I want to replace my old skinny insulation and find that most insulation rolls are either 370 or 400mm width but the width between my joists are 390 do I go for 400 and squeeze it in or have 10mm space either side also the depth is 100mm if I use 100mm roll can I put boards back on top

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Loft insulation width problem

- Thread starter bobajob100

- Start date

Sponsored Links

Use 400mm and don't compress the insulation as it becomes less efficient.

250mm is the required (b'regs) minimum. 100mm between the joists and 150mm at 90 degrees across the joists.

If you want to board the loft you need to either rethink your insulation strategy or prioritise as to whether space is more important than insulation.

250mm is the required (b'regs) minimum. 100mm between the joists and 150mm at 90 degrees across the joists.

If you want to board the loft you need to either rethink your insulation strategy or prioritise as to whether space is more important than insulation.

thanks, I am getting a little confused by looking at all the problems people are having with the boarding problem. If I put 100mm insulation in between the joists which is their depth would it be much of a problem with any condensation as the boards would just be touching and not compressing the insulation. This would give me 100mm of insulation which is three times the amount I have at the moment with the skinny remains of the old stuff How efficient would this be, I know it is not the recommended thickness of 250 but there are differing opinions on the forums about needing so much

100mm will obviously be less insulating that 250mm but better than what you've got. 100mm insulation between the ceiling and the boards will be fine. I concur that around 250mm is the current required thickness. 100mm quilt type insulation would have no chance of complying with the latest regs. If you went with a rigid (but more expensive) type of insulation like Kingspan that would get you closer to the target values.

Sponsored Links

...recommended thickness of 250 but there are differing opinions on the forums about needing so much

Any contrary opinion is wrong. The minimum U-value for a pitched roof insulated at ceiling level is 0.16W/m²K. To achieve that you will need a minimum of 250mm mineral wool.

However, building regs do not apply to straightforward replacement or adding more insulation to an existing loft. So you can fit what you want - or what you physically can is probably more sensible. (don't go too mad though. The law of diminishing return applies.)

Condensation is a potential problem. If you pack the gap between ceiling and underside of the loft board you will most likely cause condensation. If you have no alternative I would advise leaving the boards loose and checking the underside occasionally.

I've had this exact situation in my loft for 9 years and have occasionaly had the need to lift the boards and there's been no evidence of condensation.If you pack the gap between ceiling and underside of the loft board you will most likely cause condensation. If you have no alternative I would advise leaving the boards loose and checking the underside occasionally.

Condensation or the conditions that allow it to occur, can differ from house to house in the same street.

For the first couple of years, in my own home there was little insulation AND the loft was partially boarded. No prob's with condensation. Yet the next door but one has problems with condensation forming on their roof membrane. Ho hum.

The idiosyncratic nature of condensation can be mostly accounted for if full b'regs specifications are applied. But there are no guarantees.

For the first couple of years, in my own home there was little insulation AND the loft was partially boarded. No prob's with condensation. Yet the next door but one has problems with condensation forming on their roof membrane. Ho hum.

The idiosyncratic nature of condensation can be mostly accounted for if full b'regs specifications are applied. But there are no guarantees.

My neighbour asked me to look at his roof several months back because he had moved a whole load of cardboard boxes from his loft and as he was lifting the boxes the bottoms were falling out because they were sodden with damp. I cleared my own loft completely last year for a loft conversion and boxes which had been there for 20 years were perfect.

