Hi,

New to forum, but not DIY however, Electricity is something I rarley deal with other than changing switches for dimmers, light fitting change or the odd double socket spur.

I apologise in advance as this may be a long initial posting - more like bedtime reading!

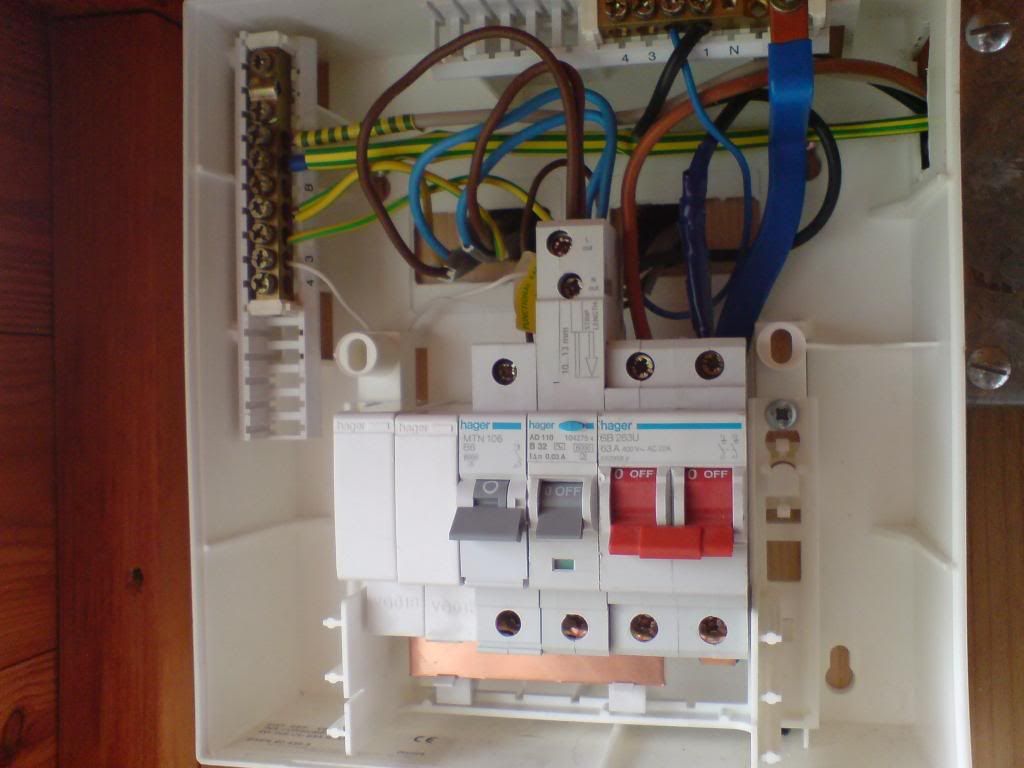

I'm looking to run mains into my 'virgin' concrete section garage (pitched not flat roof) using SWA from main CU to 'garage' CU (MK garage kit RCD [40A 30mA] & 2 X MCBs [16A & 6A], IP65 rated).

From having browsed some of the previous threads, I'm assuming that 6mm 3 core SWA will suffice to feed the garage CU, the armour being terminated [earthed] at house CU end only?. As garage CU is also Poly Carbonate / plastic or similar how / where should the armour be terminated for 'best practice'?

What size MCB should I use in the Main CU to provide for the garage?

I have spare postions.

An underground plastic pipe (25mm water type) exists from near CU location to garage which currently has an extension lead run through to provide temp power. Straight line distance CU to garage 3M approx.

I will also be running in a telephone type cable to extend my alarm system to the garage, can this be run in same pipe?

The garage is / will be a workshop more than some where to store the car (if only I had the room!). Therefore I'm likely to be running power tools eg drills, bench grinders etc as well as having batt chargers etc perm powered. I may also be using arc welding equipment from time to time.

With this in mind I'm planning on installing 4/6 double sockets on a ring, and cabling out in 2.5mm SWA rather than T&E for safety reasons, from the purlings down to the sockets. Am I OK so far or is the SWA overkill for sockets?

Any tips on sockets and their mounting? I was contemplating using steel sockets and screwing direct to concrete rib, 'gently' using SDS drill and rawl plugs (have done drilling before!). Any tips on type of flange to use if at all on the sockets?

I'm unsure what to do re lighting, both type and location, as the roof space is limited as I have wood, pipes, fishing rods, boards etc up there already. I'd thought about using conventional tube lighting with perhaps 2 circuits front / rear of garage (22 ft X 14 ft), switching both from either end of garage as it also has a side door.

Are reinforced enclosures available to prevent tubes being accidentally damaged? 'Normal' Plastic shade type fittings seem a little flimsy for this purpose. I'd though about bulkhead type lights but don't think they'd provide enough illumination without it looking like a string of fairy lights. Any suggestions?

