You just need to connect the sonoff to home assistant and it will do the rest. Pretty sure there is an integration for sonoff or flash it to tasmota to keep it local.This is sadly very interesting. How do you do this from a Sonoff TH10?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Adding extra temperature sensor to hot water tank

- Thread starter Sammy21

- Start date

- Joined

- 2 Mar 2020

- Messages

- 82

- Reaction score

- 11

- Country

Slightly off topic but I thought some may be interested in the destratification pump. In short it doesn't circulate. I thought at first that either the double check valve was sticking or the pump was faulty. Alas no. After several emails and phone calls to the pump manufacturer and reading of the pump curves, I contacted the cylinder manufacturer. This took several attempts as the people on the helpline in India were clueless about this discontinued product. Today I managed to speak to a gentleman with a Brummie accent who knows his stuff and he told me that the cylinder has too high a resistance to fit a pump. He said several people tried over the years to do what I have done and none have been successful. I don't know if that's good to know or what but what a waste of time and expense. At least I didn't pay full price for the pump as it was off ebay, unboxed but unused. In retrospect I should have done this first but I've never heard of this problem before, as I've had destrat pumps fitted to loads of cylinders and calorifiers at work in the past.Just an update Harry. I installed the pump a couple of days ago. The pump is installed between the outlet and cold water inlet. I installed a double check valve prior to the pump and one on the cold water feed prior to where the pump tees into the cold water feed if you get my drift [If not I will try to explain better]. The pipe immediately after the the pump gets mad hot when the pump is activated but cools off after a foot. The system pressure is about 3.5bar and I'm not sure as to the "actual" flowrate of the destratification pump under these conditions. I expected a more rapid flow of water but it does work when I check the boiler readout where the sensor is at a similar level to the cold water inlet and the outlet Sonoff sensor. What I have noticed is that the 1 hour I have set the DHW to heat up the 300L cylinder is not enough to heat it up to anywhere near 60C from a 40C baseline. I will make adjustments as required as I do not want legionella in the system.

- Joined

- 19 Nov 2020

- Messages

- 74

- Reaction score

- 9

- Country

@Pete the Feet Not sure what resistance they’re talking about. Seems you’re just putting in a secondary recirculating system with a very short run.

- Joined

- 2 Mar 2020

- Messages

- 82

- Reaction score

- 11

- Country

That's what I thought, but he was straight out with it and was obviously very aware of the situation. When the cylinder was initially installed I think it may have been the same chap I spoke to when I contacted them about the water hammer when an outside tap was opened. He knew the solution straight off, so I do respect his knowledge. Also the cylinder is discontinued now.@Pete the Feet Not sure what resistance they’re talking about. Seems you’re just putting in a secondary recirculating system with a very short run.

- Joined

- 2 Mar 2020

- Messages

- 82

- Reaction score

- 11

- Country

@Pete the Feet Not sure what resistance they’re talking about. Seems you’re just putting in a secondary recirculating system with a very short run.

Just what I thought on both counts. Draining down is a right pita, but I'll give it a go. I was going to try it without the check valve, then isolate as a test but the draining down is a rainy or snowy day job.A double spring check valve installed on the pump suction possibly the problem, probably ok if installed to the pump discharge, or install a swing check valve.

I must add that I ran the outlet side of the pump into the cold water feed as the return connection is more than half way up the cylinder and I didn't think it would be very effective there. Its the bottom of the cylinder that is extremely cold due to the make up. The last resort will be using the designated return connection. However by the sounds of the man from Ariston, that wouldn't work either. I did however try to get it circulating by isolating the mains water and even letting it depressurise but it still wouldn't circulate.

Last edited:

- Joined

- 2 Mar 2020

- Messages

- 82

- Reaction score

- 11

- Country

A Wilo SB30, bronze.

- Joined

- 2 Mar 2020

- Messages

- 82

- Reaction score

- 11

- Country

I finally got around to draining the system and fitting an additional isolation valve in order to experiment with and without check valves. Last week I removed the double check valve from the suction side of the pump and lo and behold it worked. However the downside of this is it won't work if you draw water off as it short circuits the cylinder. Today I fitted the double check valve in the the pump delivery and it didn't work; no surprises there. Now I don't know whether to try and easily available single check or search out a swing check, bearing in mind that it will be installed in a vertical pipe with the flow heading downwards to the base of the cylinder. No doubt a swing check won't be available in 22mm compression.A double spring check valve installed on the pump suction possibly the problem, probably ok if installed to the pump discharge, or install a swing check valve.

The swing check wont work in a vertical pipe pumping downwards as it will just hang down.

