- Joined

- 18 Sep 2019

- Messages

- 20

- Reaction score

- 0

- Country

Hi all,

After years of hanging around this site, I finally have a big enough project of my own to share. I am building a garden room (yes... it's another garden room post) with a view to discovering if I can learn enough skills to eventually build my own timber frame house extension (which I think is the more exciting bit).

I'll need a little help along the way and am happy to hear ideas, criticism, or even the occasional "You aren't mad for trying" comment.

I have a few questions that I couldn't find the answers to in other threads, but I'll outline the details here first.

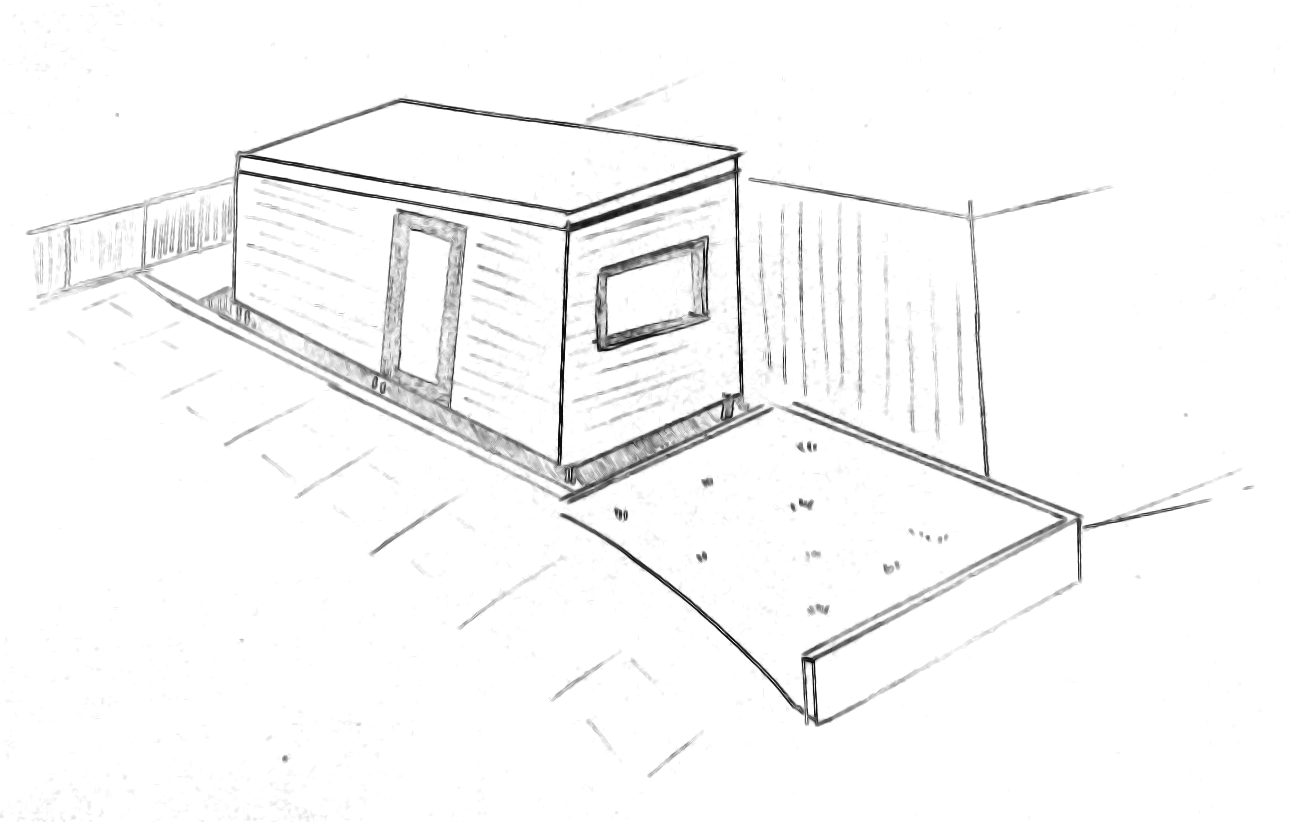

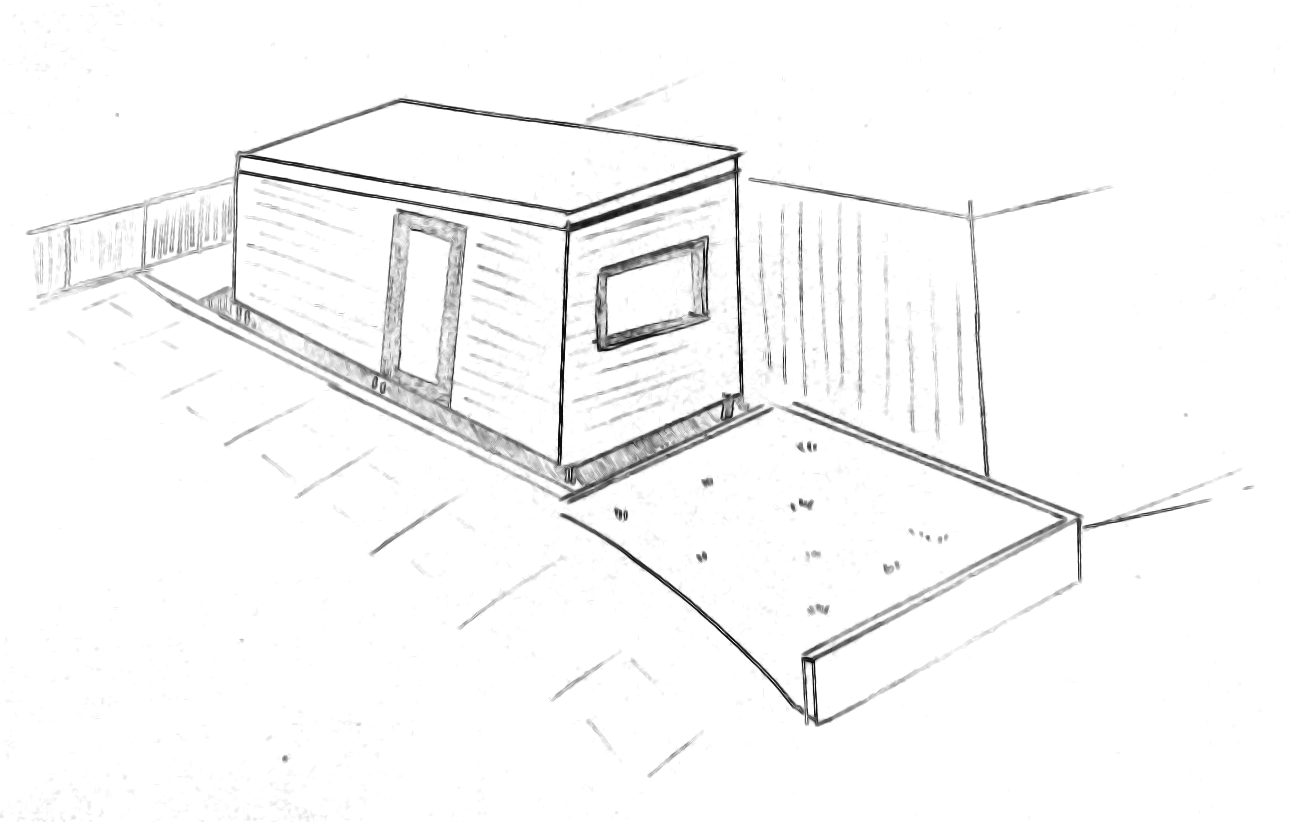

Foot print and design

The room will be a modest 2.2m by 3m, and with a low height of 2.5m from the original ground. It'll be used primarily as a place to sit with a laptop and work, so I have somewhere to go that isn't my kitchen table. This is incidental use to the house so won't require planning permission, and the footprint means I won't require building control sign off either. Result.

It will be up against a boundary facing a road and I want it to be as unobtrusive for the neighbours as possible, so I'll have the roof sloping down towards the road so the neighbours see the shortest side. This also means the highest point is at the end I will sit, by the window checking that kids aren't misbehaving in the garden, which is important because we don't have kids.