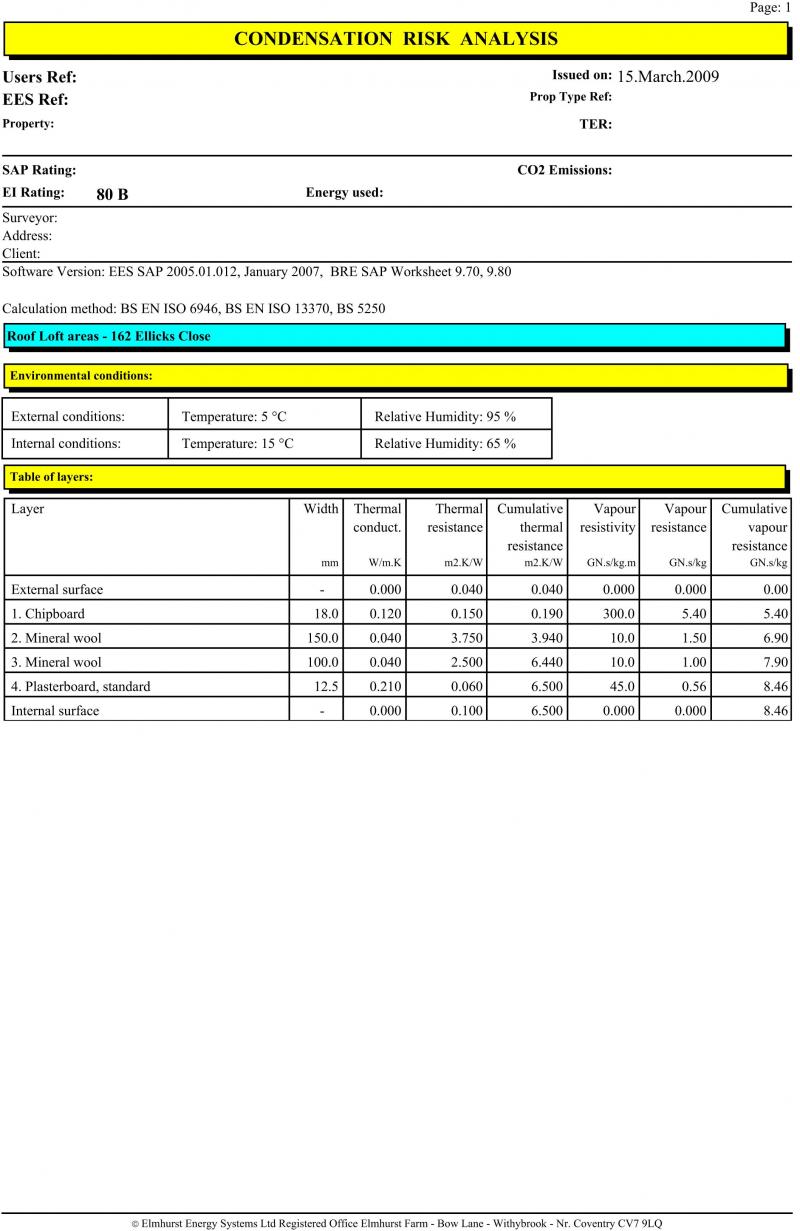

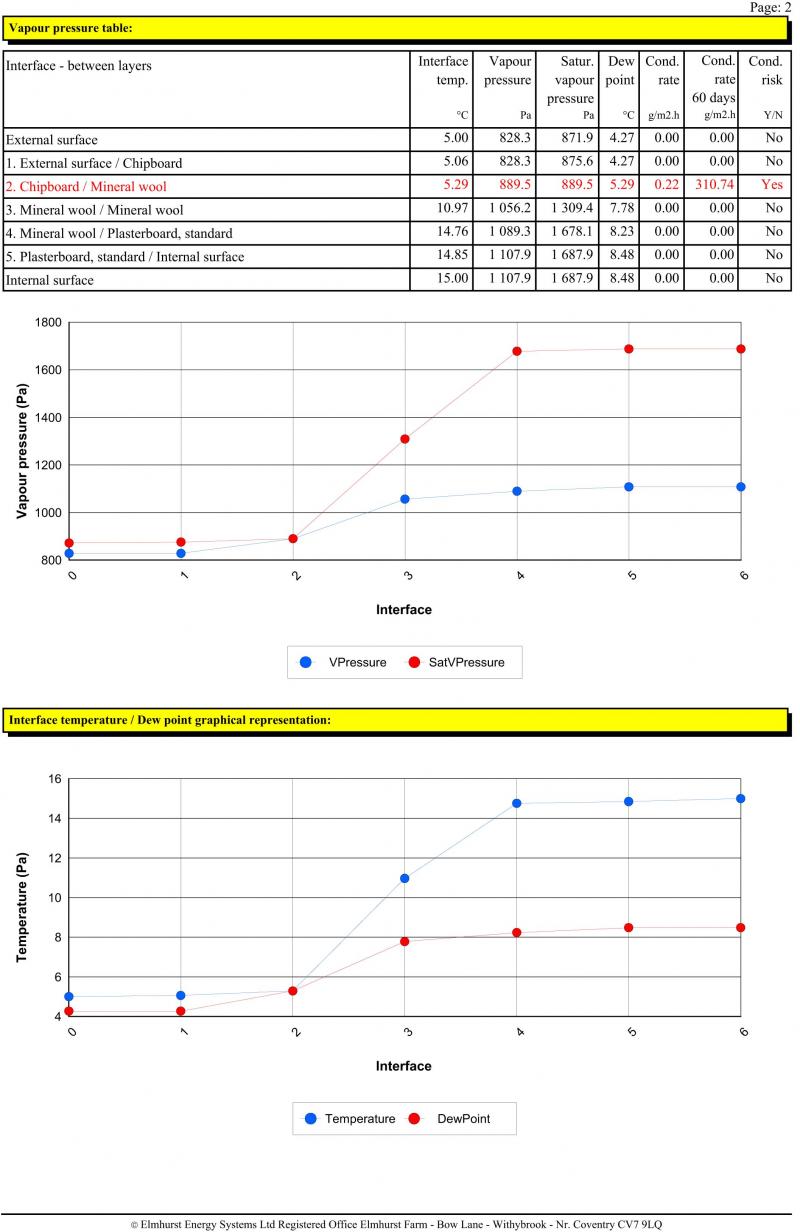

What I do know for sure is that if you run a condensation risk analysis on a boarded loft with enclosed insulation it will definitely fail.

What I do know for sure is that if you run a condensation risk analysis on a boarded loft with enclosed insulation it will definitely fail.

What I do know for sure is that if you run a condensation risk analysis on a boarded loft with enclosed insulation it will definitely fail.

A fairly sweeping statement, but i can not disagree none the less. How is the risk analysis carried out?

Very impressive stuff, so are you saying that if I use 100mm incapsulated fiber insulation in my 100mm depth joists and cover it with boarding I will get Condensation.

...on paper.I opened a previous loft calc and added a ceiling board to see what happens. It failed.

Is there no physical/practical test then? Does the test take into consideration vapour barriers or lifestyle or amount of occupants?

Very impressive stuff, so are you saying that if I use 100mm incapsulated fiber insulation in my 100mm depth joists and cover it with boarding I will get Condensation.

As previously mentioned, there are other factors involved and condensation will sometimes occur and other times not. My advice is leave some boards unfixed and lift them occasionally to see if a problem develops. It's not ideal but preferable to having just a 50mm layer of insulation

Noseall, the calculation is based on standard parameters, which is why you are right in saying some people will get condensation and others not. In reality few of us actually fit those standard round holes. A vapour barrier would also make a difference but that's obviously only practical for new build.

Remember, I didn't say the calculation was gospel. I originally said that the situation of enclosed mineral wool insulation against an unvented cold surface (the underside of the chipboard) is likely to cause condensation. That's not a guess or a sweeping statement out of the blue - it's an opinion based on some knowledge of construction technology and environmental science. I then said that a standard risk analysis would definitely show that condensation will occur - which it does.

Thank you John,I know this seems a daft question but having never seen what condensation looks like in unsulation what would I expect to find when I lift the boards if there was condensation.

i said that a standard risk analysis would definitely show that condensation will occur - which it does.

Cheers John.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 1

- Views

- 774

- Replies

- 2

- Views

- 2K