Hi All,

I have got an outdoor inflatable jacuzzi. The electric motor that blows the jacuzzi up and creates the bubbles no longer works. It just stopped working the other day and now just makes a click when you switch it on.

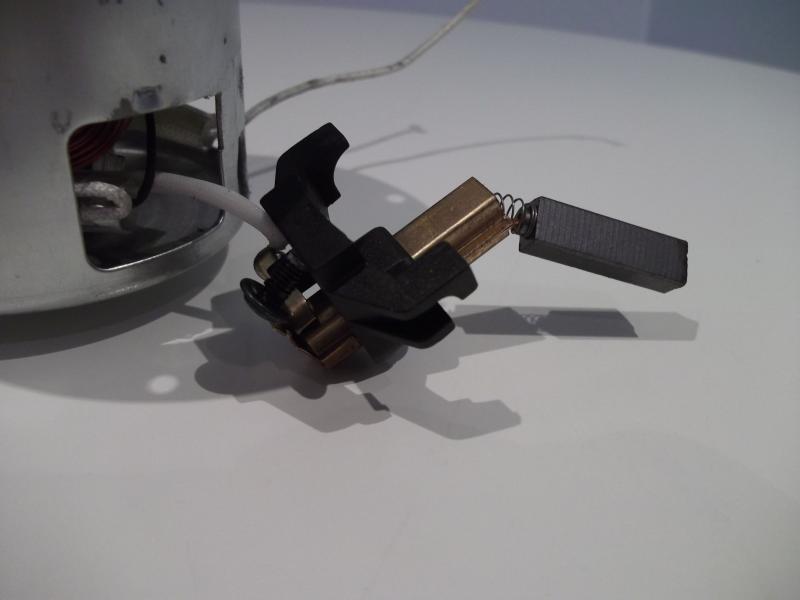

I have tried googling the model of the motor to no avail and contacted the manufacturer to no avail. How easy it is to repair the motor or get a replacement from somewhere? Could it be the brushes?

Its a DS Motor 600watt Motor (230v / 50hz). I have taken it apart, please see the pics:

Thanks for your help!

I have got an outdoor inflatable jacuzzi. The electric motor that blows the jacuzzi up and creates the bubbles no longer works. It just stopped working the other day and now just makes a click when you switch it on.

I have tried googling the model of the motor to no avail and contacted the manufacturer to no avail. How easy it is to repair the motor or get a replacement from somewhere? Could it be the brushes?

Its a DS Motor 600watt Motor (230v / 50hz). I have taken it apart, please see the pics:

Thanks for your help!