You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bosch Condenser Dryer "Clean Container" (secret flap door)

- Thread starter klaani

- Start date

- Joined

- 18 Apr 2017

- Messages

- 2

- Reaction score

- 0

- Country

I had the same problem. My 1 year old Bosch Maxx 7 sensitive condenser dryer would stop after a minute or so and would indicate a full tank of water. Filter was clean, water tank empty, cooler filter think from the front bottom left of dryer was clean, made me crazy!

Found this great post, took apart my dryer, hoses clean, no problem... Then I found a "secret door" flap, whatever, located in the bottom panel in the slot where the large cooler/filter thing goes. It is in the way back on the bottom. Lies flat has two hinges that you pull in with your fingernails towards you. Lift the flap up and you have a small holding area that gets full of gelatinized sludge! Pulled out about a cup full of lint filled slime gel, dried everything, put cover back on, viola! Works like new.

You don't even have to take the dryer apart if you can find the secret flap! Oh well, at least I know how to take it apart if I ever get bored. Thanks a million for the posts you great, helpful people!

- Joined

- 18 Apr 2017

- Messages

- 2

- Reaction score

- 0

- Country

Me too - with a bit of a kink

I moved house and adapted the classixx 7 sensitive drier to draininto the w/m drain outlet, then I stacked it on top of W/M in a narrow cupboard. Thanks to Matt the builder!

(The "adapting" involved taking the top off and prying a space open through the slotted grill on the back - bye bye warranty)

1st point - I did not spot the soft black rubber hose at the bottom of the rear of the machine when I did this -

If I had I would not have found this great post and all the even more grateful readers

So I got the container full light after one successful load.

I read the post - did not see the 2 slots on the floor of the condenser channel the first time

(- really difficult - use a torch )

Began to fret I had invalidated the warranty by altering the back grill to get the drain hose out

(which I discovered today I had not needed to do)

Felt brave today so had another go and read the post really carefully, used a torch, found the slots, had to use to paint stripping shave hooks to pull and lift the flap.

The sump under the flap was pooled with water but no gunge.

Cleaned and dried it and ran the drier for 20 minutes but the warning light came on again

Used a cloth again to dry the sump - no warning light for 15 minutes.

Point 2. The warning light comes on when sump is full for whatever reason, otherwise it will overflow onto the floor - I tested this by pouring excess water into the sump.

Now I took the side panel off (left as you look at from the front) - you have to take the electric control and switches panel off to do this - SWITCH OFF THE ELECTRICITY FIRST

Then I saw how I had kinked the previously mentioned SOFT BLACK RUBBER TUBE,

So I reconnected the SBRT inside the machine at the top to the container filler

And disconnected it outside the machine at the bottom

(and pushed it onto the little grey solid plastic spigot put right beside the drain spigot especially for the purpose)

I then connected some slightly stiffer transparent plastic tubing to the drain spigot

- which is what I should have done in the first place !

- I have switched one of the internal pipe clips on the outside to support this pipe so it does not kink

Machine running now but I shall leave it on the hall floor draining into a plastic bin for a few loads until I am happy it is clear, or until Matt the builder comes back.

I really enjoyed this thread - never seen so many grateful readers - and not a single mention of Hitler or any other fascist (obviously until now )

I moved house and adapted the classixx 7 sensitive drier to draininto the w/m drain outlet, then I stacked it on top of W/M in a narrow cupboard. Thanks to Matt the builder!

(The "adapting" involved taking the top off and prying a space open through the slotted grill on the back - bye bye warranty)

1st point - I did not spot the soft black rubber hose at the bottom of the rear of the machine when I did this -

If I had I would not have found this great post and all the even more grateful readers

So I got the container full light after one successful load.

I read the post - did not see the 2 slots on the floor of the condenser channel the first time

(- really difficult - use a torch )

Began to fret I had invalidated the warranty by altering the back grill to get the drain hose out

(which I discovered today I had not needed to do)

Felt brave today so had another go and read the post really carefully, used a torch, found the slots, had to use to paint stripping shave hooks to pull and lift the flap.

The sump under the flap was pooled with water but no gunge.

Cleaned and dried it and ran the drier for 20 minutes but the warning light came on again

Used a cloth again to dry the sump - no warning light for 15 minutes.

