Hasn't happened with my MK shower switch in what by now must be tens of thousands of operations.Good work. FYI if you isolate the shower after every use, you may want to consider stopping doing that as is it may be what causes loose connections over a period of time

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electric Shower Help Please.

- Thread starter JBZX

- Start date

- Joined

- 15 Jun 2018

- Messages

- 215

- Reaction score

- 32

- Country

Not saying it's 100% guaranteed to be the cause of every burnt up connection in a shower switch, but I still stand by my advice. If the switch is a bit loose in the ceiling as they sometimes are, pulling that (usually stiff) switch repeatedly every day could certainly cause the connections to loosen over time.Hasn't happened with my MK shower switch in what by now must be tens of thousands of operations.

Isolating the shower after every use isn't really necessary either, most people don't isolate the cooker after every use or a ring final circuit, so why the shower?

I don't know why others do it.

My switch is also functional, which is why it gets used 2-3 times each day.

My switch is also functional, which is why it gets used 2-3 times each day.

You must be really dirty if you need to wash three times a day.I don't know why others do it.

My switch is also functional, which is why it gets used 2-3 times each day.

And what must you be if you decide that that is what must be happening, and not that there's more than one person living here?

LOL. I don't believe that for a second Kevin.And what must you be if you decide that that is what must be happening, and not that there's more than one person living here?

1) You have no grounds for not believing it.

2) Who is Kevin?

3) You really aren't very good at this, are you.

2) Who is Kevin?

3) You really aren't very good at this, are you.

I always thought the reason cookers weren't isolated is because they normally have a clock which needs to be permanently powered to keep time.

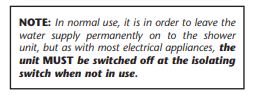

The instructions for most showers however, say something like this example from Triton:

As far as I can remember, none of the shower isolators I have changed have had loose connections, it has been the contacts that have overheated. When operating the shower isolator post showering the contacts won't actually have any current flowing through them at the time, so won't burn or pit from arching at this point. Therefore the damage must occur during the actual usage of the shower.

The instructions for most showers however, say something like this example from Triton:

As far as I can remember, none of the shower isolators I have changed have had loose connections, it has been the contacts that have overheated. When operating the shower isolator post showering the contacts won't actually have any current flowing through them at the time, so won't burn or pit from arching at this point. Therefore the damage must occur during the actual usage of the shower.

I would say that loose connections do cause a lot of the shower isolator burn ups seen, but I don't believe that repeated switching has much of a loosening effect other than where the terminals are not as tight as they should be to start with. If the cores are properly dressed and formed before terminating, the copper strands allowed to relax and settle before nipping up again then there shouldn't be any problems (save from the cases that are down to resistance within the switching contacts).

A lot you see burnt up have clearly had no care taken fitting with conductors forced back into the box, and I'll but they never got nipped up after the conductor was forced right over to one side causing the strands to settle. Granted the crabtree style makes it easier to terminate without forcing stuff back, but it doesn't fix the problem of terminals not being correctly terminated to start with

A lot you see burnt up have clearly had no care taken fitting with conductors forced back into the box, and I'll but they never got nipped up after the conductor was forced right over to one side causing the strands to settle. Granted the crabtree style makes it easier to terminate without forcing stuff back, but it doesn't fix the problem of terminals not being correctly terminated to start with

I always thought the reason cookers weren't isolated is because they normally have a clock which needs to be permanently powered to keep time.

The instructions for most showers however, say something like this example from Triton:

View attachment 155618

As far as I can remember, none of the shower isolators I have changed have had loose connections, it has been the contacts that have overheated. When operating the shower isolator post showering the contacts won't actually have any current flowing through them at the time, so won't burn or pit from arching at this point. Therefore the damage must occur during the actual usage of the shower.

Don't forget manufacturers instructions are guidance only and don't have to be followed especially when they are wrong.

As there is no requirement for a shower isolator in the regs these instructions are clearly wrong.

Don't shoot the messenger. I was just suggesting why people turn off their showers at the isolator. They even print it in bold and tell you it "MUST" be done because its' so important.

Perhaps you should write and tell Triton and (& the others) they are wrong. When you do, please post back, it will be interesting to see their reply

Perhaps you should write and tell Triton and (& the others) they are wrong. When you do, please post back, it will be interesting to see their reply

Last edited:

- Joined

- 28 Apr 2004

- Messages

- 8,381

- Reaction score

- 987

- Country

I would say that loose connections do cause a lot of the shower isolator burn ups seen, but I don't believe that repeated switching has much of a loosening effect other than where the terminals are not as tight as they should be to start with. If the cores are properly dressed and formed before terminating, the copper strands allowed to relax and settle before nipping up again then there shouldn't be any problems (save from the cases that are down to resistance within the switching contacts).

A lot you see burnt up have clearly had no care taken fitting with conductors forced back into the box, and I'll but they never got nipped up after the conductor was forced right over to one side causing the strands to settle. Granted the crabtree style makes it easier to terminate without forcing stuff back, but it doesn't fix the problem of terminals not being correctly terminated to start with

I agree, its a case of the tail wagging the dog sometimes

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 9

- Views

- 3K