Hey guys,

First post so please be gentle! Its on a subject that seems to be a bit of a taboo around here - downlights.

Id better set the scene...

I recently got the keys to my first home (a new build apartment) which I am doing a fair bit of work on before I move in, including multiroom audio and video distribution and changes to the lighting. It is quite a unique apartment as it is in a 3 storey building, but covers half of the top 2 stories and has its own front door on the ground floor. The ground floor is one apartment and then the top two floors are split in half to create two mirrored apartments. So at no point is there another dwelling above mine.

Does that make sense?!

Id better add a bit about myself aswell. I am not an electrician but I run all kinds of cables and do installations of various pieces of electronic equipment (including hardwiring) for a living. This is mostly done overseas in an environment where regulations dont apply so much, but I will avoid going into details about that.

Ok, the downlighters...

These will be fitted into a number of rooms, the ceiling construction is plasterboard onto wooden joists. I am using 230v sealed unit downlighters with 90minute fire rating. I will be replacing all the bulbs with 35w.

So the first question is, am I using suitable units and is this notifiable to the building regulators?

One of the rooms that I am intending to have the lights in is the kitchen. Obviously I cant terminate these myself but is it allowed for me to cut the holes, run the cable in and leave hanging for a qualified sparky to come in and terminate/test? How would you electricians feel about doing the job? Would you want to run the cable yourself?

There is also a bay window in the kitchen where I would like to have 2 LV lights on the same circuit as the under unit lights. Recessed lights are a no go so I have surface mounts. I have already cut the plaster and put some low profile trunking in place ready for these. Is this the correct way of doing it? I didnt like the idea of having the cables from the transformer plastered directly into the wall! I have already pulled in a 1.5mm2 T+E between the void were the transformer will be located and the switch for the under unit lights.

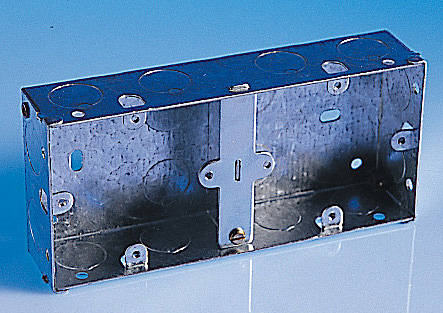

Also in the kitchen I have a wall mounted TV. To get power to this I was intending to have a fused spur at outlet height with flex running up to a backbox behind the TV. The flex would be protected in the wall cavity by flexible conduit and glanded into the backboxes. Is this adequate protection? And again, if I were to run the cable and leave ready to terminate would this be ok? Finally, on this part of my installation, does a double gang single socket with single fused spur exist (kind of like a cooker unit but 13A) or will I need to cut two separate single gang holes as I would like a socket outlet next to the fused spur.

Finally, there is a two-way circuit between the entrance hall and first floor landing. Is it possible to separate the entrance hall lights from the circuit to put them on there own switch? And is this possible using the existing wiring?

Oh, I did say finally, but ive just thought of something else! Could anyone suggest somewhere to get dimmer switches for two-way circuits? Am looking at single point dimmers and slave type setups aswell.

Sorry for the essay but any help/advice on the above will be hugely appreciated!

Many thanks

John

EDIT: Just to add, all materials would be provided by myself (light units, cable, earth sleeve, cable clips, MK faceplates, dry wall backboxes etc) so the electrician in theory would only need to terminate/test and nothing else. Again, is this something you electricians would be happy with?

First post so please be gentle! Its on a subject that seems to be a bit of a taboo around here - downlights.

Id better set the scene...

I recently got the keys to my first home (a new build apartment) which I am doing a fair bit of work on before I move in, including multiroom audio and video distribution and changes to the lighting. It is quite a unique apartment as it is in a 3 storey building, but covers half of the top 2 stories and has its own front door on the ground floor. The ground floor is one apartment and then the top two floors are split in half to create two mirrored apartments. So at no point is there another dwelling above mine.

Does that make sense?!

Id better add a bit about myself aswell. I am not an electrician but I run all kinds of cables and do installations of various pieces of electronic equipment (including hardwiring) for a living. This is mostly done overseas in an environment where regulations dont apply so much, but I will avoid going into details about that.

Ok, the downlighters...

These will be fitted into a number of rooms, the ceiling construction is plasterboard onto wooden joists. I am using 230v sealed unit downlighters with 90minute fire rating. I will be replacing all the bulbs with 35w.

So the first question is, am I using suitable units and is this notifiable to the building regulators?

One of the rooms that I am intending to have the lights in is the kitchen. Obviously I cant terminate these myself but is it allowed for me to cut the holes, run the cable in and leave hanging for a qualified sparky to come in and terminate/test? How would you electricians feel about doing the job? Would you want to run the cable yourself?

There is also a bay window in the kitchen where I would like to have 2 LV lights on the same circuit as the under unit lights. Recessed lights are a no go so I have surface mounts. I have already cut the plaster and put some low profile trunking in place ready for these. Is this the correct way of doing it? I didnt like the idea of having the cables from the transformer plastered directly into the wall! I have already pulled in a 1.5mm2 T+E between the void were the transformer will be located and the switch for the under unit lights.

Also in the kitchen I have a wall mounted TV. To get power to this I was intending to have a fused spur at outlet height with flex running up to a backbox behind the TV. The flex would be protected in the wall cavity by flexible conduit and glanded into the backboxes. Is this adequate protection? And again, if I were to run the cable and leave ready to terminate would this be ok? Finally, on this part of my installation, does a double gang single socket with single fused spur exist (kind of like a cooker unit but 13A) or will I need to cut two separate single gang holes as I would like a socket outlet next to the fused spur.

Finally, there is a two-way circuit between the entrance hall and first floor landing. Is it possible to separate the entrance hall lights from the circuit to put them on there own switch? And is this possible using the existing wiring?

Oh, I did say finally, but ive just thought of something else! Could anyone suggest somewhere to get dimmer switches for two-way circuits? Am looking at single point dimmers and slave type setups aswell.

Sorry for the essay but any help/advice on the above will be hugely appreciated!

Many thanks

John

EDIT: Just to add, all materials would be provided by myself (light units, cable, earth sleeve, cable clips, MK faceplates, dry wall backboxes etc) so the electrician in theory would only need to terminate/test and nothing else. Again, is this something you electricians would be happy with?