You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LED to monitor motor

- Thread starter Marnhullman

- Start date

Another one.

I have to agree with both of these statements as in some water pumps there is no mechanical connection between the impeller & the rotorI would say that's actually the best solution - since, in the final analysis it is presumably water flow which actually matters to the OP.

One can (despite winston's attempt to confuse) use electrical methods to detect whether or not the pump motor is running fairly normally but, at least in theory, the fact that a pump's motor is functioning normally does not guarantee that water is being pumped satisfactorily (anywhere, or to where it is meant to be being pumped).

Kind Regards, John

( not sure if this is the type the op. has ) so the impeller jamming or getting blocked could not give any indication that there was a problem.

- Joined

- 31 Dec 2003

- Messages

- 179

- Reaction score

- 1

- Country

Thanks for the feedback - I think!

The treatment plant has an air pump not a water pump so perhaps some of the solutions may not be effective?

I had thought of using some sort of current monitor but I guess that would need a separate cable which is not practicable. Think I'll just have to ensure I monitor the unit manually.

The treatment plant has an air pump not a water pump so perhaps some of the solutions may not be effective?

I had thought of using some sort of current monitor but I guess that would need a separate cable which is not practicable. Think I'll just have to ensure I monitor the unit manually.

- Joined

- 31 Dec 2003

- Messages

- 179

- Reaction score

- 1

- Country

Should have mentioned that there's a sacrificial pin that breaks in the event either of the air pump diaphragms break. The pump then stops. On the occasion this happened recently the circuit was tripped but whether that would always happen I don't know.

Ah! Well, I suppose you could just read the 'flow sensor' I suggested as meaning 'air flow', rather than 'water flow' - but suitable sensors might not be quite so easy to find. However, given ...The treatment plant has an air pump not a water pump so perhaps some of the solutions may not be effective?

it sounds as if you could not contemplate any sort of remote sensor.I had thought of using some sort of current monitor but I guess that would need a separate cable which is not practicable.

Do you mean that the pump is then switched off (electrically)? If so, the disappearance of current being drawn could certainly be sensed 'at the other end'.Should have mentioned that there's a sacrificial pin that breaks in the event either of the air pump diaphragms break. The pump then stops.

Kind Regards, John

- Joined

- 27 Jan 2008

- Messages

- 27,722

- Reaction score

- 3,363

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

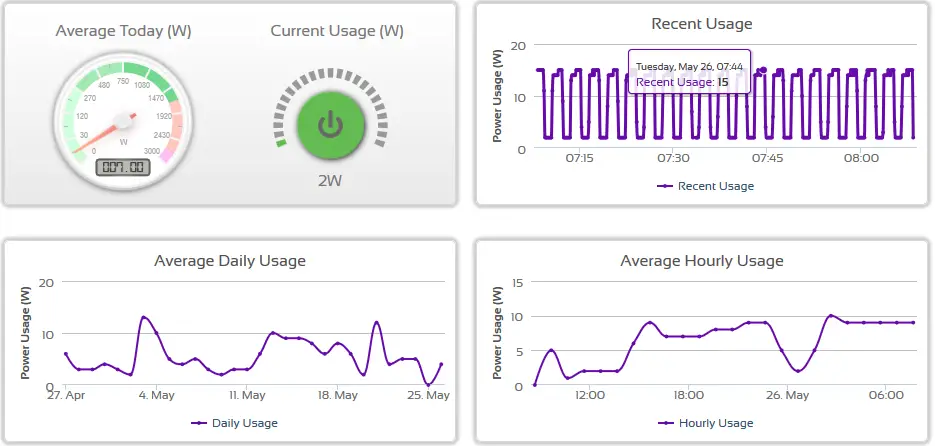

I did design some thing similar to switch to a spare extractor fan and turn off the plant should both fail, as long as the motor has an overload that will open if the motor stalls, then the current monitoring only needs to be on/off, however today I use battery chargers, air conditioning units, and all sorts of other equipment where I want to monitor what is going on. I use one of these

may be not the best one for you, but for me it means a very easy method of seeing what is going on from my bedroom so at the moment I am charging a battery together with other devices when starting firefox I see

may be not the best one for you, but for me it means a very easy method of seeing what is going on from my bedroom so at the moment I am charging a battery together with other devices when starting firefox I see

and clicking on monitor with other bits I get this

and clicking on monitor with other bits I get this

As a result I can work out what has happened, there are IFTTT options to set alerts so I could set an alarm, the patterns shown don't matter, but clearly you would know the normal power used and would see by using a web browser if it is using normal amount of power, at the moment I have a sulphated battery being charged, when the charge rate drops to zero I will know it has recovered.