A normal single check valve has a cracking (opening) pressure of ~ 0.5bar (5M), I have measured one opening at a 3M head, you may be able to get a Low Pressure Check valve that you can install on the pump discharge but it will have to have a cracking pressure of 0.25M or less if the

Wilo SB30 has a max dead head of 3M.

A normal single check valve has a cracking (opening) pressure of ~ 0.5bar (5M), I have measured one opening at a 3M head, you may be able to get a Low Pressure Check valve that you can install on the pump discharge but it will have to have a cracking pressure of 0.25M or less if the

Wilo SB30 has a max dead head of 3M.

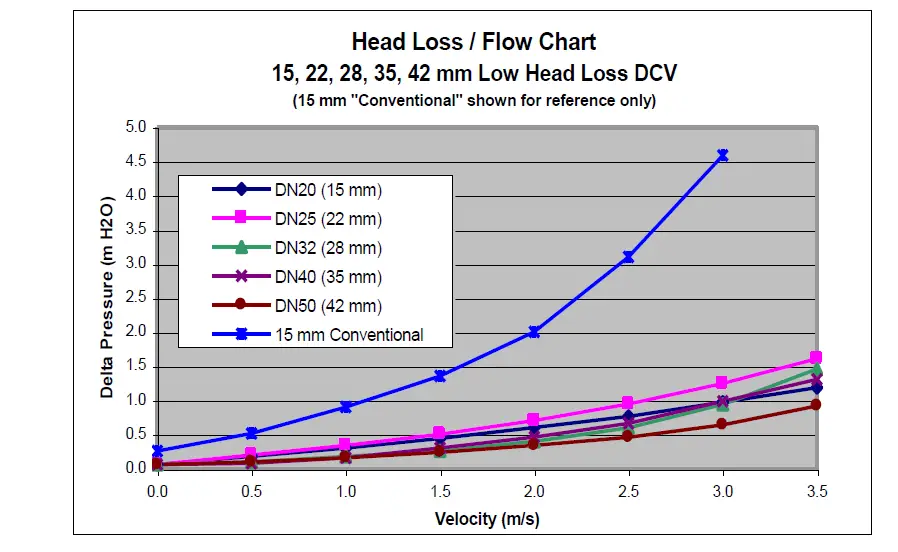

Here is a 22mm double check valve that should do the job, it will give well less than 0.5M head loss at 1m/s which is, by my calcs, 23LPM. (Arrow Valves). They show a 15mm conventional valve as having ~ 2m loss at 2m/s to give the the same flowrate of 23LPM so surprising that your pump wasn't able to circulate at least 10LPM (1 m/s) at a head loss of less than 1M?. Can you post the pump curves.

Attachments

Last edited:

- Joined

- 2 Mar 2020

- Messages

- 82

- Reaction score

- 11

- Country

Hi John, here is the link to the website with the pump curves:

I will source one of these valves as it will make for a better job than having to dog leg the pipe for a BP valve. The trouble when you just buy a check valve or fitting from a local supplier or Screwfix, they probably don't have that sort of data available regarding flow rate.

I bought the pump with very little thought to this problem, seeing as it was only intended to pump around the cylinder, which it does without a check valve. How it would fare as a secondary pump around the system wouldn't look too promising.

Many thanks for your help by the way, I really do appreciate it.

I will source one of these valves as it will make for a better job than having to dog leg the pipe for a BP valve. The trouble when you just buy a check valve or fitting from a local supplier or Screwfix, they probably don't have that sort of data available regarding flow rate.

I bought the pump with very little thought to this problem, seeing as it was only intended to pump around the cylinder, which it does without a check valve. How it would fare as a secondary pump around the system wouldn't look too promising.

Many thanks for your help by the way, I really do appreciate it.

- Joined

- 2 Mar 2020

- Messages

- 82

- Reaction score

- 11

- Country

Hi John

Its the Ariston Primo ITI 300L indirect. I have branched off the flow within a few inches of the cylinder and fed into the cold water makeup rather than the secondary return connection, which is higher up the cylinder.

I've had a look at the Arrow check valve and they are expensive. An alternative may be the Reliance single check from Toolstation.

Its the Ariston Primo ITI 300L indirect. I have branched off the flow within a few inches of the cylinder and fed into the cold water makeup rather than the secondary return connection, which is higher up the cylinder.

I've had a look at the Arrow check valve and they are expensive. An alternative may be the Reliance single check from Toolstation.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 8

- Views

- 9K

A

- Replies

- 0

- Views

- 1K

- Replies

- 3

- Views

- 1K

- Replies

- 7

- Views

- 2K

- Replies

- 2

- Views

- 1K