Foundations

I've opted for ground screws. The floor is heavy clay and I am looking at using 750mm ground screws. I'll dig down 200mm in the current position, and build a retaining wall around the perimeter of the room. This gives me a bit more space to play with to keep under the 2.5m height restriction as that is measured from the original ground level immediately adjacent to the building. I'll have to make sure there is good drainage otherwise the building being on ground-screw stilts and the collected water within the retaining walls will make it into a 'Little Venice' in my own garden.

Window and door

My partner and I had an argument about this - I wanted to use a second hand door and window I had found on ebay at a great price to save money. My other half wanted to get brand new ones custom made to exactly match our initial thoughts on sizes. ... Long story short, we will be going for brand new ones.

Structure

It'll be a stick build timber frame, the current plan being stud walls from 47x100mm C24 timbers, sheathed in 11m OSB3, with 80mm of PIR insualtion and plasterboard on the inside. With a breather membrane. Of course.

Floor will also be 47 by 100mm joists (which meets the requirements of the span tables as there will be ground screw supports in the middle of the structure as well), with 80mm PIR and an 18mm OSB3 deck. I'll throw in a vapour barrier for good measure - no expense spared.

Roof

I'm looking for a warm roof (accepted wisdom seems to be that they are the way to go, and it makes sense to practice this seeing as I might need this skill for the house extension roof later).

Plans here are a little more hazy.

Joists: The e-book I bought on garden rooms suggested a 100x47mm joist with noggins, but the span tables say I need a 120x47mm C24 joist for the shortest distance in this roof design.

This will be topped with an OSB3 18mm deck, 80mm PIR insulation, 11mm OSB3 and then finally an EPDM membrane.

This gives a roof thickness of 251mm, which cuts into the 2.5m allowance quite a lot and a low ceiling like that risks scraping off what's left of my hair.

Cladding

This changes each time I see something new and exciting, but the current plan is Fibre cement tiles. Lighter and cheaper than slate but a similar feel. In reality, there is a strong chance that my ADHD tendencies will kick in and I'll end up with a different type of cladding on every wall, making it look like something from Playschool. Please keep me on track if you see me wavering here in future posts.

I'll take photos and keep people updated with the build in case you want to learn from or laugh at my journey.

QUESTIONS

If any of the (brighter than me) people on this forum could help me out on a few points before I start digging that would be great.. really amazing.

Question 1 - floor

With me digging down to lower the floor level, is there anything I have missed here that means I need to do extra things to protect the building?

I will leave 100mm from the weed membrane to the base of the timber floor to allow for airflow, and then the first 100mm of the floor deck will be adjacent to the retaining wall, below original ground level. Is there anything extra I need to do here to prevent problems with damp?

Question 2 - ROOF JOIST THICKNESS

Forgive the elemental question, but can I get away with 47x100 C24 joists on a garden building at 400mm levels to save me an extra 20mm of head height? The span table for building control suggests I should be looking at 120mm joists for a span of 2.2m.

A linked question, is would regular noggins help in providing strength to the roof structure, allowing me to get away with the slightly thinner joists?

Question 3 - ROOF JOIST DIRECTION

For reasons stated above, we want the slope of the roof to be along the longest length of the building (the 3m side) which I am told is a little unusual. In my plan, I currently have the joists going across the shortest width (2.2m). Does it matter that the 6 degree slope of the roof is at right angles to the direction of the joists?

Thanks so much for any light people can shed on the above. I'm looking forward to sharing photo updates with you all.

Best,

Jack.

P.S. Picture attached. I am no artist. To the left of the garden room you see a drive way that slopes down, in front of the garden room is a little bit of grass. To the right of the garden room is a shed from the mid 90s. I got too depressed drawing it so that bit of the drawing is unfinished.

After years of hanging around this site, I finally have a big enough project of my own to share. I am building a garden room (yes... it's another garden room post) with a view to discovering if I can learn enough skills to eventually build my own timber frame house extension (which I think is the more exciting bit).

I'll need a little help along the way and am happy to hear ideas, criticism, or even the occasional "You aren't mad for trying" comment.

I have a few questions that I couldn't find the answers to in other threads, but I'll outline the details here first.

