- Joined

- 2 Mar 2023

- Messages

- 11

- Reaction score

- 0

- Country

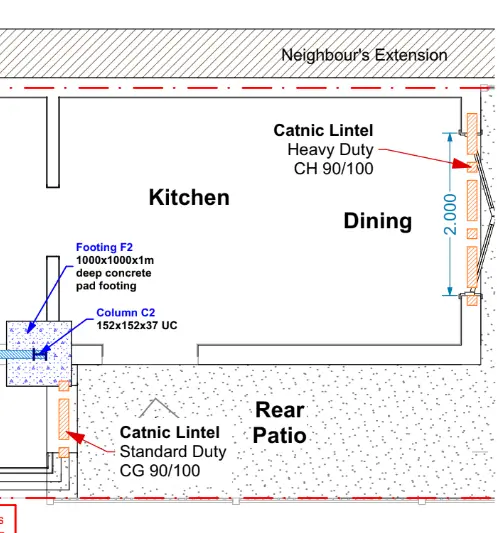

Appreciate any advice/pointers on this because my Structural Engineer has sent calculations for a door and aperture that don't add up I think (and hasn't responded for 2 days).

We want to install sliding patio doors in the garden-facing back room which has an external width of 3430mm (location: London).

Room + Walls:

- One storey room with flat, timber + felt roof (no roof lights, only walked on for window washing/repairs etc)

- Boiler in the corner nearest the neighbour's extension

- Walls are 9"/228.6mm wide and solid (no cavity)

- Currently has a 1188.72 x 640.08 window (will be removed)

We asked that the door be located off-center so that it's closest to the rear-patio side.

This would leave approximately 895.2 mm on the side nearest the neighbour's extension which also has the boiler in the corner.

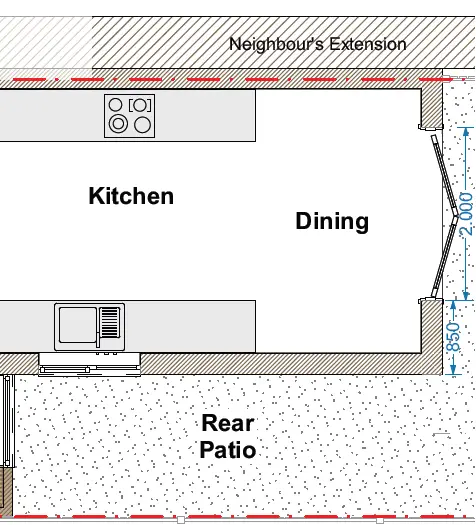

The S Engineer has returned drawings showing a 850mm gap on the rear-patio side and a door width of 2000mm.

If we use these measurements, the door overlaps with the boiler.

The only way to make a 2000mm fit is if the gap from the rear-patio corner is approx. 606mm instead of 850mm.

If we stick with 850mm then we'd have to get a smaller door or move the boiler which we prefer not doing.

Does the 850mm gap make sense and can it be reduced at all? Is there a way to still fit a 2000mm door without having to move the boiler?

Additionally, a builder mentioned that a Catnic Lintel Heavy Duty CH 90/100 is not right for a solid wall... can anyone advice on this?

We want to install sliding patio doors in the garden-facing back room which has an external width of 3430mm (location: London).

Room + Walls:

- One storey room with flat, timber + felt roof (no roof lights, only walked on for window washing/repairs etc)

- Boiler in the corner nearest the neighbour's extension

- Walls are 9"/228.6mm wide and solid (no cavity)

- Currently has a 1188.72 x 640.08 window (will be removed)

We asked that the door be located off-center so that it's closest to the rear-patio side.

This would leave approximately 895.2 mm on the side nearest the neighbour's extension which also has the boiler in the corner.

The S Engineer has returned drawings showing a 850mm gap on the rear-patio side and a door width of 2000mm.

If we use these measurements, the door overlaps with the boiler.

The only way to make a 2000mm fit is if the gap from the rear-patio corner is approx. 606mm instead of 850mm.

If we stick with 850mm then we'd have to get a smaller door or move the boiler which we prefer not doing.

Does the 850mm gap make sense and can it be reduced at all? Is there a way to still fit a 2000mm door without having to move the boiler?

Additionally, a builder mentioned that a Catnic Lintel Heavy Duty CH 90/100 is not right for a solid wall... can anyone advice on this?

Last edited: