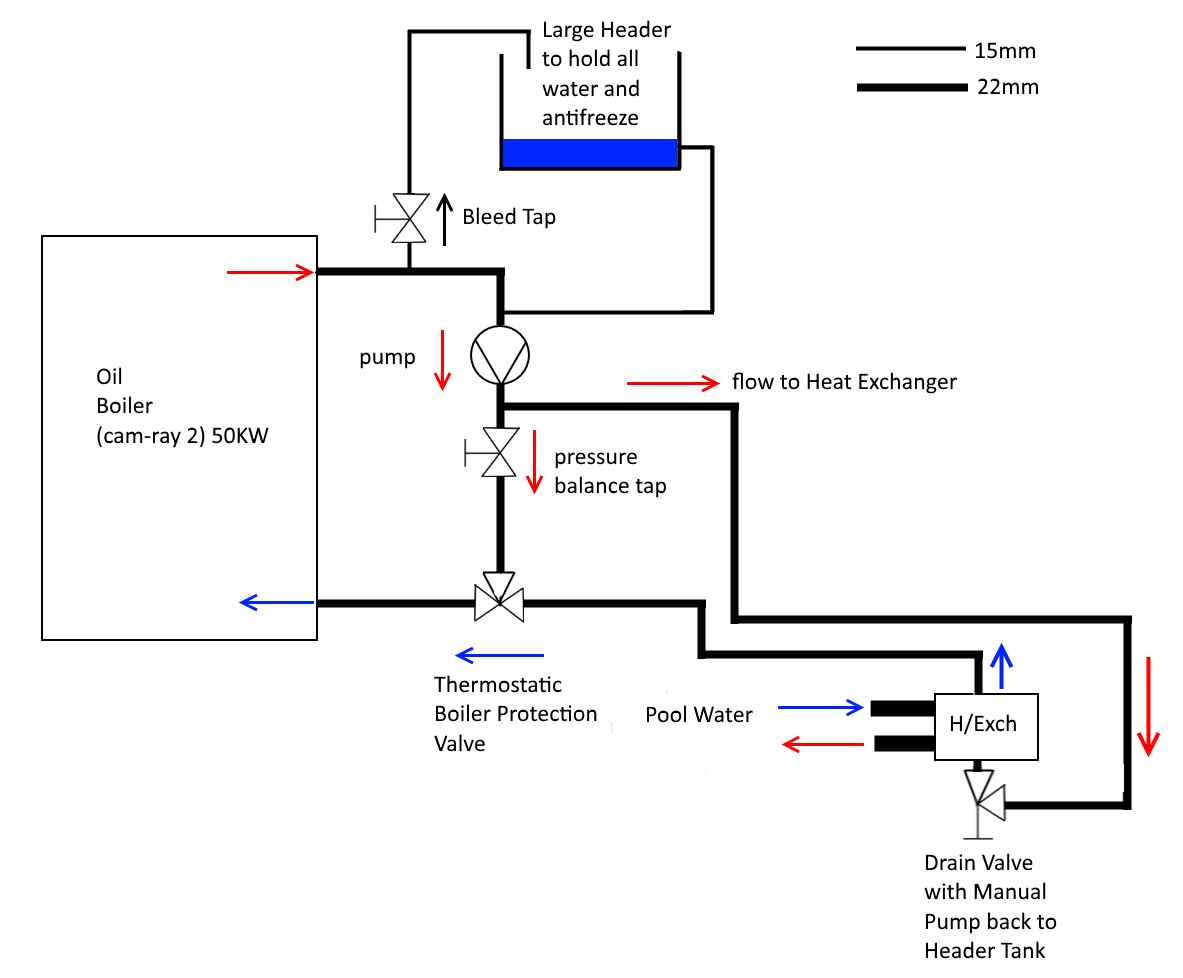

I'm installing an old oil fired boiler to heat the kids' pool. This is my starting diagram and I'd like a bit of input please. I've not done this before and some things are counter-intuitive so I'm checking.

It is outside (in a shed) so I'll have to have anti-freeze of some kind in the system. This means it must be contained as I can't empty it down the drain. The header tank will be able to hold all the water in the system and the drain valve at the lowest point will permit pumping the water back to the header tank via a hose manually. The bleed valve at the top of the system will empty back to the header.

The pump is pumping downwards ... is that ok?

The Thermostaic Boiler Protection valve says both feeds must be near equal pressure, hence the pressure balance tap (valve to restrict flow - don't know what you call it )

)

Any suggestions or glaring omissions or just plain incorrect? Constructive help is much appreciated!

It is outside (in a shed) so I'll have to have anti-freeze of some kind in the system. This means it must be contained as I can't empty it down the drain. The header tank will be able to hold all the water in the system and the drain valve at the lowest point will permit pumping the water back to the header tank via a hose manually. The bleed valve at the top of the system will empty back to the header.

The pump is pumping downwards ... is that ok?

The Thermostaic Boiler Protection valve says both feeds must be near equal pressure, hence the pressure balance tap (valve to restrict flow - don't know what you call it

Any suggestions or glaring omissions or just plain incorrect? Constructive help is much appreciated!