Hi, Hopefuly someone can offer some advice. I am about to convert part of my garage into a utility/downstairs W.C. The house is a typical late 1940’s semi with a garage on the side. The garage is 9” solid external wall. I propose to take about a third of the existing garage to form the new room, the garage is 2.6m wide and I intend to make the new room 2.2m long. There is a step down from the house to the garage floor (existing floor of garage is concrete and assumed to have no d.p.m) of 230mm falling away to 280mm at the position where the new stud wall will go.

My plan was to take the slope out of the floor with sharp sand and then lay a layer of visqeen with 100mm Celotex on top and 25mm Celotex around the perimeter. On top of the Celotex I will fit a thin layer of polythene (slip layer?) and then pour a 100mm of concrete. I understand that normally a 50mm sand cement screed would be put on top of this but I don’t think I will have the room for this and so wondered if I can just use a thickish self leveller over the concrete? I realise there are ways of using sand and cement down to 25mm by bonding it to the concrete or possibly by adding fibres etc. but as I’m doing it myself I think that I will get a better finish using self leveller (I don’t really have much experience with laying a sand/cement screed and don’t trust my ability).

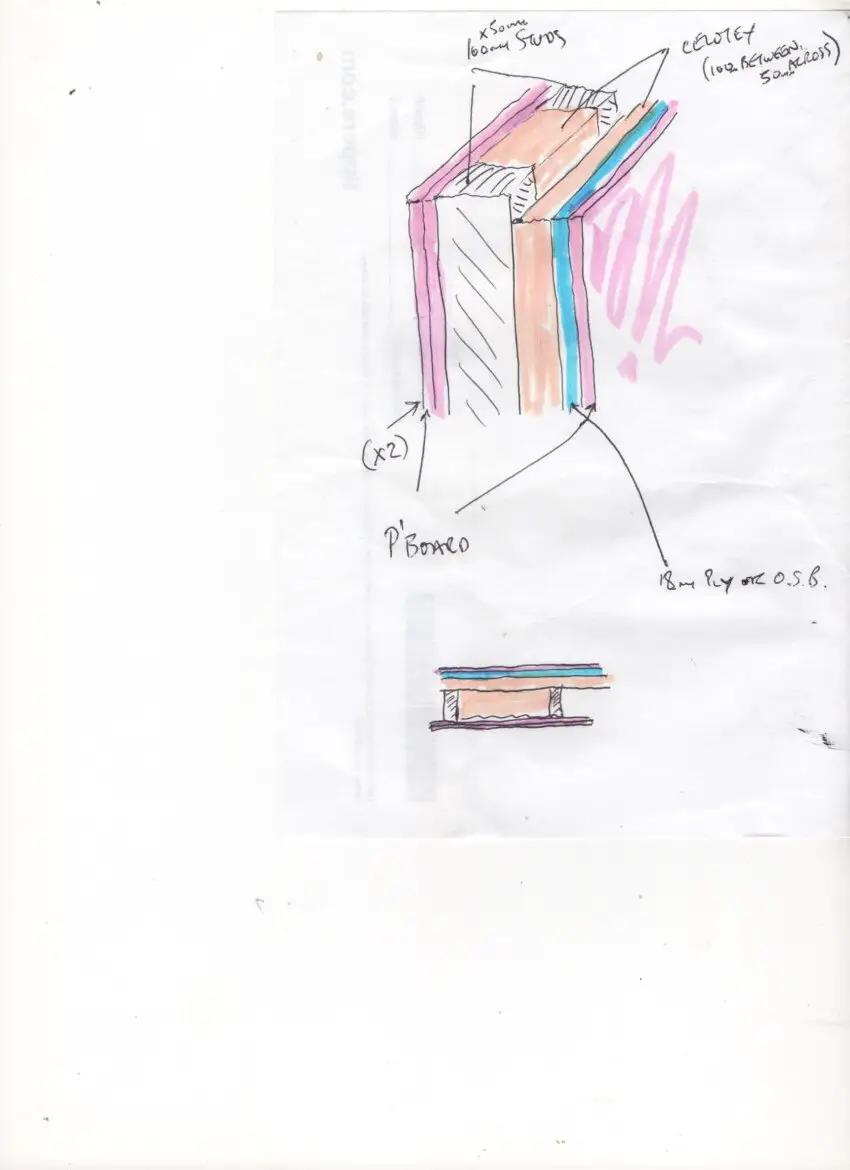

The second question I have is would it be or sensible to build my stud dividing wall first and then fit some ply to the bottom of this to form a shuttering for the new slab or is this not an acceptable way to do things? The alternative would be to form a shuttering across the width of the garage using timber (or brick) approx. 280mm high and then after the floor cures fit the stud wall on top of the floor. The first method just seems more straightforward to me but I just wonder whether it would be acceptable.

I understand I will have to get building control involved at some point but I would like to get things straight in my head before that stage.

Any advice would be very much appreciated.

Thanks.

My plan was to take the slope out of the floor with sharp sand and then lay a layer of visqeen with 100mm Celotex on top and 25mm Celotex around the perimeter. On top of the Celotex I will fit a thin layer of polythene (slip layer?) and then pour a 100mm of concrete. I understand that normally a 50mm sand cement screed would be put on top of this but I don’t think I will have the room for this and so wondered if I can just use a thickish self leveller over the concrete? I realise there are ways of using sand and cement down to 25mm by bonding it to the concrete or possibly by adding fibres etc. but as I’m doing it myself I think that I will get a better finish using self leveller (I don’t really have much experience with laying a sand/cement screed and don’t trust my ability).

The second question I have is would it be or sensible to build my stud dividing wall first and then fit some ply to the bottom of this to form a shuttering for the new slab or is this not an acceptable way to do things? The alternative would be to form a shuttering across the width of the garage using timber (or brick) approx. 280mm high and then after the floor cures fit the stud wall on top of the floor. The first method just seems more straightforward to me but I just wonder whether it would be acceptable.

I understand I will have to get building control involved at some point but I would like to get things straight in my head before that stage.

Any advice would be very much appreciated.

Thanks.