Hi There

I have had ongoing issues with my central heating since moving in 18 months ago.

The main issue was the ground floor rads being luke warm at best - particularly when the HW was on. Balancing didn't really help much!

Since Christmas we have been having boiler lock out issues that are 'ignition faults' and so with the numerous engineers that have tried to help and provide us with quotes - we keep getting different answers and suggestions to our problems. We are now not knowing what to do, other than try to understand out system and understand it for ourselves.

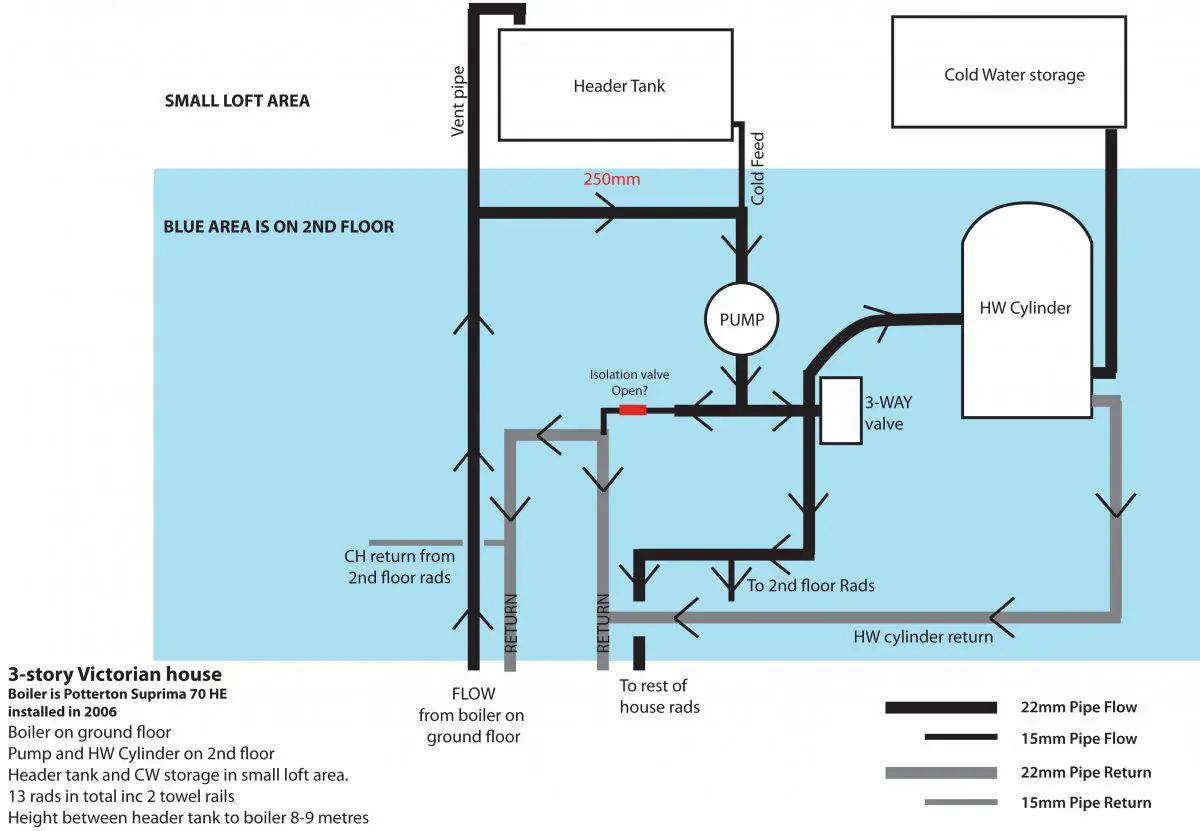

I want to get to the route of the cause and not just fix the symptoms - I think with some research I have done (and an engineer who is willing to try and help us through this), that it may come down to the pipework design up in our airing cupboard.

My notes below give a brief description of symptoms and what has been suggested by engineers and how to fix it.

We believe our system is fairly old and has lots of isolation valve scattered around so we are a bit nervous about doing anything too harsh to it.

Symptoms

A. Boiler is sporadically/regularly locking out

B. When pump turns on - vent sucks in air

C. When pump turns off vent spits small amount of water

D. When CH or HW on the cold feed gets very hot and

header tank water turns warm

E. 2 Rads on ground floor never get as hot as others

Obvious Issues

1. Vent and Cold feed too far apart

2. Vent pipe not 450mm above water line

3. Poor pipework design after pump.

4. No Balancing valve on HW tank

Other possible issues

1. Sludge in system - (Thermal image

suggests otherwise) Have tried Fernox F5

2. Cold Feed Tee blocked

3. Pump not large enough

4. Unbalanced system - have tried this

previous to Fernox F5 without much success.

