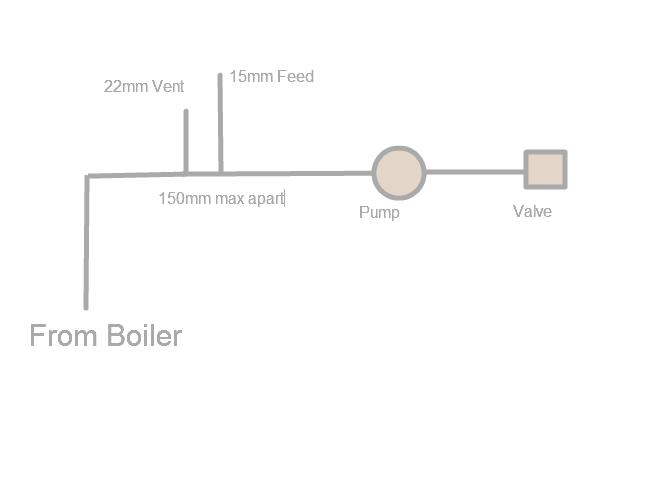

New boiler installed (May) -installer didn't check suitability of pipework - apologised - would return to fix it - still waiting. The main features of the pipework - feed and vent pipes are connected to the HW circuit -return and flow respectively - pump on the return side. So, at present - a fully pumped system alongside a C plan pipe framework!

When HW is on the CH is heated as well - no pump over.

When CH is selected - pumping over - WHY ?? - more importantly what solution can anyone give me. Is it because an S plan has not been installed or can there be another reason causing this problem.

I have checked for blockages - none

Cut down the pump speed - no effect

There is no room to heighten the vent pipe

As the CH works perfectively when HW is selected then ,surely, the pipework design is okay.

Can anyone help to determine where to site the zone valve when I get round to installing an S plan layout. According to the plan it should be fitted on the HW flow pipe.

Should it be fitted between the boiler and the vent pipe ,or, between the vent pipe and the hot water cylinder ?? Remembering that my pipework is not as indicated in the S plan schematic.

When HW is on the CH is heated as well - no pump over.

When CH is selected - pumping over - WHY ?? - more importantly what solution can anyone give me. Is it because an S plan has not been installed or can there be another reason causing this problem.

I have checked for blockages - none

Cut down the pump speed - no effect

There is no room to heighten the vent pipe

As the CH works perfectively when HW is selected then ,surely, the pipework design is okay.

Can anyone help to determine where to site the zone valve when I get round to installing an S plan layout. According to the plan it should be fitted on the HW flow pipe.

Should it be fitted between the boiler and the vent pipe ,or, between the vent pipe and the hot water cylinder ?? Remembering that my pipework is not as indicated in the S plan schematic.