- Joined

- 27 Jan 2008

- Messages

- 23,670

- Reaction score

- 2,668

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

Been considering brewing lager and for this to work temperature is important. It would seem most people use a stc-1000 thermostat designed really to keep fish at right temperature it seems this has two relays one for heat and one for cooling and most use an old fridge but for this to work it needs to be where it is always too hot.

So my idea was a use a cool box unit which will both heat and cool. This needs 12VDC but the power supplies for LED lights are quite cheap. So should be three states cool, do nothing or heat.

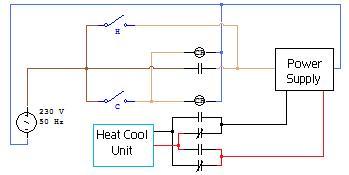

I think it needs two relays one to reverse the DC side and one to allow power to power supply when either heat or cool required. So quick idea of circuit required below.

I have a number of thoughts as to what problems I may have from 12v rather then 13.8v to cool box unit to fans wearing out in cool box unit plus got to make a cool box big enough to take fermentor.

I am also uncertain if really worth the effort to make Lager or if to just drink the simulated stuff with standard yeast. However would like to see comments before going too far both here for electric side and brew forum for brewing side.

What I can't understand is why this is not a standard method is seems to fit the bill so why is it not already the standard method?

So my idea was a use a cool box unit which will both heat and cool. This needs 12VDC but the power supplies for LED lights are quite cheap. So should be three states cool, do nothing or heat.

I think it needs two relays one to reverse the DC side and one to allow power to power supply when either heat or cool required. So quick idea of circuit required below.

I have a number of thoughts as to what problems I may have from 12v rather then 13.8v to cool box unit to fans wearing out in cool box unit plus got to make a cool box big enough to take fermentor.

I am also uncertain if really worth the effort to make Lager or if to just drink the simulated stuff with standard yeast. However would like to see comments before going too far both here for electric side and brew forum for brewing side.

What I can't understand is why this is not a standard method is seems to fit the bill so why is it not already the standard method?