As a result I can work out what has happened, there are IFTTT options to set alerts so I could set an alarm, the patterns shown don't matter, but clearly you would know the normal power used and would see by using a web browser if it is using normal amount of power, at the moment I have a sulphated battery being charged, when the charge rate drops to zero I will know it has recovered.

In your case if the pump gets dirty likely the power used will climb showing it needs cleaning, it would show very high if stalled, and too low if a shaft breaks etc, and very quickly you would get to know the normal use.

I also have an old meter given free by Scottish power some years ago which measures power used but does not record, I noted this

at £12.47 again may be not idea as need mounting in something, but it would show power being used, and so show both over and under current. I would not think your system would not have an overload which would trip on stalling, many overloads have aux contacts to allow fitting a light or buzzer once triggered, in other words there are many ways to monitor, but since it would be good to see some thing before it fails, the ammeter is likely the best option.

at £12.47 again may be not idea as need mounting in something, but it would show power being used, and so show both over and under current. I would not think your system would not have an overload which would trip on stalling, many overloads have aux contacts to allow fitting a light or buzzer once triggered, in other words there are many ways to monitor, but since it would be good to see some thing before it fails, the ammeter is likely the best option.

In your case if the pump gets dirty likely the power used will climb showing it needs cleaning, it would show very high if stalled, and too low if a shaft breaks etc, and very quickly you would get to know the normal use.

I also have an old meter given free by Scottish power some years ago which measures power used but does not record, I noted this

he treatment plant has an air pump not a water pump

I guess this is an aerobic system with the pump pumping air into bottom of the aerobic digester. If that is the case then a simple air pressure switch ( with a change over switch contact ) tee'd into the pipe from the pump should provided reliable loss of pumping.

Then how to get the signal from the senor to the house ? Would an audible alarm be OK ? That would avoid the need to install an alarm cable from pump to house and effective is raising the alarm.

Many packaged digester systems include this loss of air pressure alarm as standard

As Bernard said...using the air pressure might be the simplest method.

Knock up a simple water gauge (manometer) to measure the air pressure (and to see whether it fluctuates and may require damping).

Then use an adjustable air pressure switch (eg. look at Honeywell or Huba often used in boilers).

The appropriate APS contacts could switch on a flashing Led mounted such that it could be seen with a quick glance at night.

Alkaline batteries would be long lasting.

Knock up a simple water gauge (manometer) to measure the air pressure (and to see whether it fluctuates and may require damping).

Then use an adjustable air pressure switch (eg. look at Honeywell or Huba often used in boilers).

The appropriate APS contacts could switch on a flashing Led mounted such that it could be seen with a quick glance at night.

Alkaline batteries would be long lasting.

Such as this company: https://www.ecproducts.co.uk/product/air-differential-pressure-switch-50-500pa-930-83/As Bernard said...using the air pressure might be the simplest method.

Knock up a simple water gauge (manometer) to measure the air pressure (and to see whether it fluctuates and may require damping).

Then use an adjustable air pressure switch (eg. look at Honeywell or Huba often used in boilers).

The appropriate APS contacts could switch on a flashing Led mounted such that it could be seen with a quick glance at night.

Alkaline batteries would be long lasting.

For once, your guess was imperfectI'm guessing the OP has long gone.....

Kind Regards, John

- Joined

- 31 Dec 2003

- Messages

- 179

- Reaction score

- 1

- Country

Ummmmh. 'Knock up a simple manometer...' The solutions all sound fascinating and I've got time on my hands at the moment but I'm just a DIYer with no electrical training. I was really hoping for a simple plug in device but that doesn't seem possible.

I'll mull over the suggestions and try to figure out if I'm up to the job!

Thanks for the replies.

I'll mull over the suggestions and try to figure out if I'm up to the job!

Thanks for the replies.

I would suggest that you should probably start by deciding exactly what 'failure mode(s)' you want to be able to detect (pump motor failure, blocked/broken/leaking air lines, inadequate air pressure etc. etc.) and then work from there.Ummmmh. 'Knock up a simple manometer...' The solutions all sound fascinating and I've got time on my hands at the moment but I'm just a DIYer with no electrical training. I was really hoping for a simple plug in device but that doesn't seem possible. I'll mull over the suggestions and try to figure out if I'm up to the job!

One over-riding issue you're likely to have is that almost any remote sensing would require some sort of connection back to your house and if, as you say, additional cables are not a possibility, some sort of wireless connection would probably be the only option, which would increase complexity (and cost). Per you original question/suggestion, without additional cables (or other means of communication) all you could possibly monitor would be the current (if any) being drawn by the pump motor - and, as has been said, that could not reliably detect all of the possible things that could 'go wrong'.

Kind Regards, John

Ummmmh.I'm just a DIYer

What sort of attitude is that

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 7

- Views

- 14K