- Joined

- 21 Dec 2017

- Messages

- 249

- Reaction score

- 48

- Country

Hi all,

In searching for an answer myself I noticed that DIY cutting of larger tiles is a consistent question on this forum, especially when it’s on the diagonal, as you need a large (and expensive) cutter to do this. e.g. for 600 x 600 tiles, to cut corner to corner for a shower/wetroom floor envelope cut, you need a cutting length of nearly 850mm and really you need to remove material between the two halves to leave a grout gap, which obviously even the most high end score n snap wouldn’t give you. So you’d need to buy or hire a very large bridge type wet cutter.

Failing that people usually suggest ‘get an expensive diamond blade and dry cut it freehand with an angle grinder’ but in doing that you have a number of very significant challenges:

1 - Keeping your cut line straight

2 - Keeping your cut square to the surface

3 - Keeping your fingers attached to your hands

4 - Avoiding chips and broken off corners

5 - Inhalation of the large cloud of silica dust that will be generated

Here's how I managed this challenge at minimal cost on my own project which I tiled with envelope cut 600 x 600 porcelain tiles and achieved a near-flawless DIY finish.

For my cheap green Bosch grinder, Bosch produce a £24 optional add-on cage and guide, part number 2605510292.

My model grinder PWS850-125 is not actually listed as compatible with it but whether that’s just because it’s not a currently produced model I don’t know - but I expect any Bosch grinder with this twist-on toothed guard interface would work. There’s also another version that looks like it has a more universal clamp on collar type deal. I sealed the extraction hole with duct tape.

I used a cheap (£8) bosch ‘ceramic’ continuous rim diamond blade.

So, even if you don't already have a grinder you can fit one of these guides to or are starting from nothing, you can get everything you need for about £80.

You just clamp a straight edge (I used a piece of 20mm square ally extrusion) to your tile and run the grinder guide along that to guarantee a perfectly straight cut, while the guide keeps the cut square to the surface. So that’s problems 1, 2 and 3 sorted. But it still chips quite a bit and makes clouds of nasty dust.

Having an assistant use a small trigger spray bottle to spray water at the blade while you cut completely solves those two issues. Obviously there is a risk involved with doing this and you should impress upon your assistant that they must keep their water spray confined to the blade, not your hands or the grinder. In practice, you don’t actually need to spray that much water and because of the guard I found that my hands and the grinder body remained basically bone dry throughout. But test your RCD before you start anyway

Do a trial cut first to get the blade offset - clamp your straight edge arbitrarily to a tile and cut it, then with a steel rule or even a vernier caliper, you can measure a precise distance between your guide bar and the cut edge - you can then use this measurement to position your guide bar extremely precisely each time for your proper cuts. Sounds like a faff but it’s really no more than 30 seconds set up for each cut. You can cut to 0.5mm or better precision like this. Really.

Make each cut in more than one pass, the first one being quite shallow. If you try to cut in one pass, you’ll usually get small chips (like a normal wet cutter) but worse than that, the tile will break when you get near the end of the cut and usually not where you want it to.

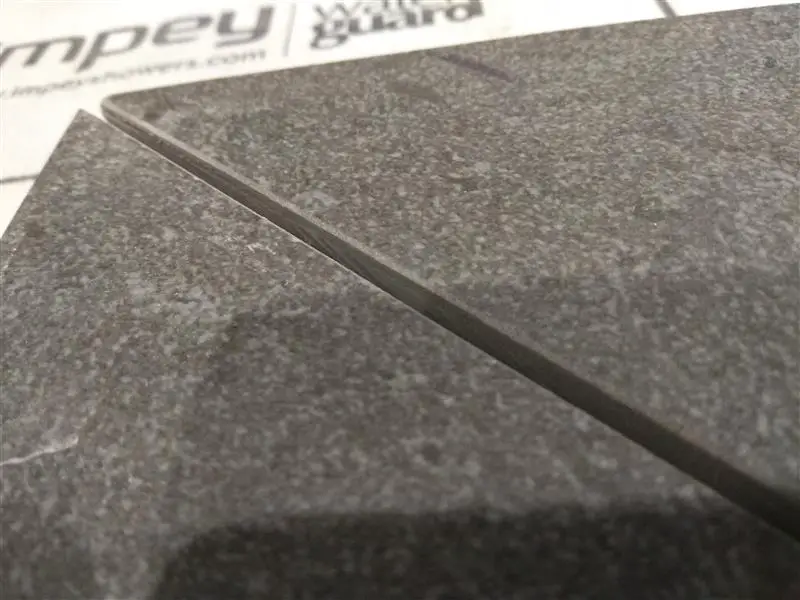

Doing it this way I consistently cut porcelain absolutely dead straight and square with no chips, a cut edge essentially indistinguishable from the factory rectified edges and perfectly intact 45 degree corners at both ends. You can even use this method to shave small amounts cleanly and accurately off the edge of a tile.

