I have a Makita 18v LXT li-ion cordless drill which has suddenly stopped working.

The battery is fully charged but there does not appear to be power getting to the brushes.

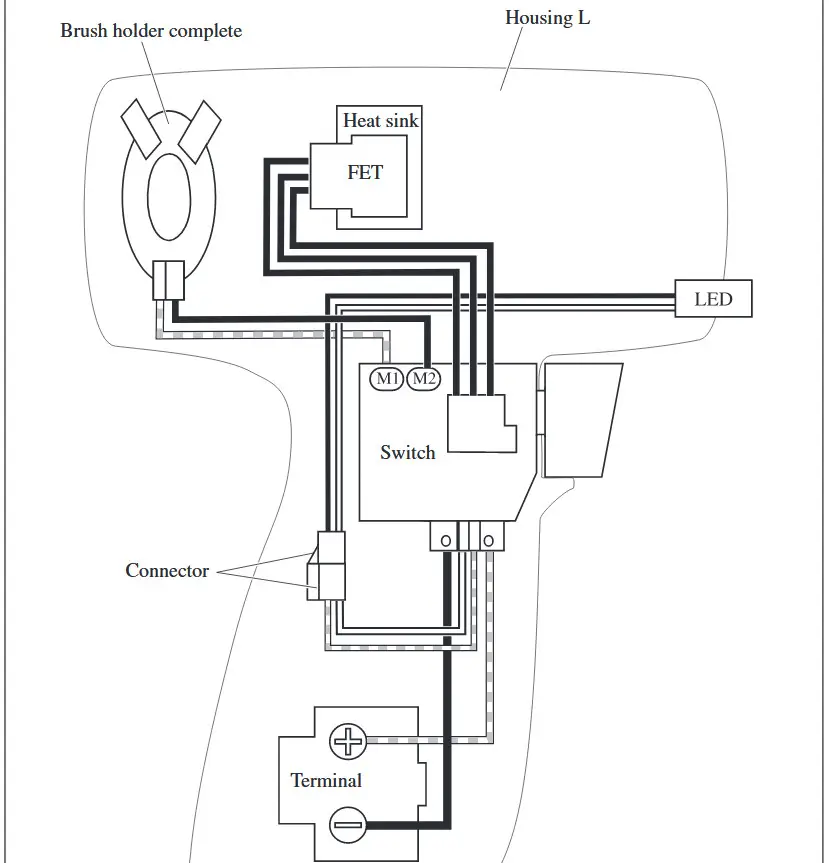

I am wondering if it could be something to do with the sensor (labelled FET in the attached schematic) which is attached to the heatsink and wired to the trigger - but I'm not sure how this works so don't know how to test it.

Anyone any thoughts?

The battery is fully charged but there does not appear to be power getting to the brushes.

I am wondering if it could be something to do with the sensor (labelled FET in the attached schematic) which is attached to the heatsink and wired to the trigger - but I'm not sure how this works so don't know how to test it.

Anyone any thoughts?