Foot print and design

The room will be a modest 2.2m by 3m, and with a low height of 2.5m from the original ground. It'll be used primarily as a place to sit with a laptop and work, so I have somewhere to go that isn't my kitchen table. This is incidental use to the house so won't require planning permission, and the footprint means I won't require building control sign off either. Result.

It will be up against a boundary facing a road and I want it to be as unobtrusive for the neighbours as possible, so I'll have the roof sloping down towards the road so the neighbours see the shortest side. This also means the highest point is at the end I will sit, by the window checking that kids aren't misbehaving in the garden, which is important because we don't have kids.

Foundations

I've opted for ground screws. The floor is heavy clay and I am looking at using 750mm ground screws. I'll dig down 200mm in the current position, and build a retaining wall around the perimeter of the room. This gives me a bit more space to play with to keep under the 2.5m height restriction as that is measured from the original ground level immediately adjacent to the building. I'll have to make sure there is good drainage otherwise the building being on ground-screw stilts and the collected water within the retaining walls will make it into a 'Little Venice' in my own garden.

Window and door

My partner and I had an argument about this - I wanted to use a second hand door and window I had found on ebay at a great price to save money. My other half wanted to get brand new ones custom made to exactly match our initial thoughts on sizes. ... Long story short, we will be going for brand new ones.

Structure

It'll be a stick build timber frame, the current plan being stud walls from 47x100mm C24 timbers, sheathed in 11m OSB3, with 80mm of PIR insualtion and plasterboard on the inside. With a breather membrane. Of course.

Floor will also be 47 by 100mm joists (which meets the requirements of the span tables as there will be ground screw supports in the middle of the structure as well), with 80mm PIR and an 18mm OSB3 deck. I'll throw in a vapour barrier for good measure - no expense spared.

Roof

I'm looking for a warm roof (accepted wisdom seems to be that they are the way to go, and it makes sense to practice this seeing as I might need this skill for the house extension roof later).

Plans here are a little more hazy.

Joists: The e-book I bought on garden rooms suggested a 100x47mm joist with noggins, but the span tables say I need a 120x47mm C24 joist for the shortest distance in this roof design.

This will be topped with an OSB3 18mm deck, 80mm PIR insulation, 11mm OSB3 and then finally an EPDM membrane.

This gives a roof thickness of 251mm, which cuts into the 2.5m allowance quite a lot and a low ceiling like that risks scraping off what's left of my hair.

Cladding

This changes each time I see something new and exciting, but the current plan is Fibre cement tiles. Lighter and cheaper than slate but a similar feel. In reality, there is a strong chance that my ADHD tendencies will kick in and I'll end up with a different type of cladding on every wall, making it look like something from Playschool. Please keep me on track if you see me wavering here in future posts.

I'll take photos and keep people updated with the build in case you want to learn from or laugh at my journey.

QUESTIONS

If any of the (brighter than me) people on this forum could help me out on a few points before I start digging that would be great.. really amazing.

Question 1 - floor

With me digging down to lower the floor level, is there anything I have missed here that means I need to do extra things to protect the building?

I will leave 100mm from the weed membrane to the base of the timber floor to allow for airflow, and then the first 100mm of the floor deck will be adjacent to the retaining wall, below original ground level. Is there anything extra I need to do here to prevent problems with damp?

Question 2 - ROOF JOIST THICKNESS

Forgive the elemental question, but can I get away with 47x100 C24 joists on a garden building at 400mm levels to save me an extra 20mm of head height? The span table for building control suggests I should be looking at 120mm joists for a span of 2.2m.

A linked question, is would regular noggins help in providing strength to the roof structure, allowing me to get away with the slightly thinner joists?

Question 3 - ROOF JOIST DIRECTION

For reasons stated above, we want the slope of the roof to be along the longest length of the building (the 3m side) which I am told is a little unusual. In my plan, I currently have the joists going across the shortest width (2.2m). Does it matter that the 6 degree slope of the roof is at right angles to the direction of the joists?

Thanks so much for any light people can shed on the above. I'm looking forward to sharing photo updates with you all.

Best,

Jack.

P.S. Picture attached. I am no artist. To the left of the garden room you see a drive way that slopes down, in front of the garden room is a little bit of grass. To the right of the garden room is a shed from the mid 90s. I got too depressed drawing it so that bit of the drawing is unfinished.