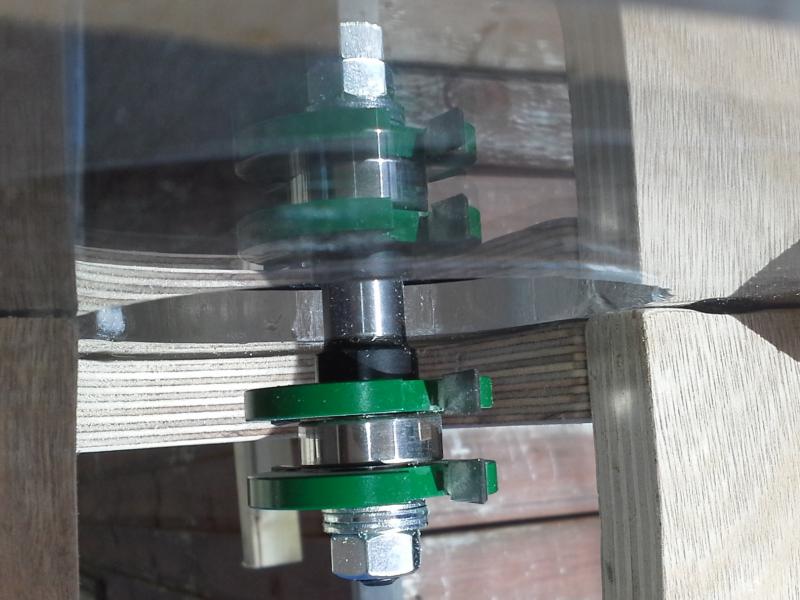

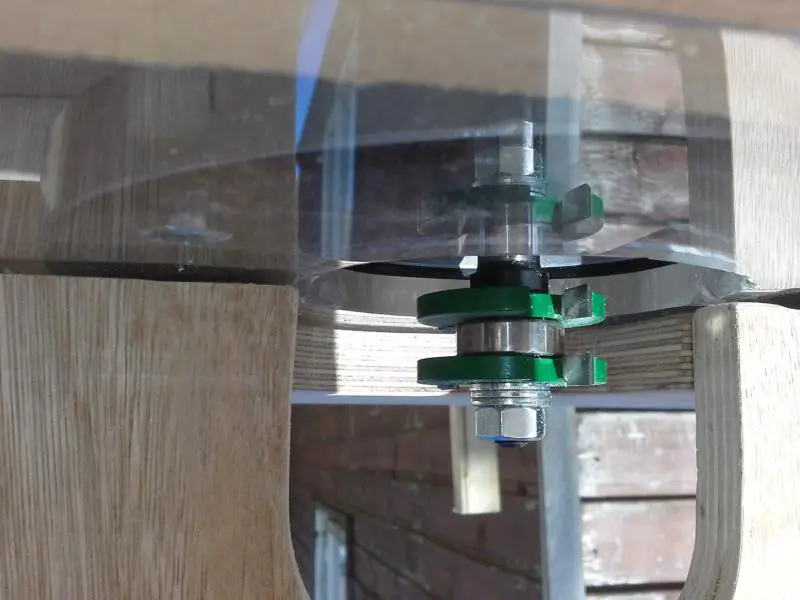

I have started practice runs for making shaker doors for my kitchen makeover, using a similar cutter this this fromTrend. New to routers and this is first time I have used table I have made.

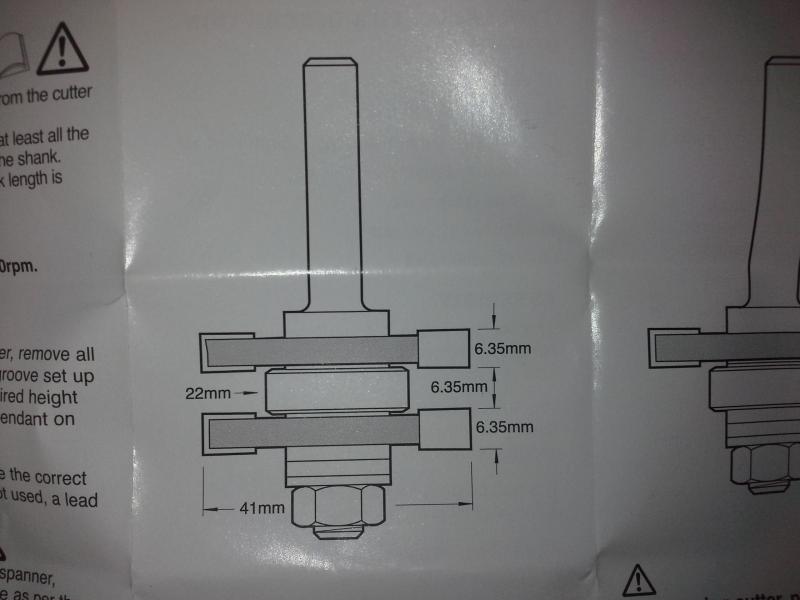

My first school boy error was to not read box correctly for cutter. I was planning on using oak 4x1 for stile & rail, approx 21mm. Cutter says maximum 18mm. I know im a numpty, dont think local yard does thinner stock. So, are there any ideas as to how to work with this cutter or buy another expensive bit?

My first school boy error was to not read box correctly for cutter. I was planning on using oak 4x1 for stile & rail, approx 21mm. Cutter says maximum 18mm. I know im a numpty, dont think local yard does thinner stock. So, are there any ideas as to how to work with this cutter or buy another expensive bit?