Point 2. The warning light comes on when sump is full for whatever reason, otherwise it will overflow onto the floor - I tested this by pouring excess water into the sump.

Now I took the side panel off (left as you look at from the front) - you have to take the electric control and switches panel off to do this - SWITCH OFF THE ELECTRICITY FIRST

Then I saw how I had kinked the previously mentioned SOFT BLACK RUBBER TUBE,

So I reconnected the SBRT inside the machine at the top to the container filler

And disconnected it outside the machine at the bottom

(and pushed it onto the little grey solid plastic spigot put right beside the drain spigot especially for the purpose)

I then connected some slightly stiffer transparent plastic tubing to the drain spigot

- which is what I should have done in the first place !

- I have switched one of the internal pipe clips on the outside to support this pipe so it does not kink

Machine running now but I shall leave it on the hall floor draining into a plastic bin for a few loads until I am happy it is clear, or until Matt the builder comes back.

I really enjoyed this thread - never seen so many grateful readers - and not a single mention of Hitler or any other fascist (obviously until now )

Many thanks Bnaji, I have just cleaned the 'secret' area and all is well. I did it with a wet sucking vacuum (as I had the fridge freezer go - so luckily was in process of defrosting) if only you had a pound for all us grateful Bosch Drier users!!!!

A couple of comments:

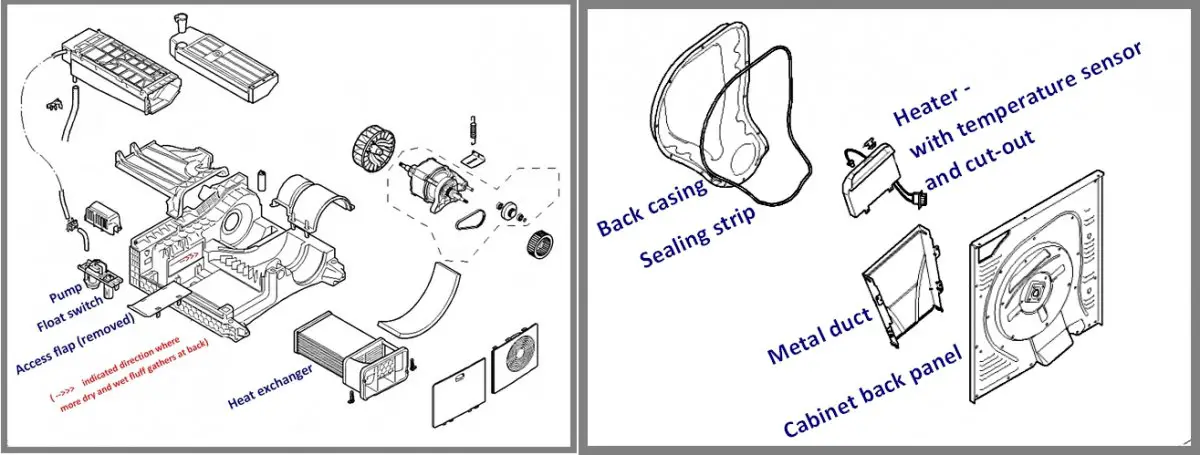

The way I lift the access flap in the plastic floor under the (removed) heat-exchanger is to use a very short screwdriver to push one of the clips forward and lever up that side of the flap. I have a long, thin screwdriver ready to push under that end of the flap. I then use the short screwdriver to push the other clip forward, and the flap pops up. The diagram shows the layout.

I recommend exploring the far reaches of the air passage at the back and to the right (shown by red arrows in the diagram). I have found dry fluff accumulated in the air channels at the very back. I also used a long 'test-tube' brush and found soggy compacted fluff lower down. There seems to be a water collecting sump back there (it is practically at the back right-hand corner of the machine between the motor and the back panel). I sucked more soggy fluff out using a long plastic tube connected to a wet/dry vacuum cleaner. So it looks as though the sump under the access flap beneath the heat exchanger is not the only collecting space for the condensed water.

With the right-hand side panel partially removed, I could not see any obvious way to open up the plastic parts to gain access. Bosch/Siemens parts diagram does not indicate that the back right parts open up. Bosch/Siemens seem to assume you'll just throw the fluffed-up machine away after six or seven years!

