- Joined

- 27 Jan 2008

- Messages

- 23,679

- Reaction score

- 2,668

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

I worked mainly commercial and in most distribution boards I have worked on the release tag for the MCB is under the output terminal so to swap a MCB was a simple operation you switched off removed cable slacked off terminal to bus bar released tag and lifted clear very simple.

However I came to swap one for my daughter she had this BG 10-Way High Integrity Populated Insulated Consumer Unit Dual 63A RCD fitted and the release tags were under the bus bars so to remove one MCB the whole bus bar needed to be removed.

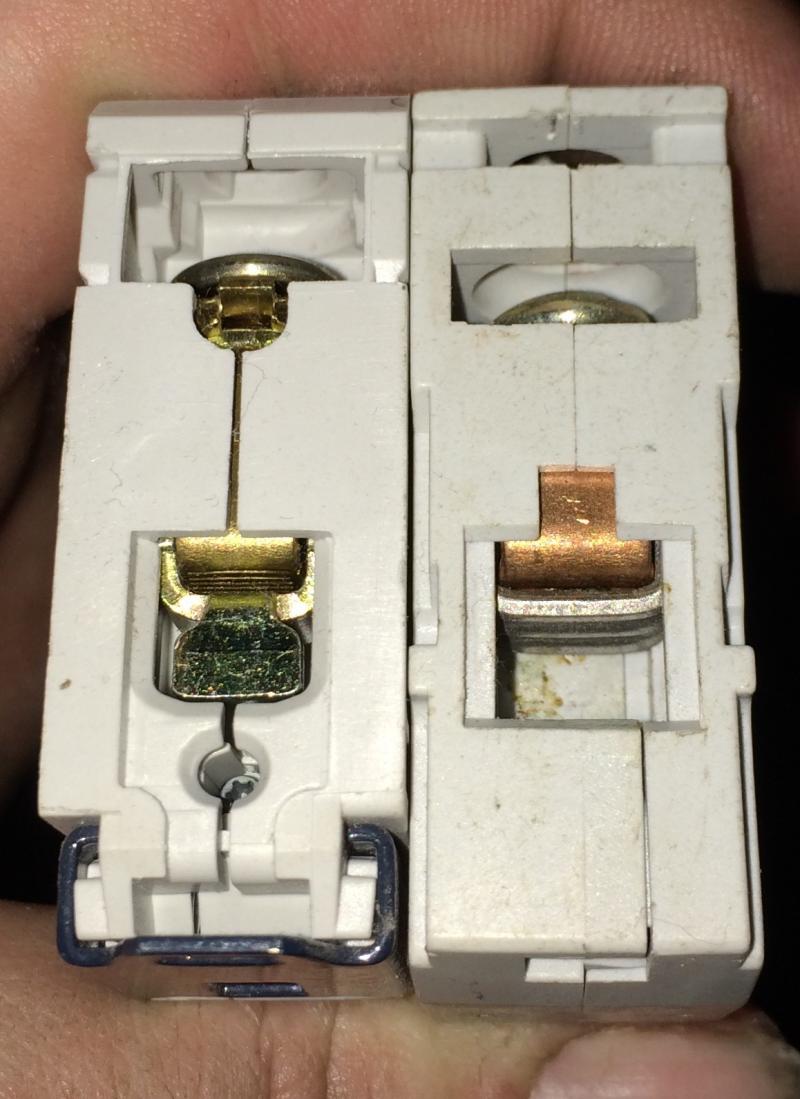

On refitting the bus bar one had to be very careful to ensure the terminals were open it was very easy to get the bus bar below the clamp rather than in the clamp. Laid on it back with original fitting not a problem but once fitted it really needed a special tool to press on all 6 terminal screws to ensure the clamps were open I had to really struggle with a mirror to ensure the bus bar was inserted correctly.

I am now not surprised there are consumer unit fires it would be so easy for an MCB to be only touching the bus bar rather than clamping onto it and clearly any torque screwdriver would do nothing to redress this problem.

I am sure other consumer units I have used the bus bars were fixed and the MCB was actually clamped in not by the din rail clip but by the bus bar and if you got terminal clamp wrong side of bus bar the MCB would be lose so easy to detect. Is this just a cheap and nasty consumer unit?

However I came to swap one for my daughter she had this BG 10-Way High Integrity Populated Insulated Consumer Unit Dual 63A RCD fitted and the release tags were under the bus bars so to remove one MCB the whole bus bar needed to be removed.

On refitting the bus bar one had to be very careful to ensure the terminals were open it was very easy to get the bus bar below the clamp rather than in the clamp. Laid on it back with original fitting not a problem but once fitted it really needed a special tool to press on all 6 terminal screws to ensure the clamps were open I had to really struggle with a mirror to ensure the bus bar was inserted correctly.

I am now not surprised there are consumer unit fires it would be so easy for an MCB to be only touching the bus bar rather than clamping onto it and clearly any torque screwdriver would do nothing to redress this problem.

I am sure other consumer units I have used the bus bars were fixed and the MCB was actually clamped in not by the din rail clip but by the bus bar and if you got terminal clamp wrong side of bus bar the MCB would be lose so easy to detect. Is this just a cheap and nasty consumer unit?