Good morning,

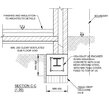

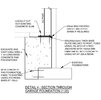

I am just finishing the last of the groundworks for a rear extension. This last stretch requires the installation of a concrete encased universal column to bridge between two padstones (to save excavating down to 2m in medium heave clay).

All appropriate calcs and drawings have been done by my structural engineer however I'm lacking some detail around the practical installation of the steel UC.

The detail shows 155mm celcore beneath the steel, how would you effectively lift the steel above the celcore and suspend it in a manner that won't make it collapse into the cellcore?

I need to speak to the structural engineer about how the steel will interface with the padstone to be poured at the 'southern' end of the steel to ensure their is sufficient support but thought I'd avoid one SFQ by asking you guys N gals for some insight.

Thanks

I am just finishing the last of the groundworks for a rear extension. This last stretch requires the installation of a concrete encased universal column to bridge between two padstones (to save excavating down to 2m in medium heave clay).

All appropriate calcs and drawings have been done by my structural engineer however I'm lacking some detail around the practical installation of the steel UC.

The detail shows 155mm celcore beneath the steel, how would you effectively lift the steel above the celcore and suspend it in a manner that won't make it collapse into the cellcore?

I need to speak to the structural engineer about how the steel will interface with the padstone to be poured at the 'southern' end of the steel to ensure their is sufficient support but thought I'd avoid one SFQ by asking you guys N gals for some insight.

Thanks