You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Potterton ProMax Combi - Flush and Clean Sludge (micro-bore system)

- Thread starter john2k

- Start date

The pipe that I drew a red arrow on in the attached pictures attached in my previous post is the only pipe that i can see gets hot when I turn CH on. I'm not sure if this is the return or the flow or does my system only have one pipe doing both flow and return? I am assuming the magnaclean needs to be installed on the return pipe. Is there any way for me to determine if this is the pipe that I need to cut?

Turn heating on, the first pipe to get warm us the flow. The one that slowly warms up over the next 20 mins is the return. Fit filter to that one

There's a diagram in your manual which indicates exactly what all of the pipes are. Post a picture of it if you have any questions.

Better that than someone on the internet inadvertently advises you to cut into your gas pipe.

Thanks, I will post pics later of the user manual showing the pipes.

Your heating return is the 22mm pipe at far right side of boiler, (the last one before the 15mm pressure relief pipe which is in 15mm copper) the pic shows it coming from boiler and coming out and running vertically up right side of boiler casing.

The one that runs horizontallly that you put red mark on is the heating flow.

The one that runs horizontallly that you put red mark on is the heating flow.

Pardon my interruption but I did a professional flushing course in conjunction with fernox and we were told,mind you this was 12 years ago,that, you cannot flush micro bore pipe because the cross- sectional area of the pipe bore is not large enough to support a large flow of water.Just thought I'd

mention it.Bob

mention it.Bob

Your heating return is the 22mm pipe at far right side of boiler, (the last one before the 15mm pressure relief pipe which is in 15mm copper) the pic shows it coming from boiler and coming out and running vertically up right side of boiler casing.

The one that runs horizontallly that you put red mark on is the heating flow.

Thanks McCombi, it seems you are correct, I had a look in the user manual and also I felt the return pipe and it is the pipe that gets hot after a little while as water starts returning to the boiler.

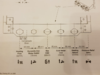

I have attached a diagram from the user manual. I have also attached some photos showing a close-up of the return pipe. Unfortunately the return pipe seems like its done in such a awkward way that cutting it with any tool even the rotating cutting tool will prove to be impossible. As you can probably see in the photos, the flow runs horizontally across in front of the return and then goes up in a cavity along the side of the boiler. Along this same side of the boiler the return comes down and then elbows across, and then elbows back up creating a U shape as it enters the boiler. The straight section of return pipe between the two elbows that runs horizontally parallel to the flow is very short and is essentially at the same height as the flow. So the flow is restricting access to it as the return is behind the flow. Further to that to make it even worse, there is a 15mm pipe coming down vertically right in the middle where flow and return are parallel horizontally. This 15mm I believe is pressure relief maybe.

So the question is how do I even cut the return to install the magnaclean? There is plenty of space below in the boiler cupboard so what ideally needs to happen is that the return pipe needs to go much further down then elbow and go back up and as it goes back up towards the boiler that will create the space I need for the magnaclean. But the problem is how do I cut this pipe? Only thing I can think of is to actually de-solder the elbows completely and attach some new pipe work. But seeing as its such a tight place and there is wood and other pipes in the way, putting any kind of flame on it seems a bit risk. I have done copper solder joints and am confident in doing that but not sure how I will even go about de-soldering and soldering in this tight area without damaging anything.

Any advice would be much appreciated. Thanks.

I'd be tempted to get a pipe slice on that short 22mm stretch that comes out of the back of the boiler and then join a new elbow to it.

You may find it easier to remove the return pipe completely from the boiler, then you can solder your new "U-bend" away from the boiler where you're not so tight for space.

You may find it easier to remove the return pipe completely from the boiler, then you can solder your new "U-bend" away from the boiler where you're not so tight for space.

I'd be tempted to get a pipe slice on that short 22mm stretch that comes out of the back of the boiler and then join a new elbow to it.

You may find it easier to remove the return pipe completely from the boiler, then you can solder your new "U-bend" away from the boiler where you're not so tight for space.

Do you mean cut it where i've drawn a red line in the following attached picture? And then completely remove the nut union connection to the boiler? I will need to see if I can fit a pipe cutter in there. Even if I could, soldering in a coupler in there would be a bit difficult as it is so close to other pipes and the wood. Is there any sort of shield protection for soldering in tight spaces like that?

I actually meant cut the horizontal piece that comes out of the boiler, but I guess you could cut there too.

Search for "solder mat", Rothenberger do some decent ones.

The horizontal short piece i really tight to get to, its so tight that i cannot even get my hand in there to touch that pipe. If I cut it on the red line that I drew as it's coming back down the side of the boiler, can I use a push fit coupler to extend the pipe down or should I solder a new coupler in?

You shouldn't use pushfit so close to the boiler.

Solder would be preferred but a brass compression fitting would be acceptable if you can get an adjustable in.

Edit: I guess you could use copper pushfit but it'd be a bit of a bodge job imo

Solder would be preferred but a brass compression fitting would be acceptable if you can get an adjustable in.

Edit: I guess you could use copper pushfit but it'd be a bit of a bodge job imo

Last edited:

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 9

- Views

- 6K

- Replies

- 8

- Views

- 10K

- Replies

- 2

- Views

- 3K