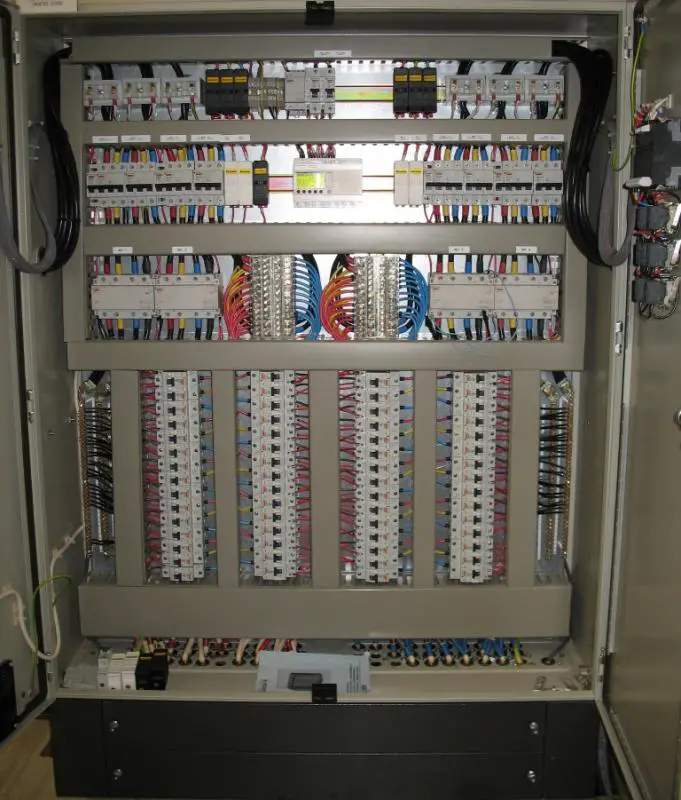

Loving that board, take a flat section of copper, drill holes willy-nilly and tap a shread into it. Sure you'd be able to get the proper amount of torque on that without the thread getting stripped?

No complliance to British Standards on the part of the manufacturer, thats trading standards issue.

Is the manufacturer a GSSE metalwork student with a big garage and a dad with a load of tools?

No complliance to British Standards on the part of the manufacturer, thats trading standards issue.

Is the manufacturer a GSSE metalwork student with a big garage and a dad with a load of tools?