It is straight-forward, and worthwhile, to remove the rear casing and the metal duct; and clean them. Once unscrewed, the heater will be captive on its wires but can be moved about enough to clean it out. Compressed air would be ideal for blowing the heater elements clear of fluff. I found the temperature sensor was wrapped in a blanket of tight fluff. The safety cut-out has a red button - check it is pressed in before fixing the back casing in place. I had bought a replacement seal, but did not need it. Beware the screws: coarse threads go into plastic; fine threads go into metal.

The way I lift the access flap in the plastic floor under the (removed) heat-exchanger is to use a very short screwdriver to push one of the clips forward and lever up that side of the flap. I have a long, thin screwdriver ready to push under that end of the flap. I then use the short screwdriver to push the other clip forward, and the flap pops up. The diagram shows the layout.

I recommend exploring the far reaches of the air passage at the back and to the right (shown by red arrows in the diagram). I have found dry fluff accumulated in the air channels at the very back. I also used a long 'test-tube' brush and found soggy compacted fluff lower down. There seems to be a water collecting sump back there (it is practically at the back right-hand corner of the machine between the motor and the back panel). I sucked more soggy fluff out using a long plastic tube connected to a wet/dry vacuum cleaner. So it looks as though the sump under the access flap beneath the heat exchanger is not the only collecting space for the condensed water.

With the right-hand side panel partially removed, I could not see any obvious way to open up the plastic parts to gain access. Bosch/Siemens parts diagram does not indicate that the back right parts open up. Bosch/Siemens seem to assume you'll just throw the fluffed-up machine away after six or seven years!

It is straight-forward, and worthwhile, to remove the rear casing and the metal duct; and clean them. Once unscrewed, the heater will be captive on its wires but can be moved about enough to clean it out. Compressed air would be ideal for blowing the heater elements clear of fluff. I found the temperature sensor was wrapped in a blanket of tight fluff. The safety cut-out has a red button - check it is pressed in before fixing the back casing in place. I had bought a replacement seal, but did not need it. Beware the screws: coarse threads go into plastic; fine threads go into metal.

Last edited:

- Joined

- 15 Sep 2017

- Messages

- 1

- Reaction score

- 0

- Country

I want to thank everyone that has suggested and discover the secret door,I have traveled many lands and fought many wars to be conquered by the secret door, only to find another warrior here in this matrix call the internet and found the way to the secret door, I thank you my fellow warrior may you all discover the way to happy drying machines oh yeah and happy wife, Thank you from Germany!

Last edited by a moderator:

My wife found this thread and would line to thank bnaji and everyone else who posted about the secret panel and other helpful tips! Sludge removed from secret compartment didn't solve the issue until she also pulled out large wedge of dry fluff from back of tunnel! Now working great again... must be getting on for 10 years old! What did we do before the internet!

must be getting on for 10 years old! What did we do before the internet!

The clothes were all put on line....... the washing line

MHI PLEASE CAN SOME ONE HELP ME!! I've read every single thread but still unsure where to locate this secret flap. Ny machine looks like this, its the self cleaning maax 7. It's only just over a year old and suddenly its not drying clothes and some times the cycle finishes when its not dry and it's not collecting water ... where is the water going?? We've cleaned the filters, scrubbed the sensor for limescale and i dont know what to do but its stressing me out. this 'secret' flap you refer to.. is it on the front under the door or do we need to unscrew the back? Please am desperate! thanks!

Attachments

MHI PLEASE CAN SOME ONE HELP ME!! I've read every single thread but still unsure where to locate this secret flap. Ny machine looks like this, its the self cleaning maax 7. It's only just over a year old and suddenly its not drying clothes and some times the cycle finishes when its not dry and it's not collecting water ... where is the water going?? We've cleaned the filters, scrubbed the sensor for limescale and i dont know what to do but its stressing me out. this 'secret' flap you refer to.. is it on the front under the door or do we need to unscrew the back? Please am desperate! thanks!