I'm assuming a ring of T&E for the lighting circuits will be ok, 4 core for swicthing but not sure about conductor size.

To the garden - I want to install a spur from the garage to an IP56 switch for a water pump, then continuing on to 2 X single IP56 sockets fastened (sds drill / screwed) to firmly concreted in fence posts at side of small patio area.

The entire run will be paved over, only socket feeds will be above ground from tees below flags. This I'm intending running in SWA 2.5mm 3 core DIG (direct in ground). Any tips on type of flange to use on the IP56 sockets and type on 'tee' junction boxes to use u/g?

I'm also installing a Ring LV lighting system running from transformers which will be plugged into remote controlled sockets located in the garage. The instructions for this lighting says it should 'not be run next to mains' which causes me a problem, how far should these be apart? as the run for the sockets and the LV lighting will be the same from the garage to the end of the socket spur.

Could I use same trench for both?, mains in the bottom covered with warning tape then a layer of soil/hardcore, then plastic conduit above it carrying the LV?

I'm assuming that the mains side of this is reportable?, but don't know how to go about doing so, or how much of the work I am 'legally' allowed to do. I want to do as much as possible myself due to costs, my labour is free! and perhaps call in a sparky to check and connect at the main CU, is this feasible?

Any suggestions or tips would be very much appreciated if I need to change spec on anything please let me know.

Thanks.

New to forum, but not DIY however, Electricity is something I rarley deal with other than changing switches for dimmers, light fitting change or the odd double socket spur.

I apologise in advance as this may be a long initial posting - more like bedtime reading!

I'm looking to run mains into my 'virgin' concrete section garage (pitched not flat roof) using SWA from main CU to 'garage' CU (MK garage kit RCD [40A 30mA] & 2 X MCBs [16A & 6A], IP65 rated).

From having browsed some of the previous threads, I'm assuming that 6mm 3 core SWA will suffice to feed the garage CU, the armour being terminated [earthed] at house CU end only?. As garage CU is also Poly Carbonate / plastic or similar how / where should the armour be terminated for 'best practice'?

What size MCB should I use in the Main CU to provide for the garage?

I have spare postions.

An underground plastic pipe (25mm water type) exists from near CU location to garage which currently has an extension lead run through to provide temp power. Straight line distance CU to garage 3M approx.

I will also be running in a telephone type cable to extend my alarm system to the garage, can this be run in same pipe?

The garage is / will be a workshop more than some where to store the car (if only I had the room!). Therefore I'm likely to be running power tools eg drills, bench grinders etc as well as having batt chargers etc perm powered. I may also be using arc welding equipment from time to time.

With this in mind I'm planning on installing 4/6 double sockets on a ring, and cabling out in 2.5mm SWA rather than T&E for safety reasons, from the purlings down to the sockets. Am I OK so far or is the SWA overkill for sockets?

Any tips on sockets and their mounting? I was contemplating using steel sockets and screwing direct to concrete rib, 'gently' using SDS drill and rawl plugs (have done drilling before!). Any tips on type of flange to use if at all on the sockets?

I'm unsure what to do re lighting, both type and location, as the roof space is limited as I have wood, pipes, fishing rods, boards etc up there already. I'd thought about using conventional tube lighting with perhaps 2 circuits front / rear of garage (22 ft X 14 ft), switching both from either end of garage as it also has a side door.

Are reinforced enclosures available to prevent tubes being accidentally damaged? 'Normal' Plastic shade type fittings seem a little flimsy for this purpose. I'd though about bulkhead type lights but don't think they'd provide enough illumination without it looking like a string of fairy lights. Any suggestions?

I'm assuming a ring of T&E for the lighting circuits will be ok, 4 core for swicthing but not sure about conductor size.

To the garden - I want to install a spur from the garage to an IP56 switch for a water pump, then continuing on to 2 X single IP56 sockets fastened (sds drill / screwed) to firmly concreted in fence posts at side of small patio area.

The entire run will be paved over, only socket feeds will be above ground from tees below flags. This I'm intending running in SWA 2.5mm 3 core DIG (direct in ground). Any tips on type of flange to use on the IP56 sockets and type on 'tee' junction boxes to use u/g?

I'm also installing a Ring LV lighting system running from transformers which will be plugged into remote controlled sockets located in the garage. The instructions for this lighting says it should 'not be run next to mains' which causes me a problem, how far should these be apart? as the run for the sockets and the LV lighting will be the same from the garage to the end of the socket spur.

Could I use same trench for both?, mains in the bottom covered with warning tape then a layer of soil/hardcore, then plastic conduit above it carrying the LV?

I'm assuming that the mains side of this is reportable?, but don't know how to go about doing so, or how much of the work I am 'legally' allowed to do. I want to do as much as possible myself due to costs, my labour is free! and perhaps call in a sparky to check and connect at the main CU, is this feasible?

Any suggestions or tips would be very much appreciated if I need to change spec on anything please let me know.

Thanks.