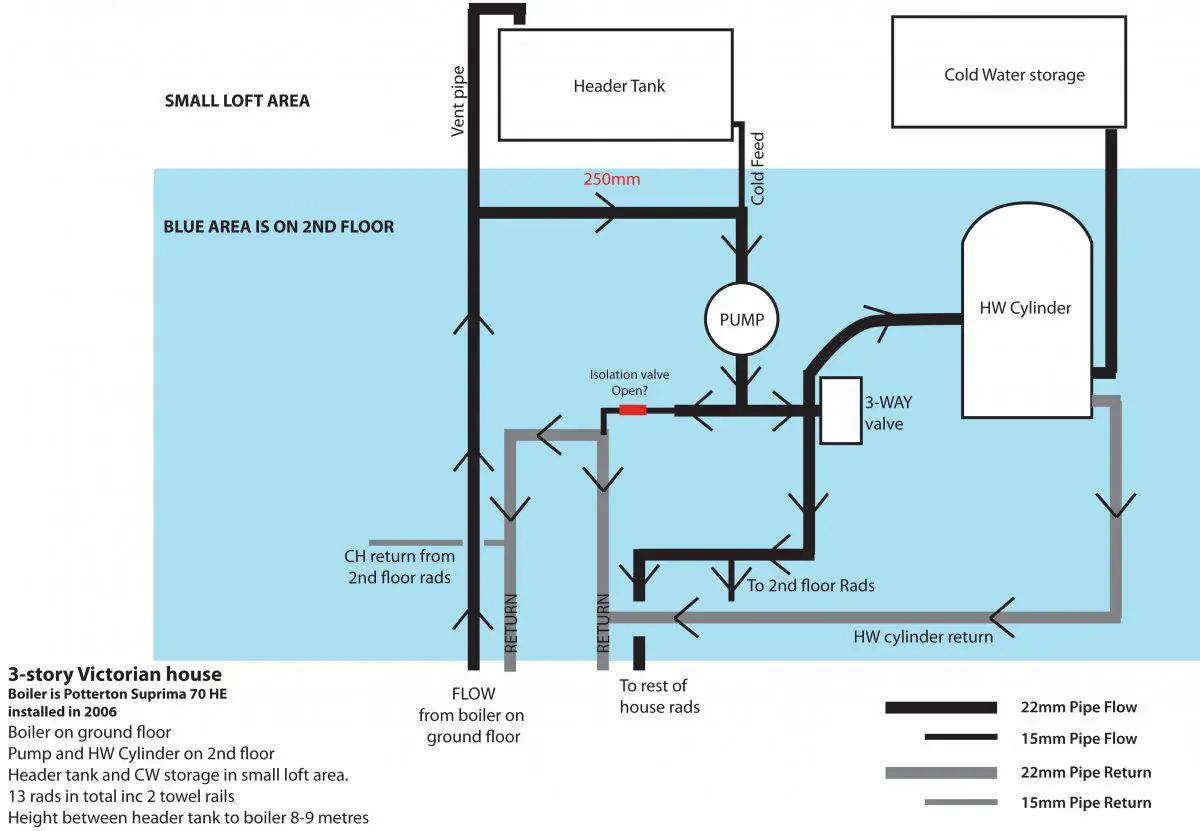

I have drawn a diagram of the pipework - can anyone see anything glaringly obvious which could be causing lock outs with the boiler or flow issues to the ground floor?

Any help would be greatfully received.

Marrianne

I have had ongoing issues with my central heating since moving in 18 months ago.

The main issue was the ground floor rads being luke warm at best - particularly when the HW was on. Balancing didn't really help much!

Since Christmas we have been having boiler lock out issues that are 'ignition faults' and so with the numerous engineers that have tried to help and provide us with quotes - we keep getting different answers and suggestions to our problems. We are now not knowing what to do, other than try to understand out system and understand it for ourselves.

I want to get to the route of the cause and not just fix the symptoms - I think with some research I have done (and an engineer who is willing to try and help us through this), that it may come down to the pipework design up in our airing cupboard.

My notes below give a brief description of symptoms and what has been suggested by engineers and how to fix it.

We believe our system is fairly old and has lots of isolation valve scattered around so we are a bit nervous about doing anything too harsh to it.

Symptoms

A. Boiler is sporadically/regularly locking out

B. When pump turns on - vent sucks in air

C. When pump turns off vent spits small amount of water

D. When CH or HW on the cold feed gets very hot and

header tank water turns warm

E. 2 Rads on ground floor never get as hot as others

Obvious Issues

1. Vent and Cold feed too far apart

2. Vent pipe not 450mm above water line

3. Poor pipework design after pump.

4. No Balancing valve on HW tank

Other possible issues

1. Sludge in system - (Thermal image

suggests otherwise) Have tried Fernox F5

2. Cold Feed Tee blocked

3. Pump not large enough

4. Unbalanced system - have tried this

previous to Fernox F5 without much success.

I have drawn a diagram of the pipework - can anyone see anything glaringly obvious which could be causing lock outs with the boiler or flow issues to the ground floor?

Any help would be greatfully received.

Marrianne