Hi all,

First post on here. I am currently having issues trying to wire up a relay for a Garage Door. I can only get the door controls to respond when I press both buttons on at the same time. Below are the details of the relay, garage door PCB and the wiring. If anyone has any ideas, or can point me as to where I am going wrong, it would be much appreciated.

Garage Door: Rollertec v5

- Fitters Handbook (SWS) - LINK

Relay: Shelly Plus 2PM Gen 3

- Vendor specification page - LINK

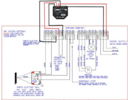

My Wiring

First post on here. I am currently having issues trying to wire up a relay for a Garage Door. I can only get the door controls to respond when I press both buttons on at the same time. Below are the details of the relay, garage door PCB and the wiring. If anyone has any ideas, or can point me as to where I am going wrong, it would be much appreciated.

Garage Door: Rollertec v5

- Fitters Handbook (SWS) - LINK

Relay: Shelly Plus 2PM Gen 3

- Vendor specification page - LINK

My Wiring