Read more: https://www.diynot.com/diy/threads/...-container-issues.248668/page-6#ixzz53LYhIk2D

Read more: https://www.diynot.com/diy/threads/...-container-issues.248668/page-6#ixzz53LYhIk2D

Attachments

- Joined

- 30 Mar 2018

- Messages

- 2

- Reaction score

- 0

- Country

MHI PLEASE CAN SOME ONE HELP ME!! I've read every single thread but still unsure where to locate this secret flap. Ny machine looks like this, its the self cleaning maax 7. It's only just over a year old and suddenly its not drying clothes and some times the cycle finishes when its not dry and it's not collecting water ... where is the water going?? We've cleaned the filters, scrubbed the sensor for limescale and i dont know what to do but its stressing me out. this 'secret' flap you refer to.. is it on the front under the door or do we need to unscrew the back? Please am desperate! thanks!

Read more: https://www.diynot.com/diy/threads/...-container-issues.248668/page-6#ixzz53LYhIk2D

On our machine - there's door on the bottom left that you have to open. Looks like you don't have that. Take the water reservoir at the top completely out and look inside with a torch and you will probably see the secret flap. Good luck.

MHI PLEASE CAN SOME ONE HELP ME!! I've read every single thread but still unsure where to locate this secret flap. Ny machine looks like this, its the self cleaning maax 7. It's only just over a year old and suddenly its not drying clothes and some times the cycle finishes when its not dry and it's not collecting water ... where is the water going?? We've cleaned the filters, scrubbed the sensor for limescale and i dont know what to do but its stressing me out. this 'secret' flap you refer to.. is it on the front under the door or do we need to unscrew the back? Please am desperate! thanks!

Read more: https://www.diynot.com/diy/threads/...-container-issues.248668/page-6#ixzz53LYhIk2D

Sorry - managed to post that before answering!!!

If the machine is only a year old it should still be covered by the guarantee....I would go down that route first. If you start poking around with screwdrivers etc they might use that as excuse to void the guarantee.

If they won't cover it I would then start looking at how to remove the side panels and back etc, maybe look at their spare parts diagrams on the Bosch Website to try and work out where the water is going - I imagine it works like the one this thread is about.

The water collects in the bottom (under the secret flap) and it is pumped up a pipe to the collection tank all on the LHS of the machine. You might be able to see the pipe at the back - some of these machines allow you to feed the water collection into a drain so you don't need to empty the tank - you can see a small section of the pipe at the bottom of the machine...

Once you can locate the pump you need to check the area around the pump and that the pipe isn't blocked (or kinked)...

Also have you read your instruction manual? That might have a troubleshooting guide etc which could help ...(although the secret flap isn't mentioned in the instruction manuals for the non-self cleaning machines....)

If the machine is only a year old it should still be covered by the guarantee....I would go down that route first. If you start poking around with screwdrivers etc they might use that as excuse to void the guarantee.

If they won't cover it I would then start looking at how to remove the side panels and back etc, maybe look at their spare parts diagrams on the Bosch Website to try and work out where the water is going - I imagine it works like the one this thread is about.

The water collects in the bottom (under the secret flap) and it is pumped up a pipe to the collection tank all on the LHS of the machine. You might be able to see the pipe at the back - some of these machines allow you to feed the water collection into a drain so you don't need to empty the tank - you can see a small section of the pipe at the bottom of the machine...

Once you can locate the pump you need to check the area around the pump and that the pipe isn't blocked (or kinked)...

Also have you read your instruction manual? That might have a troubleshooting guide etc which could help ...(although the secret flap isn't mentioned in the instruction manuals for the non-self cleaning machines....)

Just found this flap in my Clasixx 7. Pulled one of the retaining tabs back towards me and at the same time inserted a thin bit of metal, bit like a nail file, under the flap which was enough to raise one side. I left the metal under the flap to ti keep it raised and then pulled the other retaining tab back towards me and the flap popped up.

Put my hand inside a sock and grabbed all the grunge out. So far the machine is working fine without the collection light coming on and the machine stopping.

Heres a youtube video that I have since found that explains how to access the flap..

Put my hand inside a sock and grabbed all the grunge out. So far the machine is working fine without the collection light coming on and the machine stopping.

Heres a youtube video that I have since found that explains how to access the flap..

Last edited:

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 1

- Views

- 8K

- Replies

- 4

- Views

- 9K