Someone recently (I think it was RF Lighting) posted a picture of a very neatly done CU where the cables clearly exited the CU at the rear, behind the breakers.

And I can see how that makes it easier to do a neat job - sheath stripped back to out of sight, phase conductors looped up and back down into the MCBs etc.

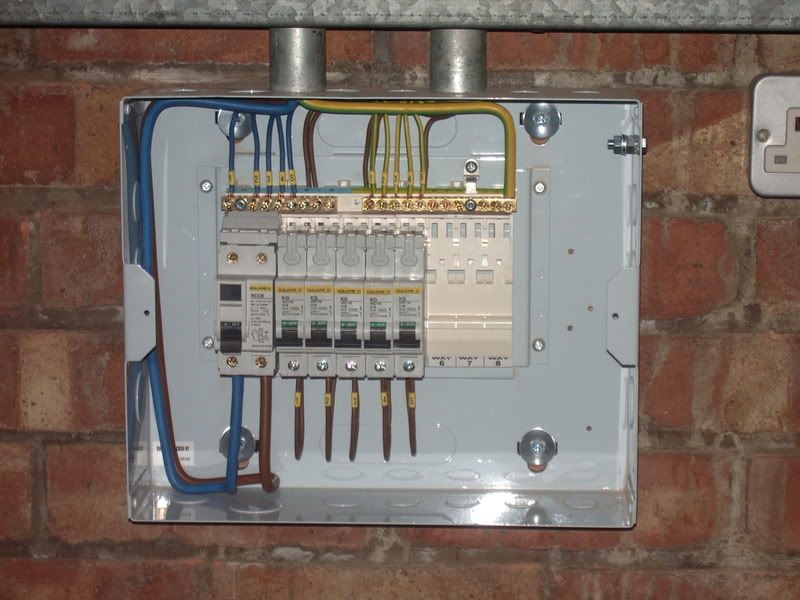

Any suggestions on how to keep things neat and tidy when the cables have to exit through the top of the enclosure? There are two rows of breakers BTW, and it's over 300mm from the top of the lower row to the top of the enclosure, and somewhere they'll have to negotiate earth and neutral bars - although I've not decided where I'm going to put those yet...

. Did think of putting them at the very bottom, as then I wouldn't have to route conductors over/past them, but then I would have to deal with N & E cores 500mm long....

. Did think of putting them at the very bottom, as then I wouldn't have to route conductors over/past them, but then I would have to deal with N & E cores 500mm long....

And I can see how that makes it easier to do a neat job - sheath stripped back to out of sight, phase conductors looped up and back down into the MCBs etc.

Any suggestions on how to keep things neat and tidy when the cables have to exit through the top of the enclosure? There are two rows of breakers BTW, and it's over 300mm from the top of the lower row to the top of the enclosure, and somewhere they'll have to negotiate earth and neutral bars - although I've not decided where I'm going to put those yet...