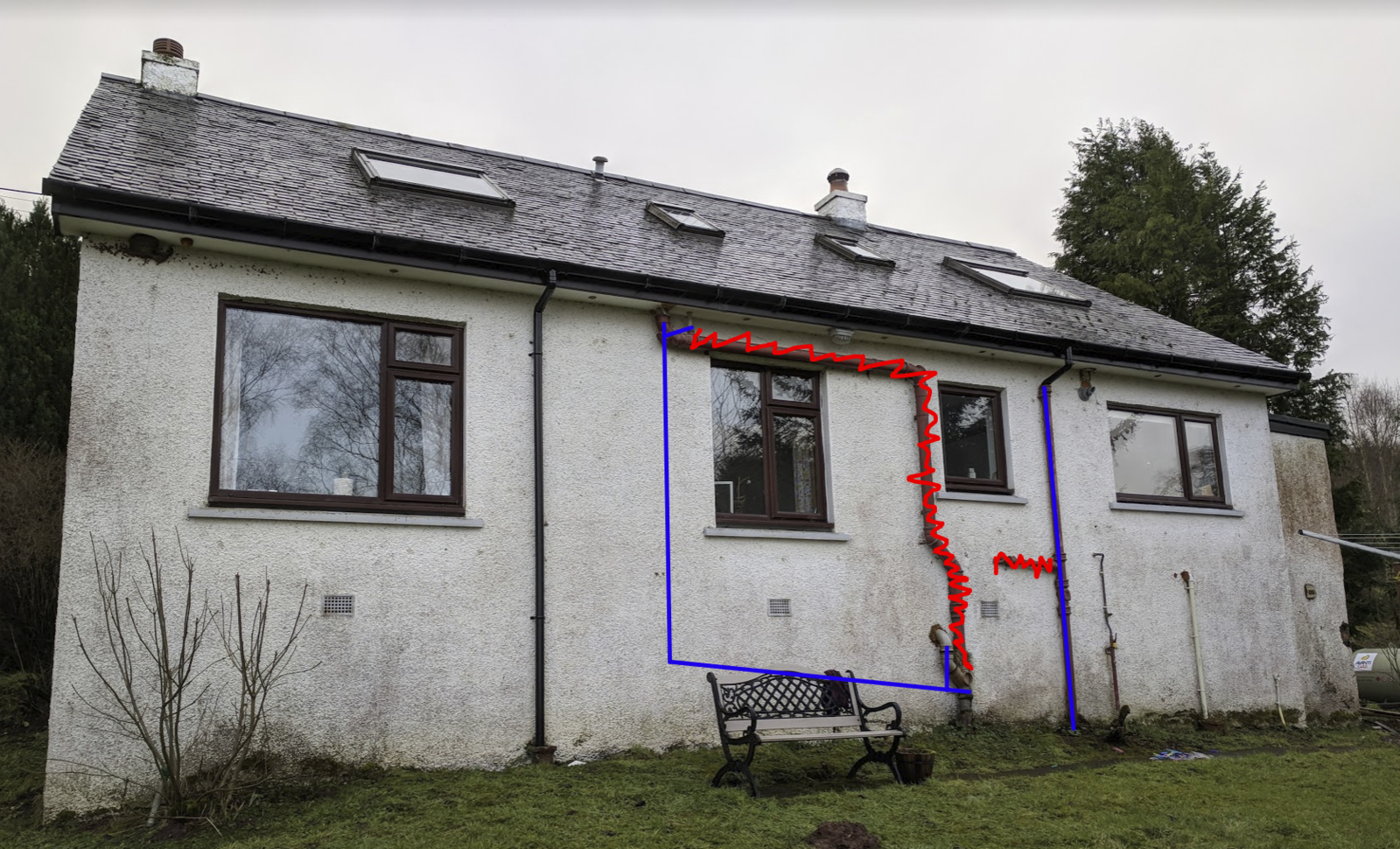

There are some sections of old cast pipe which go through the wall (at 3 points highlighted in image below) where the bathroom is but they are all now defunct. At some point, someone has put the soil into PVC and brought it through the wall in a new place, offset from the old cast soil pipe then connected to the old cast soil pipe in a rather dodgy looking manner. All the other waste pipes from the bathroom run into this under the floor so no cast pipe is actually doing anything.

