RMS said:

from an electrical safety point of veiw can you explain why the earth wire in a circuit is normally smaller and of higher resistance than the live conductors?

Simple.

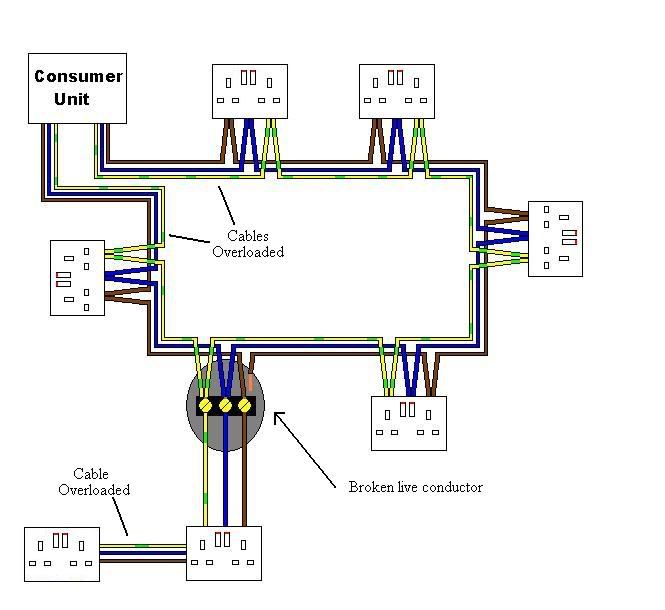

The live and neutral conductors are designed to theire rated load continually. So for example if you have a 2.5mm² t+e installed to reference method 3 it will happily carry 23A for 24 hours a day without getting hot and causing problems by being overloaded.

The earth conductor is smaller and has a slightly higher resistance because it is, to give it it's proper name, a Circuit Protective Conductor (cpc).

The only time this wire will be carrying any real current* is in the event of a fault such as a short circuit from live to earth, where both the live and earth will be carrying sometimes as much as 2000A but this high current will cause the Over Current Protective Device (fuse / mcb) to operate therefore removing the power. This is why your zs must be low enough for the type of ocpd that is protecting the circuit, (see appendix 2 of the OSG) so that the current will be cut within a maximum of 5 seconds.

The lower the value of Zs, the more current will flow in the event of a fault, and the quicker the OCPD will operate.

So in summary the earth is smaller as it is designed to carry current for a very short amount of time (max 5 secs) in the event of a fault, whereas the live and neutral are designed for carrying current all the time.

*the earth will be carying a little current all the time, but it will only be earth leakage from appliances, and will be only a few mA.

There is nothing wrong with cutting the earth wire as long as you maintain the mechanical connection and coninuity whch is proven on testing and inspection of the circuirt.

RMS

There is nothing wrong with cutting the live or neutral either.