bought a Securit fire door closer (class 3 )

Instructions are dreadful and maybe it's C...p.

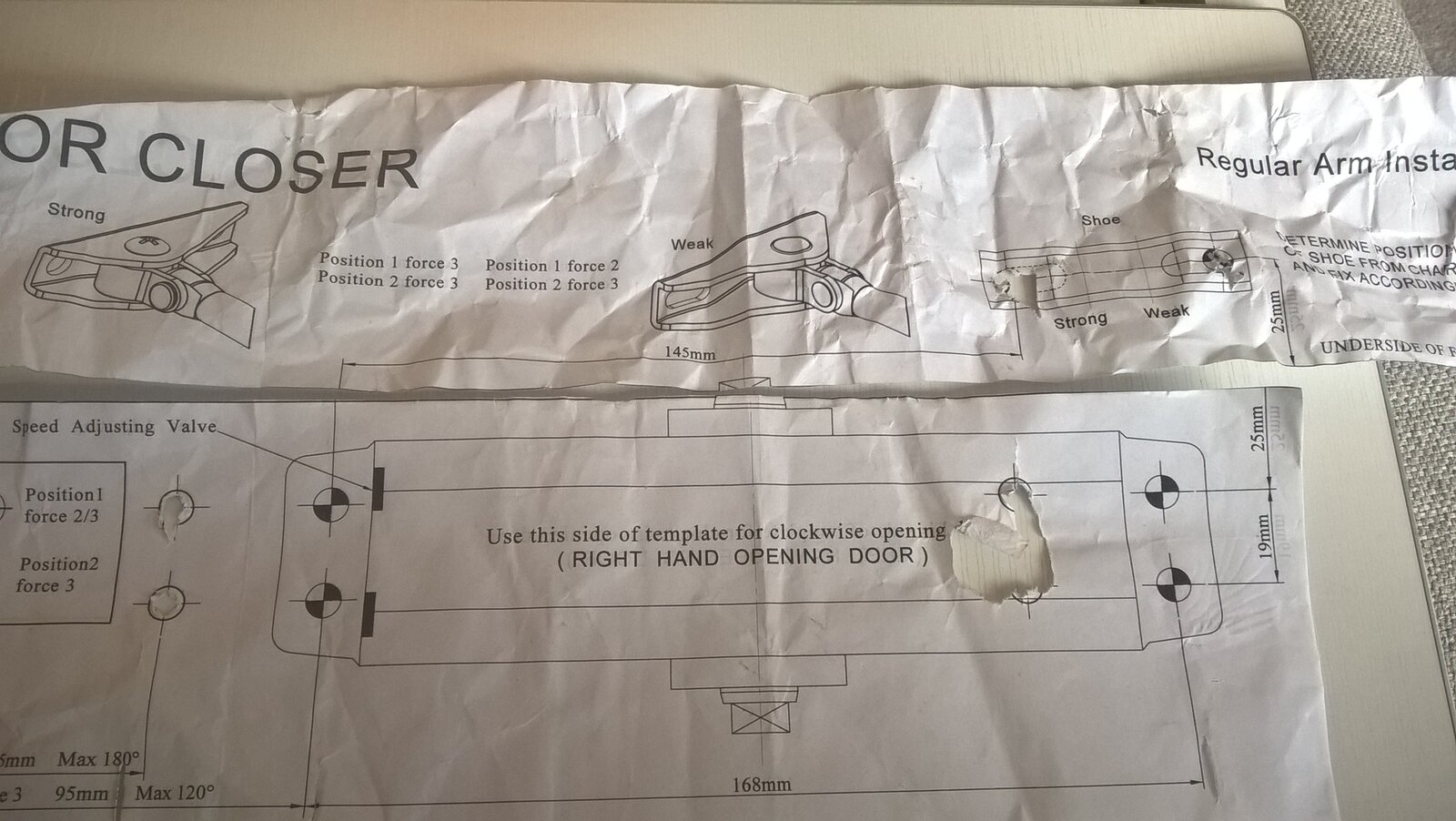

We went for (position 1) force 2/3 because we wanted it to open more than 120 deg.

The template gives the location of the screws for fixing the body, ie LH screws 65mm in from the hinge edge of the door-all good

Now for the positioning of the foot for the adjustable arm fixing, it gives a measurement of 145mm from the LH screw IF YOU USE POSITION 2 and only shows a slight difference in scre position for strong or weak

question 1- we used position 1, so should the shoe have been fixed 145mm from LH screw on the body, or should we just follow the template?(which is what we did)

the spindle for the main arm is square, but the hole in the main arm is hex shaped and doesn't seem to go onto the spindle easily

question 2- is there a particular way to get it on and should it go right down over the spindle ?

the instructions don't specifically mention the words "pre loading"(they do on the instructions for parallel fixing), but seem to suggest to separate the 2 arms, place the main arm onto the spindle so it's at 90 deg to the door and put the nut on to tighten it

Then fix the adjustable arm to the shoe and , keeping it at 90 deg to the door, pull the main arm around to meet the adjustable arm.

question 3 Would this pre-load the opener?

the opener isn't closing the door right up .Appreciate it might be the hinges or another problem, but regarding the closer, we're adjusting the 1 and 2 (closing speed and latching speed) adjustments, but it doesn't seem to making much difference.The door closes fine without the closer and locks and latchs fine.

It doesn't have a power adjustment.

question 4- would we have been better to use Position 2 ie max opening 120 deg'?

Instructions are dreadful and maybe it's C...p.

We went for (position 1) force 2/3 because we wanted it to open more than 120 deg.

The template gives the location of the screws for fixing the body, ie LH screws 65mm in from the hinge edge of the door-all good

Now for the positioning of the foot for the adjustable arm fixing, it gives a measurement of 145mm from the LH screw IF YOU USE POSITION 2 and only shows a slight difference in scre position for strong or weak

question 1- we used position 1, so should the shoe have been fixed 145mm from LH screw on the body, or should we just follow the template?(which is what we did)

the spindle for the main arm is square, but the hole in the main arm is hex shaped and doesn't seem to go onto the spindle easily

question 2- is there a particular way to get it on and should it go right down over the spindle ?

the instructions don't specifically mention the words "pre loading"(they do on the instructions for parallel fixing), but seem to suggest to separate the 2 arms, place the main arm onto the spindle so it's at 90 deg to the door and put the nut on to tighten it

Then fix the adjustable arm to the shoe and , keeping it at 90 deg to the door, pull the main arm around to meet the adjustable arm.

question 3 Would this pre-load the opener?

the opener isn't closing the door right up .Appreciate it might be the hinges or another problem, but regarding the closer, we're adjusting the 1 and 2 (closing speed and latching speed) adjustments, but it doesn't seem to making much difference.The door closes fine without the closer and locks and latchs fine.

It doesn't have a power adjustment.

question 4- would we have been better to use Position 2 ie max opening 120 deg'?