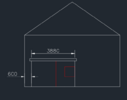

I'm having a new RSJ put in (blue) to remove a wall (red). To reduce the work the beam is going beneath a steel lintel (green) already in place.

The best approach seems to be up for deliberation so I thought I'd see what other opinions and ideas are out there...

1. jack the new RSJ against the existing beam. Then jack the padstones up and fill underneath with mortar. Given the padstones take the weight this seems the most risky, it assumes the mortar doesn't shrink when set etc.

2. try and pack the gap using layers of thin steel, say 0.5mm. Might still have movement when the props are removed.

3. weld the sides of the RSJ/lintel together, possibly along with (2).

4. inject the gap, possibly some sort of epoxy? This would ensure the gap is filled. Please, don't suggest expanding foam.

IMO (4) is the best option. I'll be asking the structural engineer later on as well

Cheers!

The best approach seems to be up for deliberation so I thought I'd see what other opinions and ideas are out there...

1. jack the new RSJ against the existing beam. Then jack the padstones up and fill underneath with mortar. Given the padstones take the weight this seems the most risky, it assumes the mortar doesn't shrink when set etc.

2. try and pack the gap using layers of thin steel, say 0.5mm. Might still have movement when the props are removed.

3. weld the sides of the RSJ/lintel together, possibly along with (2).

4. inject the gap, possibly some sort of epoxy? This would ensure the gap is filled. Please, don't suggest expanding foam.

IMO (4) is the best option. I'll be asking the structural engineer later on as well

Cheers!