I have argued about this with my son, Father-in-law was electrician, father was in charge of a power station, I am an electrician, my son is an electrician, my son-in-law did an electrical and electronics degree so in real terms non of us live in a house under the control of an ordinary person so any coding would have to show what the code says.

So only code could be for "Improvement Recommended" i.e. C3 and the question is would improvement contribute to a Significant enhancement of the safety of the electrical installation. So can't really see how it can be coded.

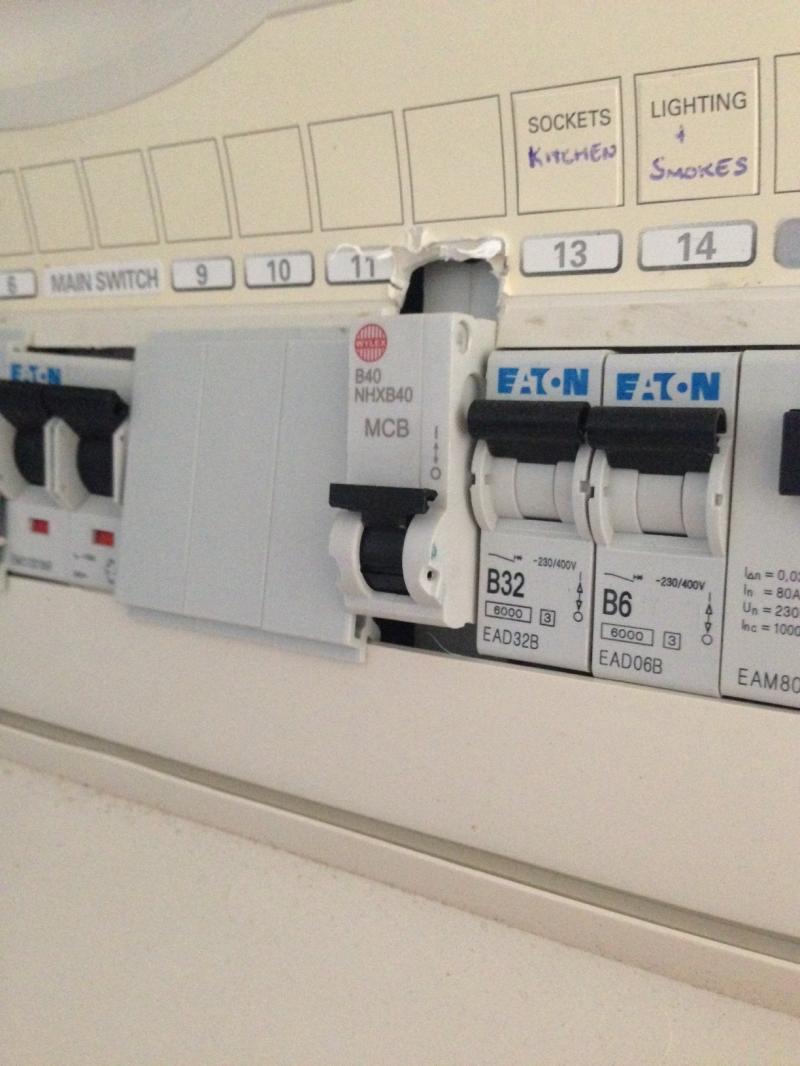

There are cases like in the picture where some modification has been done. However even in the picture it is not plain to if the IP rating has been compromised or not. The real danger is not where we can see, but where without trying to remove the MCB you are really unaware if it is placing undue strain on the buzz bar and could that strain cause a false impression as to if there is a good connection on either the replacement or existing MCB's.

Main reason for me to fail a consumer unit is being able to remove the blanks without a tool. I see the Best Practice Guide does have some items I would not agree with. For example an immersion heater without a thermal cut-out is only a danger when the header tank is made from a thermal plastic, the header tanks designed for use with solid fuel heating will not fail if either the electric or solid fuel heat source was to cause the water to boil so it presents no danger.

This however raises the question is an electrician qualified to comment on non electrical danger if the under floor heating can heat the floor to over 55°C it does not comply with regulations, but most electricians would not even test to find if it complies or not.

If you find an item plugged into a socket which is not to the British Standard is that included? Should you give a C3 because there is a silly socket protector plugged into the socket? Or when still under the control of the builder do you C3 extension leads going to quartz lamps used to dry the plaster?

To put a note bundled with the report saying the consumer unit has a mixture of MCB's which could adversely effect their operation and you would suggest this is rectified is OK, putting in the report is going OTT.