There is also a soil pipe from the loft conversion bathroom which runs in a rather unsightly route that we want to re-route and renew. It doesn't seem to incorporate a soil vent (unless there is an air admittance valve in the eaves that I didn't notice).

My ideal solution is remove all cast pipework and replace both it and the existing pvc with new black PVC soil pipes with a tidier route. Also want to cut the cast soil pipe closer to the ground so only the black PVC can be seen before it ties into the cast bit.

I think the renderer is happy to do the section of gutter downpipe but I think I need to sort the soil pipe.

The main queries I have are as follows and I would be very grateful for your opinions/advice:

Any tips in general for dismantling cast pipe joints?

What should I do to remove the old cast pipe that goes through the wall? Just smash away anything that's left with a lump hammer and fill with brick offcuts & cement?

Whats my best option for layout of the junction of the downstairs soil pipe and upstairs soil pipe above where they will have to join into the cast soil pipe? (I have added a few pics of options and notes below. Please suggest any better ideas or suggest which you think makes most sense.)

Best method of cutting cast pipe (I have a 4" and a 6" angle grinder, any particular discs?)

What is the best way to connect the 110mm PVC to the to the cast soil pipe at the ground without restricting flow?

In this option, the downstairs soil pipe would tee straight into the side of the upstairs soil pipe as it comes out of the wall through a swept tee, instead of coming out through an elbow and going down. I am not sure whether the tee joint would be a problem in terms of flow where the two pipes meet but it seems the tidiest option?

In this option the downstairs soil would come out of the wall and go diagonally down to the line of the existing soil pipe, a vertical section would go down to the cast pipe with the upstairs soil teeing in before the cast/PVC joint.

in this option, the downstairs soil pipe continues directly down to tee into the top of the horizontal run of the upstairs soil pipe then there is an elbow above the joint between PVC and cast pipes.

There are some sections of old cast pipe which go through the wall (at 3 points highlighted in image below) where the bathroom is but they are all now defunct. At some point, someone has put the soil into PVC and brought it through the wall in a new place, offset from the old cast soil pipe then connected to the old cast soil pipe in a rather dodgy looking manner. All the other waste pipes from the bathroom run into this under the floor so no cast pipe is actually doing anything.

There is also a soil pipe from the loft conversion bathroom which runs in a rather unsightly route that we want to re-route and renew. It doesn't seem to incorporate a soil vent (unless there is an air admittance valve in the eaves that I didn't notice).

My ideal solution is remove all cast pipework and replace both it and the existing pvc with new black PVC soil pipes with a tidier route. Also want to cut the cast soil pipe closer to the ground so only the black PVC can be seen before it ties into the cast bit.

I think the renderer is happy to do the section of gutter downpipe but I think I need to sort the soil pipe.

The main queries I have are as follows and I would be very grateful for your opinions/advice:

Any tips in general for dismantling cast pipe joints?

What should I do to remove the old cast pipe that goes through the wall? Just smash away anything that's left with a lump hammer and fill with brick offcuts & cement?

Whats my best option for layout of the junction of the downstairs soil pipe and upstairs soil pipe above where they will have to join into the cast soil pipe? (I have added a few pics of options and notes below. Please suggest any better ideas or suggest which you think makes most sense.)

Best method of cutting cast pipe (I have a 4" and a 6" angle grinder, any particular discs?)

What is the best way to connect the 110mm PVC to the to the cast soil pipe at the ground without restricting flow?

In this option, the downstairs soil pipe would tee straight into the side of the upstairs soil pipe as it comes out of the wall through a swept tee, instead of coming out through an elbow and going down. I am not sure whether the tee joint would be a problem in terms of flow where the two pipes meet but it seems the tidiest option?

In this option the downstairs soil would come out of the wall and go diagonally down to the line of the existing soil pipe, a vertical section would go down to the cast pipe with the upstairs soil teeing in before the cast/PVC joint.

in this option, the downstairs soil pipe continues directly down to tee into the top of the horizontal run of the upstairs soil pipe then there is an elbow above the joint between PVC and cast pipes.