A quick rub back with a diamond pad on the edge of your new cut to replicate the factory edge bevel, and job’s a good ‘un.

Yeah, I’m sure lots of people will claim they can freehand dry cut and achieve a similar result, but for me this was a game changer. Hope it’s helpful to someone else.

Here’s my finished shower floor. This is the first bit of tiling I’ve ever done. 'Scuse the grout haze...

In searching for an answer myself I noticed that DIY cutting of larger tiles is a consistent question on this forum, especially when it’s on the diagonal, as you need a large (and expensive) cutter to do this. e.g. for 600 x 600 tiles, to cut corner to corner for a shower/wetroom floor envelope cut, you need a cutting length of nearly 850mm and really you need to remove material between the two halves to leave a grout gap, which obviously even the most high end score n snap wouldn’t give you. So you’d need to buy or hire a very large bridge type wet cutter.

Failing that people usually suggest ‘get an expensive diamond blade and dry cut it freehand with an angle grinder’ but in doing that you have a number of very significant challenges:

1 - Keeping your cut line straight

2 - Keeping your cut square to the surface

3 - Keeping your fingers attached to your hands

4 - Avoiding chips and broken off corners

5 - Inhalation of the large cloud of silica dust that will be generated

Here's how I managed this challenge at minimal cost on my own project which I tiled with envelope cut 600 x 600 porcelain tiles and achieved a near-flawless DIY finish.

For my cheap green Bosch grinder, Bosch produce a £24 optional add-on cage and guide, part number 2605510292.

My model grinder PWS850-125 is not actually listed as compatible with it but whether that’s just because it’s not a currently produced model I don’t know - but I expect any Bosch grinder with this twist-on toothed guard interface would work. There’s also another version that looks like it has a more universal clamp on collar type deal. I sealed the extraction hole with duct tape.

I used a cheap (£8) bosch ‘ceramic’ continuous rim diamond blade.

So, even if you don't already have a grinder you can fit one of these guides to or are starting from nothing, you can get everything you need for about £80.

You just clamp a straight edge (I used a piece of 20mm square ally extrusion) to your tile and run the grinder guide along that to guarantee a perfectly straight cut, while the guide keeps the cut square to the surface. So that’s problems 1, 2 and 3 sorted. But it still chips quite a bit and makes clouds of nasty dust.

Having an assistant use a small trigger spray bottle to spray water at the blade while you cut completely solves those two issues. Obviously there is a risk involved with doing this and you should impress upon your assistant that they must keep their water spray confined to the blade, not your hands or the grinder. In practice, you don’t actually need to spray that much water and because of the guard I found that my hands and the grinder body remained basically bone dry throughout. But test your RCD before you start anyway

Do a trial cut first to get the blade offset - clamp your straight edge arbitrarily to a tile and cut it, then with a steel rule or even a vernier caliper, you can measure a precise distance between your guide bar and the cut edge - you can then use this measurement to position your guide bar extremely precisely each time for your proper cuts. Sounds like a faff but it’s really no more than 30 seconds set up for each cut. You can cut to 0.5mm or better precision like this. Really.

Make each cut in more than one pass, the first one being quite shallow. If you try to cut in one pass, you’ll usually get small chips (like a normal wet cutter) but worse than that, the tile will break when you get near the end of the cut and usually not where you want it to.

Doing it this way I consistently cut porcelain absolutely dead straight and square with no chips, a cut edge essentially indistinguishable from the factory rectified edges and perfectly intact 45 degree corners at both ends. You can even use this method to shave small amounts cleanly and accurately off the edge of a tile.

A quick rub back with a diamond pad on the edge of your new cut to replicate the factory edge bevel, and job’s a good ‘un.

Yeah, I’m sure lots of people will claim they can freehand dry cut and achieve a similar result, but for me this was a game changer. Hope it’s helpful to someone else.

Here’s my finished shower floor. This is the first bit of tiling I’ve ever done. 'Scuse the grout haze...

Last edited: