It's not as if you weren't told that that would happen....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help wiring an electric motor

- Thread starter threedee

- Start date

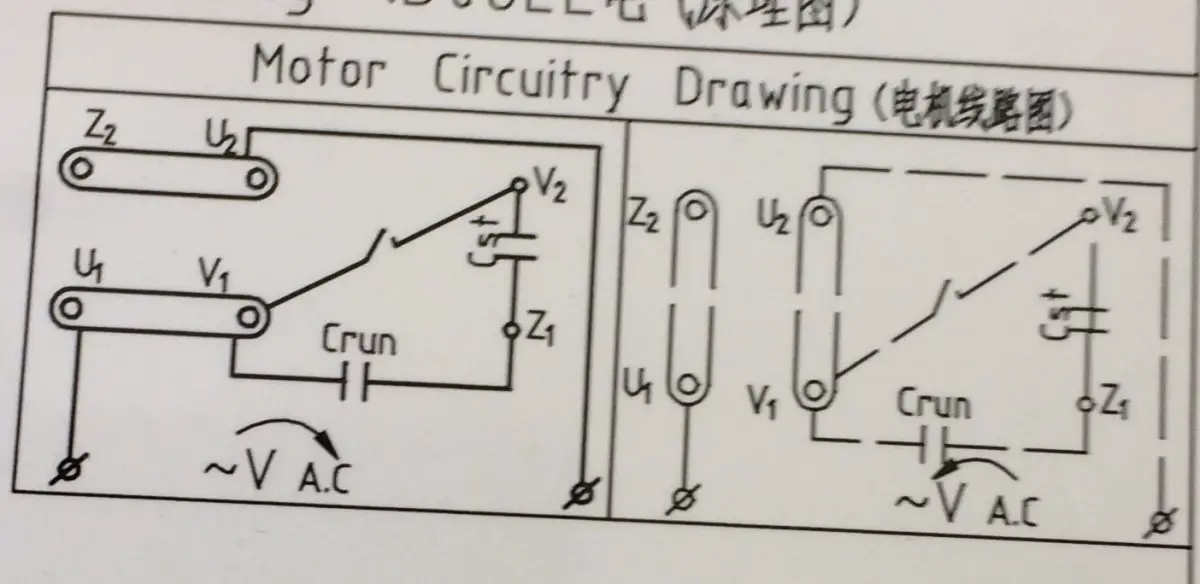

What do we think the TWO devices labelled K are ?

I've tried sketching out what the connections actually work out to in terms of windings, and they just don't make sense to me !

It makes sense for the device connected between V1 and Cst to be a centrifugal switch - just connects additional capacitor during starting for better starting torque.

But what about that switch on the left ?

In the CW setting, it shorts out winding V, leaving winding U across the mains and winding Z in series with the cap(s) across the mains. Once open, then it's winding V in series with the paralleled U and Z windings.

In the CCW setting, winding V is permanently across the mains, windings U and Z are still in parallel (Z in series with the cap(s), but connections reversed) and only supplied with power while K is closed.

Perhaps someone else could try sketching it out, it's just making my head hurt.

I've tried sketching out what the connections actually work out to in terms of windings, and they just don't make sense to me !

It makes sense for the device connected between V1 and Cst to be a centrifugal switch - just connects additional capacitor during starting for better starting torque.

But what about that switch on the left ?

In the CW setting, it shorts out winding V, leaving winding U across the mains and winding Z in series with the cap(s) across the mains. Once open, then it's winding V in series with the paralleled U and Z windings.

In the CCW setting, winding V is permanently across the mains, windings U and Z are still in parallel (Z in series with the cap(s), but connections reversed) and only supplied with power while K is closed.

Perhaps someone else could try sketching it out, it's just making my head hurt.

I'd missed this first time around.You need to change the position of two links between four terminals.

This can not be done with a simple switch. You need to use two interlocked contactors, and some complicated wiring to do this.

Actually it can be done with a fairly simple switch - 2 pole, 2 way, centre off, of an appropriate rating. To be fancy, also add a third pole (make last, break first) so the power can only be applied when the direction is fully established.

If we label the switch as Ac, A1, A2 and Bc, B1, B2 where A,B are the two poles, Ac is common for pole A, and so on ...

Wire Ac to V1 and Bc to Z2.

For CW, A1 to U1 and B1 to U2

For CCW, A2 to U2 and B2 to U1

So for CCW, V1 and U1 are linked, as are U2 and Z2. For CCW, V1 and U2, Z2 and U1 are linked. Matches the wiring diagram as given.

They aren't !

The bare copper will be the remains from where L&N connections were cut off when disconnecting the motor. The V2 and U2 connections (two of the ends for the motor windings) will be well terminated with factory fitted ring terminals.

The bare copper will be the remains from where L&N connections were cut off when disconnecting the motor. The V2 and U2 connections (two of the ends for the motor windings) will be well terminated with factory fitted ring terminals.

Said connections having originally been made by a lazy git who just couldn't be bothered to do it properly.The bare copper will be the remains from where L&N connections were cut off when disconnecting the motor.

I have seen a standard lighting intermediate switch used for reversing this type of motor. It was inside a microswitched cover so the issue of it being changed while the motor was under power didn't exist.

Except that it could be opened, reversed, closed and restarted before the motor had lost much speed and it would shred the belt.

Using a relay I was able to incorporate the centrifugal switch into the starter circuit .

Except that it could be opened, reversed, closed and restarted before the motor had lost much speed and it would shred the belt.

Using a relay I was able to incorporate the centrifugal switch into the starter circuit .

What's the AC3 rating of a standard intermediate switch?

Wasn't able to be switched with the contactor released therefore not used to power the motor on or off, this is a factor I would have checked at the time, it was a small fan, say 1K tops.What's the AC3 rating of a standard intermediate switch?

This is not a kosher arrangement, even though the professional looking diagrams would indicate otherwise.

In CW the windings are in delta formation and in CCW the windings are in star formation, therefore CW and CCW are not equal in terms of torque or performance.

The symbol k normally relates to something thermal, but I'm at a loss as to its purpose.

The motor is not designed to be switched from CW to CCW, and any attempt to defeat this should include a method of changing over only after the motor has been confirmed as stopped. Otherwise there could be a catastrophic accident by the instantaneous change in direction. eg bits of band saw blade flying around.

In CW the windings are in delta formation and in CCW the windings are in star formation, therefore CW and CCW are not equal in terms of torque or performance.

The symbol k normally relates to something thermal, but I'm at a loss as to its purpose.

The motor is not designed to be switched from CW to CCW, and any attempt to defeat this should include a method of changing over only after the motor has been confirmed as stopped. Otherwise there could be a catastrophic accident by the instantaneous change in direction. eg bits of band saw blade flying around.

I believe you have correctly worked that out and no it doesn't make sense.What do we think the TWO devices labelled K are ?

I've tried sketching out what the connections actually work out to in terms of windings, and they just don't make sense to me !

It makes sense for the device connected between V1 and Cst to be a centrifugal switch - just connects additional capacitor during starting for better starting torque.

But what about that switch on the left ?

In the CW setting, it shorts out winding V, leaving winding U across the mains and winding Z in series with the cap(s) across the mains. Once open, then it's winding V in series with the paralleled U and Z windings.

In the CCW setting, winding V is permanently across the mains, windings U and Z are still in parallel (Z in series with the cap(s), but connections reversed) and only supplied with power while K is closed.

Perhaps someone else could try sketching it out, it's just making my head hurt.

I managed to dig out my notes on the motor I described earlier and as far as I can see it is identical

IMG_20170516_0004.pdfPlease excuse the scrappy mess, I may also have photos on an old pc which has given up the ghost.

It seems the 3 windings have the same colour terminations as this one and there are 2 centrifugal switch contacts (all 4 wires black). I used the contact on the left of OP's pic to operate a relay at start-up to prevent starting the fan if the motor was still running.

I can't help thinking the motor windings are not as predicted I do recall it ran very smoothly and quietly but started with a big jerk just as OP mentions.

Attachments

- Joined

- 11 Jan 2004

- Messages

- 46,209

- Reaction score

- 3,652

- Country

This is not a kosher arrangement, even though the professional looking diagrams would indicate otherwise.

So I'm not alone in thinking there's something very odd about the wiring for this motor.I believe you have correctly worked that out and no it doesn't make sense.

That's one of the effects of having a start cap - the increase in starting torque also means a bigger jerk on starting.... I do recall it ran very smoothly and quietly but started with a big jerk just as OP mentions.

I'm trying to clear out a load of old paperwork and checking it all before it goes into the big green bin.

Came across another of these motors. Again it appears to be the same and has the benefit of windings resistance listed.

This one is/was a roller shutter door operated by 3 contactors, the 'K' contact appears to have been replaced with a timer and a second timer prevents it being restarted too quickly by the look of it.

Apologies for my illegible scrawl.

Came across another of these motors. Again it appears to be the same and has the benefit of windings resistance listed.

This one is/was a roller shutter door operated by 3 contactors, the 'K' contact appears to have been replaced with a timer and a second timer prevents it being restarted too quickly by the look of it.

Apologies for my illegible scrawl.

Attachments

My motor is Single phase ML8022 1.1kW. Here is wiring of my motor: Black (U1 and U2), Yellow (V1 and V2), Red (Z1 and Z2), and two white wires with no marking, which i tested and they are short circuited. All wires are 0,5mm2. I do not know the purpose of these white wires and could not find explanation. It is centrifugal switch or thermal contact i.e. PTC? I attached schematic. There are contact between V1 and V2. Can anyone give me explanation what is this contact and how to connect it. Maybe it is internal in motor and it is not necessary to connect this contact?

I have tried to connect white wires between V1 and V2, but motor current draws ~30A and it worked loudly and noisy.

I have tried to connect white wires between V1 and V2, but motor current draws ~30A and it worked loudly and noisy.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 3

- Views

- 2K