While some of the general problems with DIY work include not stripping cables to a workable length, using earth sleeving, grommets, etc...

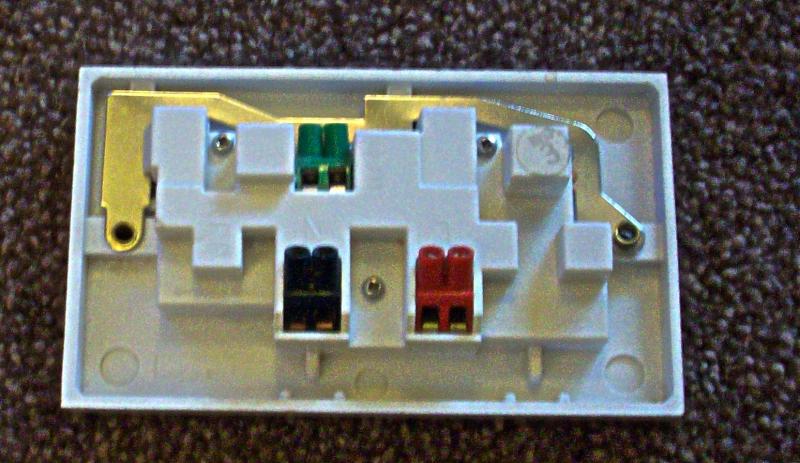

...the most common problem is tightening the wires to the terminals.

People just can't do it.

All too often, some handyman will replace a socket. You feel compelled to check it if it's an installation you've been heavily involved with, and the wires just fall out, or you can easily tighten up the screws more.

The other problem is wires snapping at the terminal, where an end needed restripping. Or sometimes an end needed doubling over to give it more strength.

Related to this is trapping the insulation under the screw.

All the time householders/builders/plumbers claim they have connected something 'for you', but you have to check it if it's part of your work.

There's not a lot on this forum (as far as I know) on basic techniques as connecting a wire to a terminal. It's seemingly so basic, yet people can't do it.

Is it that they're not strong enough, or don't want to damage the wire? Or just not thinking?

...the most common problem is tightening the wires to the terminals.

People just can't do it.

All too often, some handyman will replace a socket. You feel compelled to check it if it's an installation you've been heavily involved with, and the wires just fall out, or you can easily tighten up the screws more.

The other problem is wires snapping at the terminal, where an end needed restripping. Or sometimes an end needed doubling over to give it more strength.

Related to this is trapping the insulation under the screw.

All the time householders/builders/plumbers claim they have connected something 'for you', but you have to check it if it's part of your work.

There's not a lot on this forum (as far as I know) on basic techniques as connecting a wire to a terminal. It's seemingly so basic, yet people can't do it.

Is it that they're not strong enough, or don't want to damage the wire? Or just not thinking?