- Joined

- 17 May 2025

- Messages

- 21

- Reaction score

- 1

- Country

Hi

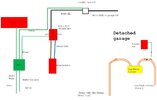

I have 10mm main bonding to the water main from the MET in the house, and to the gas pipe at the boiler , the gas meter is in a detached garage next to the house, the garage electrics are fed to the garage from a Volex shower unit fed from 16mm tails via 4mm swa cable.

Plus there is a 10mm earth cable going to the 4mm swa junction box in the loft ( swa is also earthed each end !

Now the question has I have bonding to the gas pipe in the house, do I still need main bonding to the gas meter in the detached garage, the gas meter has suplimentary bonding to it from the garage cu !.

Has per drawing.

I have 10mm main bonding to the water main from the MET in the house, and to the gas pipe at the boiler , the gas meter is in a detached garage next to the house, the garage electrics are fed to the garage from a Volex shower unit fed from 16mm tails via 4mm swa cable.

Plus there is a 10mm earth cable going to the 4mm swa junction box in the loft ( swa is also earthed each end !

Now the question has I have bonding to the gas pipe in the house, do I still need main bonding to the gas meter in the detached garage, the gas meter has suplimentary bonding to it from the garage cu !.

Has per drawing.

Attachments

Last edited: