Hello,

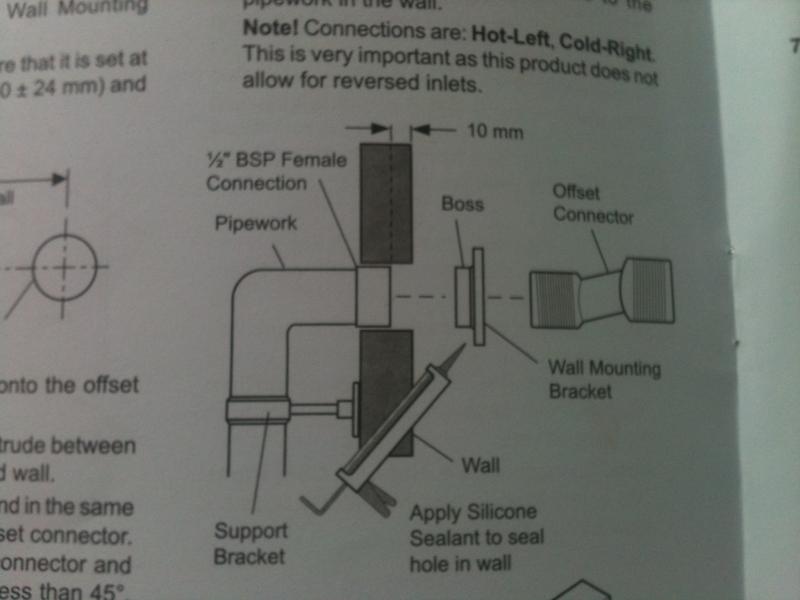

I'm about to bury some plumbing behind some tiles so I'd really like to get it right. I bought a Mira shower and you are supposed to fit it to a partition like this:

I have bought these from Wall Plate Elbows Toolstation to get me from Polyplumb 15mm too the shower fixing of a 1/2" BSP:

http://www.toolstation.com/shop/p85095

Here is an end-on view of the toolstation elbow (right) and the shower fitting (left):

The plan is just to screw the thread together with loads of PTFE tape in there to form a permanent watertight seal. Here is a picture of it dry fitted:

Is this what you would do? Or do I need a tap connector like for an appliance with a rubber bit in the end? I'm pretty sure PTFE and these fittings will work but once they're buried I'm in a real mess if they leak!

I'd be really grateful for any advice from someone who knows what they're doing!

Thanks.

I'm about to bury some plumbing behind some tiles so I'd really like to get it right. I bought a Mira shower and you are supposed to fit it to a partition like this:

I have bought these from Wall Plate Elbows Toolstation to get me from Polyplumb 15mm too the shower fixing of a 1/2" BSP:

http://www.toolstation.com/shop/p85095

Here is an end-on view of the toolstation elbow (right) and the shower fitting (left):

The plan is just to screw the thread together with loads of PTFE tape in there to form a permanent watertight seal. Here is a picture of it dry fitted:

Is this what you would do? Or do I need a tap connector like for an appliance with a rubber bit in the end? I'm pretty sure PTFE and these fittings will work but once they're buried I'm in a real mess if they leak!

I'd be really grateful for any advice from someone who knows what they're doing!

Thanks.