- Joined

- 27 Jan 2018

- Messages

- 183

- Reaction score

- 23

- Country

Ecotec 418 open vented

S-Plan

2 Port HW & CH Valves

Standard HW/CH timer and roomsat/cylstat

Pump 15/50 - Speed 3

ABV installed (setting 2) between pump/valves and return back before the Magnaclean but its on a 15mm not 22mm pipe

10 Radiators (6xType10,2xType20,1xVertical double column, 1xType11

CH Temp 75c

Magnaclean Pro

Old 1910 house with solid walls, insulated loft to 250mm (not in kitchen extension)

Ive got an old thread which was related to this annoying boiler, issues come and go.

https://www.diynot.com/diy/threads/vaillant-418-s53-s7-after-new-radiator.496679/

In recent months as its got colder ive noticed system low firing on S53 especially when HW/CH is being demanded at the same time or when the system starts up from cold, as it gets hot it can go to S07 as the out water temp goes over set point but does not scale back quick enough.

The S07 has been a long standing issue as it can also happen on HW.

Ive scaled back D00 from 16 to 10 and S07 is not such a big problem any more until the whole system comes up to a flow diff temp of about 25c then its rising too much anyway.

Magnaclean has not been too dirty other than when initial powerclean was done back in 2017/18.

Its hard to get the house temp much over 19/20 and takes a long time to get there from cold which based on rad outputs seems to indicate its on the limit of output and will need some rads to be be sized up.

After reading lots of threads im considering the following.

1. The system needs a clean, MC3 etc for a few days, heat exchanger may be sludged then redose MC1

2. Install VR66 to give HW priority control for boiler firing

3. Replace a few of the Type10 radiators for Type 11/21/22 space dependent. They are over 25 years old (when I first moved in, not sure when prior owners had them installed but ile say add another 10 years on that, first powerflush removed tonnes of crud from them). Some places the size makes no sense, ie the hall is huge as it its length of the house and open right to the top but its got a really tiny radiator (7m long, 8m+ to top and 2m wide)

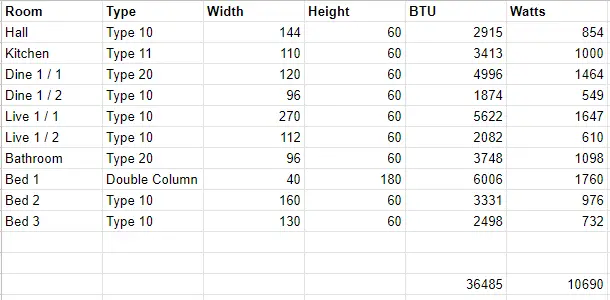

Below is my calculations based on Type10/P1 figures that stelrad show, does not account for age/corrosion/paint emissivity as prior owners have painted rads etc. Silly me its the first time ive actually done the calculation in all these years, I always suspected it was low due to age of house and nearly all type10. The upgrade of one radiator in 2018 actually pushed the BTU up for that room by 2k.

Anyway my real question was, is there any way the VR66 can be used with standard timers or would it need a VRT350/VRC700 to control it.

Its not well documented but if there is no eBUS timer/roomstat etc connected what does the system default to?

If it defaults to just looking at flow temp and cyl stat and also the boiler trigger, it would be possible to loop in series the CYL stat connection in the VR66 to the manual timer and the boiler trigger would be that of the CH again to the manual timer?

Ive also seen someone the use the HW valve grey/orange wire as the CYL trigger instead of it currently being tied to the CH valve and triggering the boiler.

Only thing with this method seems to be that it can not do priority by shutting CH unless you give all that control over to the VR66 but if you do it seems that you may have to go full eBUS controls.

https://www.diynot.com/diy/threads/vr65-vr66-for-hw-flow-temp-control.494071/

If none of that is possible ile just dive in and get a eBUS timer and replace all the drayton controls.

Any more info im happy to provide.

Thanks in advance for help.

S-Plan

2 Port HW & CH Valves

Standard HW/CH timer and roomsat/cylstat

Pump 15/50 - Speed 3

ABV installed (setting 2) between pump/valves and return back before the Magnaclean but its on a 15mm not 22mm pipe

10 Radiators (6xType10,2xType20,1xVertical double column, 1xType11

CH Temp 75c

Magnaclean Pro

Old 1910 house with solid walls, insulated loft to 250mm (not in kitchen extension)

Ive got an old thread which was related to this annoying boiler, issues come and go.

https://www.diynot.com/diy/threads/vaillant-418-s53-s7-after-new-radiator.496679/

In recent months as its got colder ive noticed system low firing on S53 especially when HW/CH is being demanded at the same time or when the system starts up from cold, as it gets hot it can go to S07 as the out water temp goes over set point but does not scale back quick enough.

The S07 has been a long standing issue as it can also happen on HW.

Ive scaled back D00 from 16 to 10 and S07 is not such a big problem any more until the whole system comes up to a flow diff temp of about 25c then its rising too much anyway.

Magnaclean has not been too dirty other than when initial powerclean was done back in 2017/18.

Its hard to get the house temp much over 19/20 and takes a long time to get there from cold which based on rad outputs seems to indicate its on the limit of output and will need some rads to be be sized up.

After reading lots of threads im considering the following.

1. The system needs a clean, MC3 etc for a few days, heat exchanger may be sludged then redose MC1

2. Install VR66 to give HW priority control for boiler firing

3. Replace a few of the Type10 radiators for Type 11/21/22 space dependent. They are over 25 years old (when I first moved in, not sure when prior owners had them installed but ile say add another 10 years on that, first powerflush removed tonnes of crud from them). Some places the size makes no sense, ie the hall is huge as it its length of the house and open right to the top but its got a really tiny radiator (7m long, 8m+ to top and 2m wide)

Below is my calculations based on Type10/P1 figures that stelrad show, does not account for age/corrosion/paint emissivity as prior owners have painted rads etc. Silly me its the first time ive actually done the calculation in all these years, I always suspected it was low due to age of house and nearly all type10. The upgrade of one radiator in 2018 actually pushed the BTU up for that room by 2k.

Anyway my real question was, is there any way the VR66 can be used with standard timers or would it need a VRT350/VRC700 to control it.

Its not well documented but if there is no eBUS timer/roomstat etc connected what does the system default to?

If it defaults to just looking at flow temp and cyl stat and also the boiler trigger, it would be possible to loop in series the CYL stat connection in the VR66 to the manual timer and the boiler trigger would be that of the CH again to the manual timer?

Ive also seen someone the use the HW valve grey/orange wire as the CYL trigger instead of it currently being tied to the CH valve and triggering the boiler.

Only thing with this method seems to be that it can not do priority by shutting CH unless you give all that control over to the VR66 but if you do it seems that you may have to go full eBUS controls.

https://www.diynot.com/diy/threads/vr65-vr66-for-hw-flow-temp-control.494071/

If none of that is possible ile just dive in and get a eBUS timer and replace all the drayton controls.

Any more info im happy to provide.

Thanks in advance for help.

Last edited: