I have squeaky, old stairs. At least 100 years old and repaired / new treads added in a odd way.

Each tread is now made of 2 pieces of wood and moves/squeaks independently of each other.

Plan is to cut 18mm ply and glue and screw this to the underside using this https://www.screwfix.com/p/evo-stik-polyurethane-wood-adhesive-310ml/40778

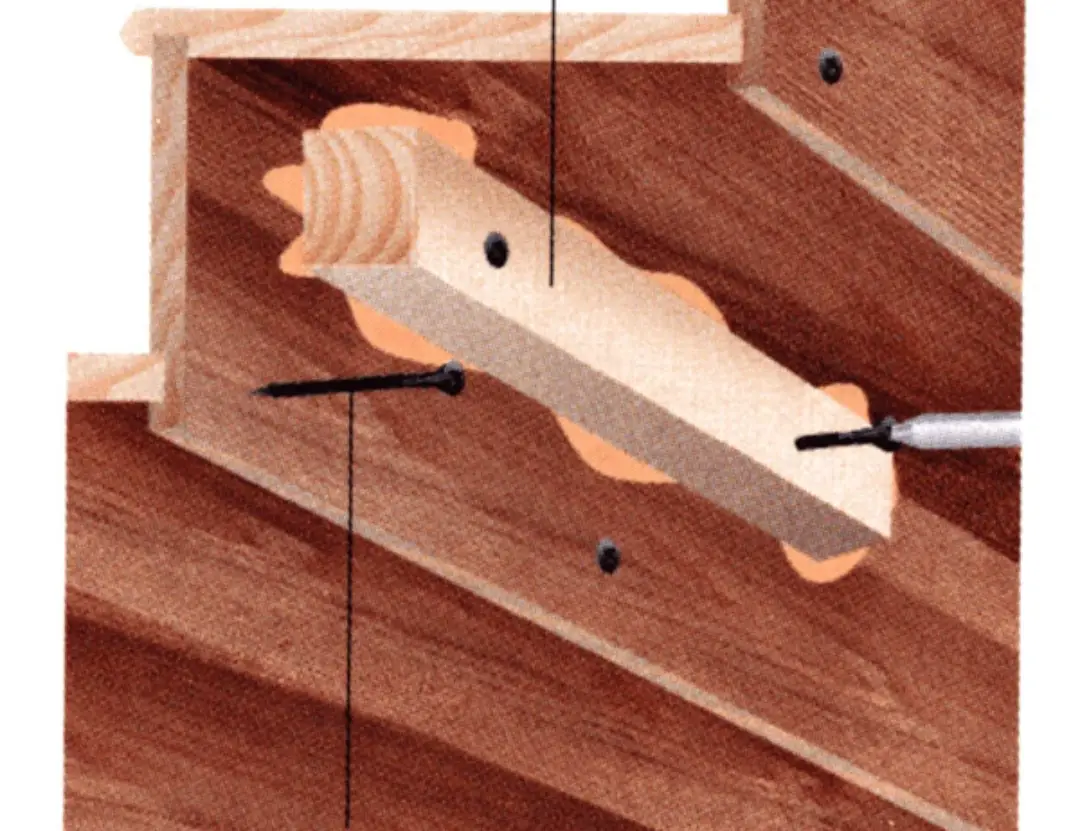

Once done, then add 44x44mm batons glued /screwed through the ply and tread, and glued / screwed to the risers. This is to replace the missing glue blocks and wedges.

Like this but up into the tread as well as into the riser.

Finally glue and screw more batons to the ply and stringers to support the ply.

I'm hoping this will sort out the creaks.

Questions:

1. Is the EVO-STIK POLYURETHANE WOOD ADHESIVE a good choice of glue? Is there a better one?

2. For the screws going through the ply into the treads. Ply is 18mm, treads are 23mm. Total thickness 41mm. What length screw and what diameter would you suggest? 30mm or 35mm? What width? I will drill pilot holes.

3. For the screws going through the batons, ply and tread (23mm + 18mm + 44mm) =85mm. What length and width screw?

Cheers!

Each tread is now made of 2 pieces of wood and moves/squeaks independently of each other.

Plan is to cut 18mm ply and glue and screw this to the underside using this https://www.screwfix.com/p/evo-stik-polyurethane-wood-adhesive-310ml/40778

Once done, then add 44x44mm batons glued /screwed through the ply and tread, and glued / screwed to the risers. This is to replace the missing glue blocks and wedges.

Like this but up into the tread as well as into the riser.

Finally glue and screw more batons to the ply and stringers to support the ply.

I'm hoping this will sort out the creaks.

Questions:

1. Is the EVO-STIK POLYURETHANE WOOD ADHESIVE a good choice of glue? Is there a better one?

2. For the screws going through the ply into the treads. Ply is 18mm, treads are 23mm. Total thickness 41mm. What length screw and what diameter would you suggest? 30mm or 35mm? What width? I will drill pilot holes.

3. For the screws going through the batons, ply and tread (23mm + 18mm + 44mm) =85mm. What length and width screw?

Cheers!